Warehouse applicable to fertilizer storage

A fertilizer and warehouse technology, applied in the warehouse field of fertilizer storage, can solve problems such as affecting the economic benefits of enterprises, wasting warehouse volume, and reducing enterprise income estimates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

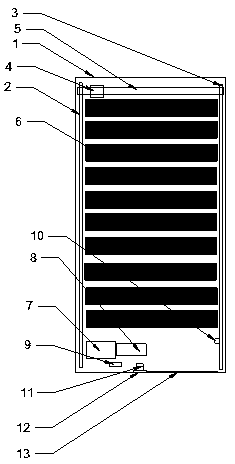

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, this is suitable for fertilizer storage warehouses, including fertilizer storage warehouse 1, left lifting track 2, right lifting track 3, compressed fertilizer crane 4, compressed fertilizer crane track 5, fertilizer stacking area 6, and fertilizer compression area 7. Fertilizer unloading area 8 to be compressed, fertilizer compressor console 9, crane console 10, gate motor 11, gate transmission device 12 and gate 13, the fertilizer storage warehouse 1 has a rectangular through hole on the surface to install the gate 13. The gate 13 is connected to the gate transmission device 12 through gears. The gate transmission device 12 is fixed on the ground through screws. The gate transmission device 12 is connected to the gate motor 11 through bearings. The gate motor 11 is fixed on the ground through screws. The left side of the fertilizer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com