A rigid support method for machining thin-walled cavity parts

A technology of rigid support and parts processing, which is applied in the direction of metal processing equipment, metal processing machinery parts, supports, etc., can solve the problems of precision error, low production efficiency, inability to fully fit inside the cavity and lack of support, etc., to achieve reduction Production cost and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

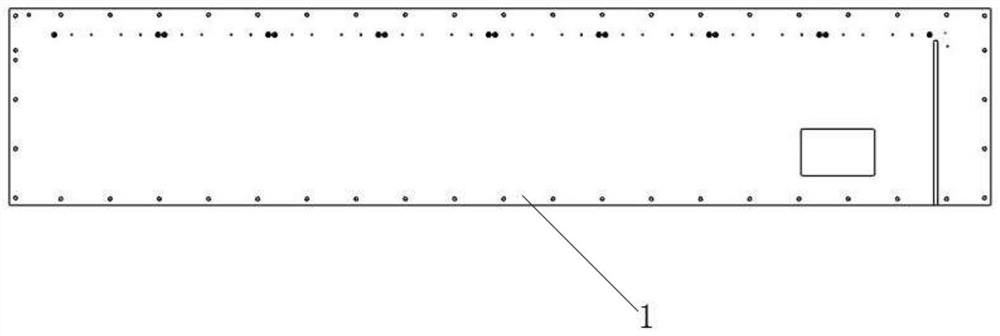

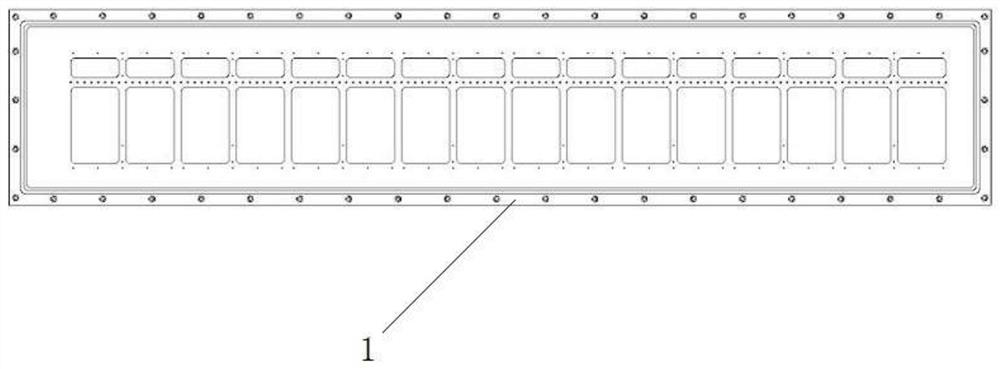

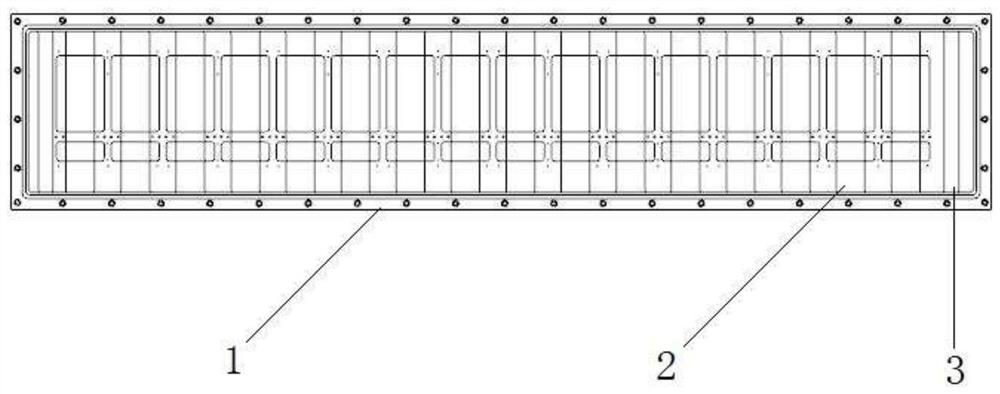

[0028] Such as Figure 1 to Figure 8 shown.

[0029] A method for processing rigid supports for thin-walled cavity parts of the present invention comprises the following steps:

[0030] Step 1: installing a flexible base layer A2 on each cavity in the middle of the thin-walled cavity part 1, and installing a flexible base layer B3 on the cavities at both ends of the thin-walled cavity part 1;

[0031] Step 2: apply a curing agent on the base layer A2 to form a curing layer A4, and apply a curing agent on the base layer B3 to form a curing layer B5;

[0032] Step 3: Install several supporting tooling parts A6 on the curing layer A4 correspondingly, and two supporting tooling parts B7 respectively correspondingly installing on the curing layer B5, so that the curing layer A4 and the curing layer B5 are naturally dried under natural...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com