Bolt sequential tightening tool applied to lithium battery

A lithium battery and bolt technology, which is applied in the field of bolt sequential tightening tooling, can solve the problems of repeated screwing of bolts, lack of specifications, and inability of employees to adjust in time, so as to improve the standardization and pass rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

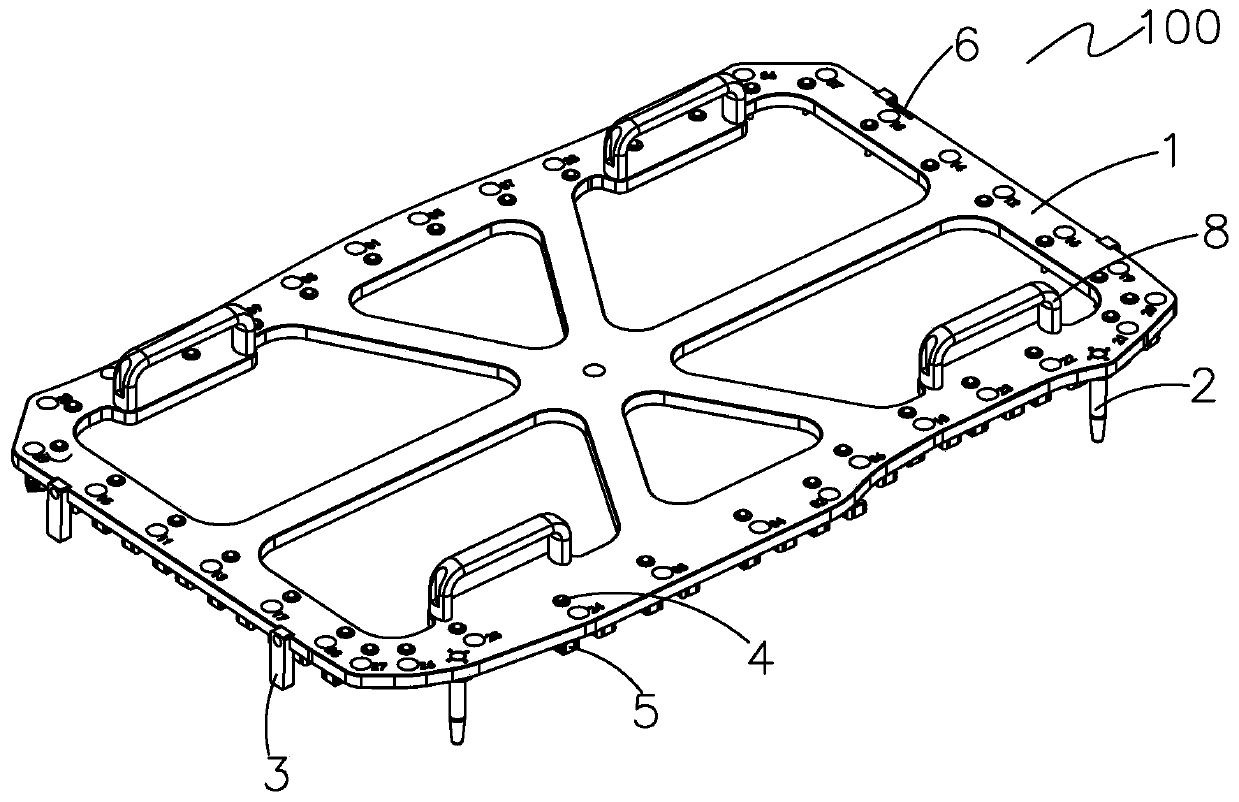

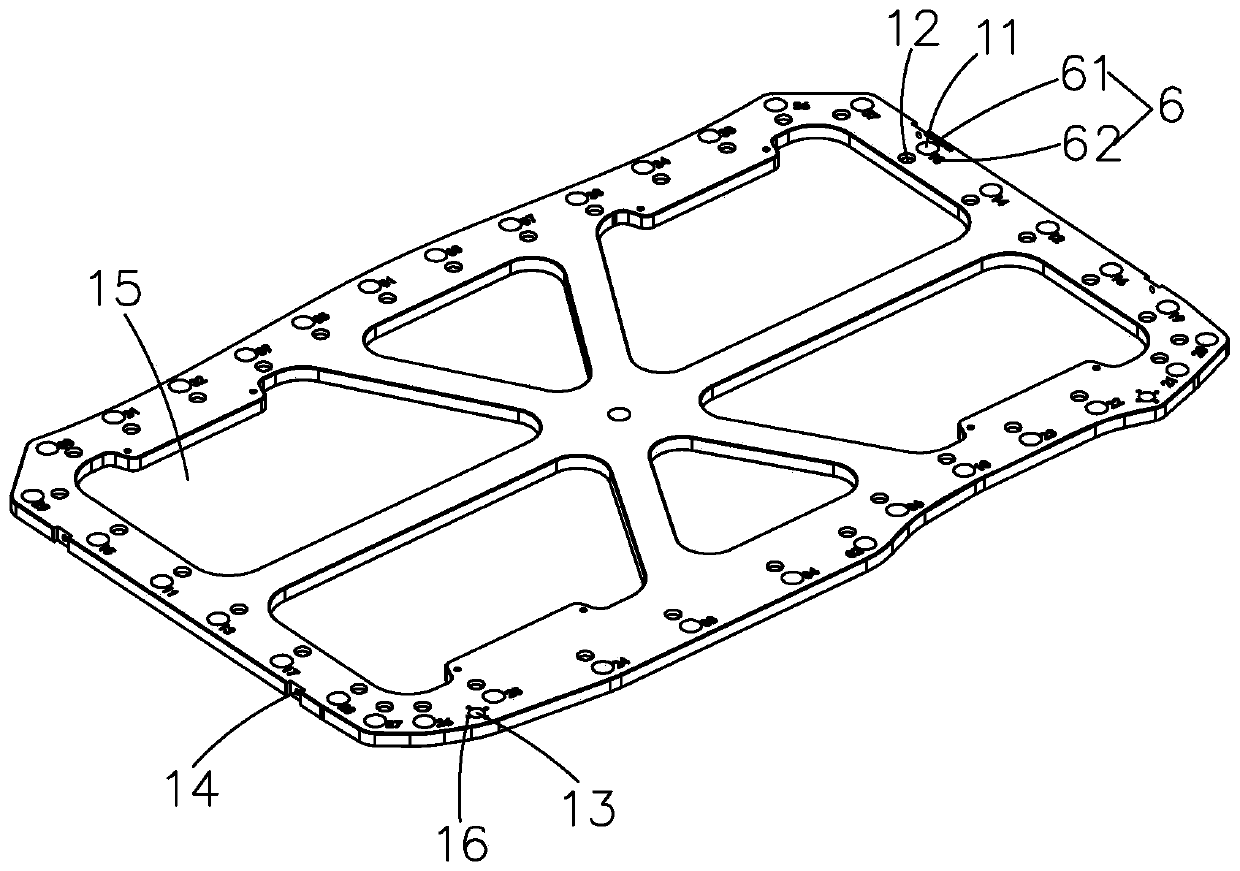

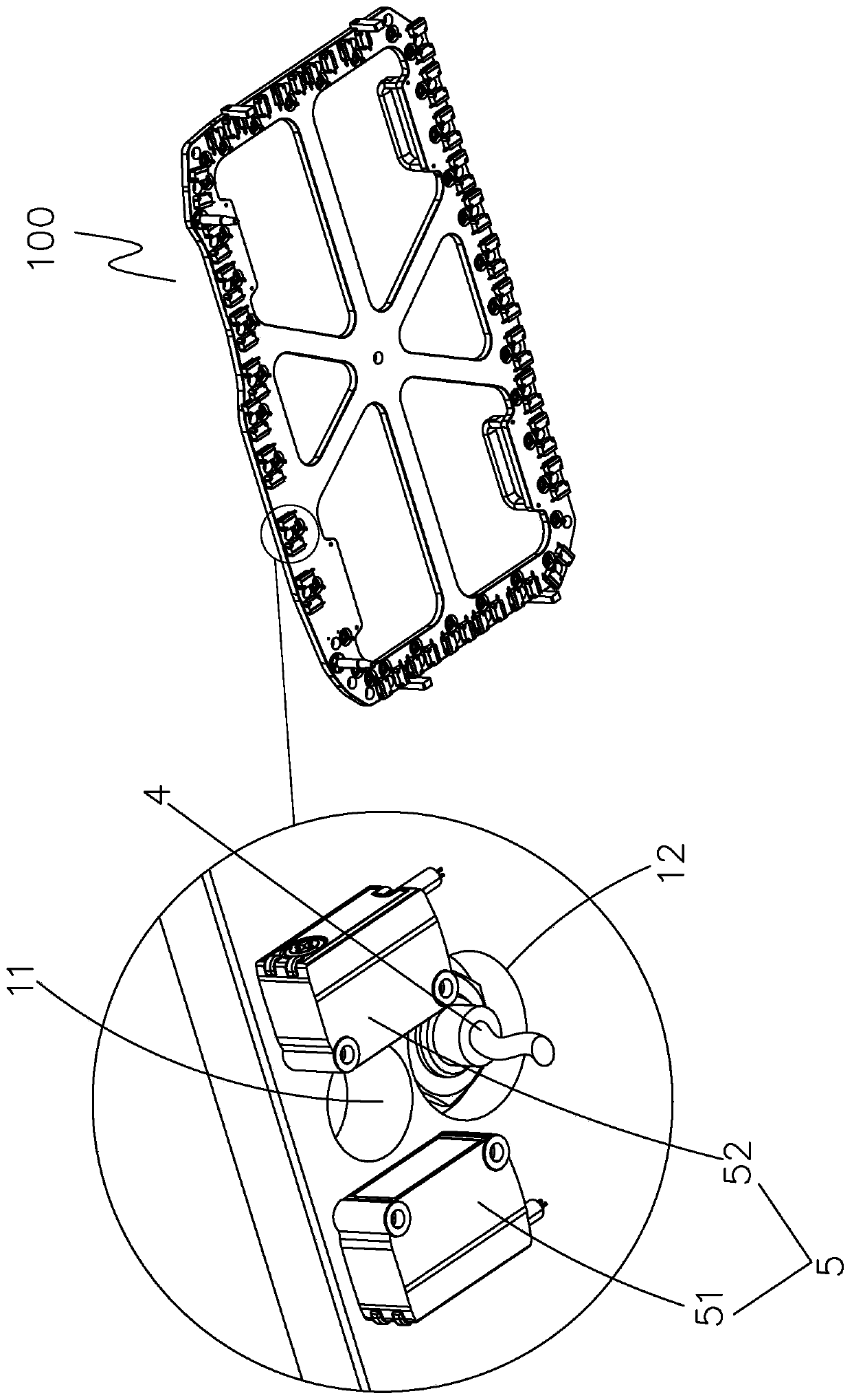

[0029] Please refer to Figure 1 to Figure 5 As shown, a preferred embodiment of a bolt sequence tightening tool 100 applied to a lithium battery in the present invention includes:

[0030] An aluminum shell 1 is longitudinally provided with a plurality of first light holes 11 for tightening bolts, a plurality of second light holes 12 and two third light holes 13 for installing indicator lights 4, and the side is provided with at least Four notches 14; a plurality of threaded holes 16 are arranged around the third light hole 13;

[0031] Two guide pins 2 are inserted into the third light hole 13, and locked on the threaded hole 16 by bolts; the guide pin 2 is used to guide the tightening tool 100 so that it is compatible with the lithium battery 9 to be assembled. carry out alignment;

[0032] At least four support blocks 3 are locked to the side of the housing 1 through the notches 14; the support blocks 3 are used to support the tightening tool 100 on the lithium battery 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com