Forklift door frame and forklift

A forklift mast and mast technology, which is applied in the direction of lifting device, engine components, engine lubrication, etc., can solve the problems of difficult maintenance and high cost of roller structure, simplify the limit structure, reduce manufacturing cost, and improve maintenance convenience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

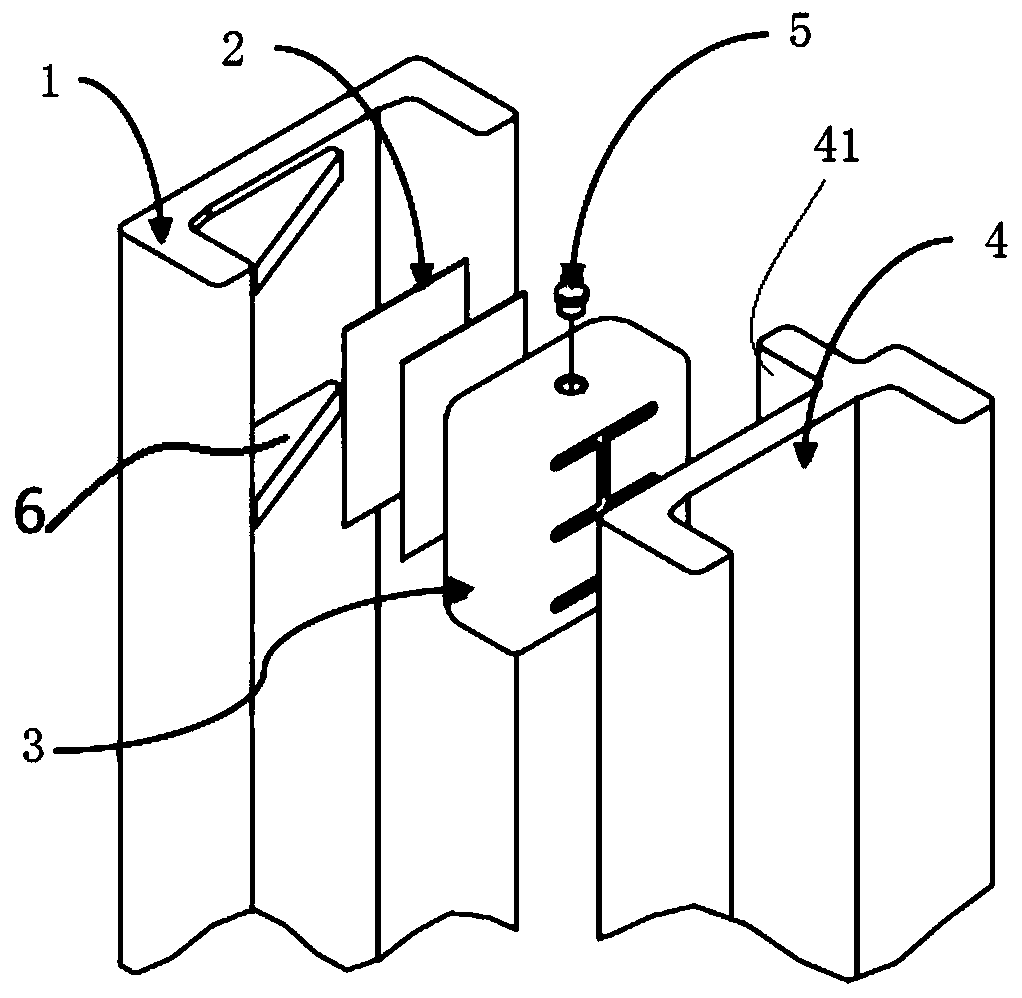

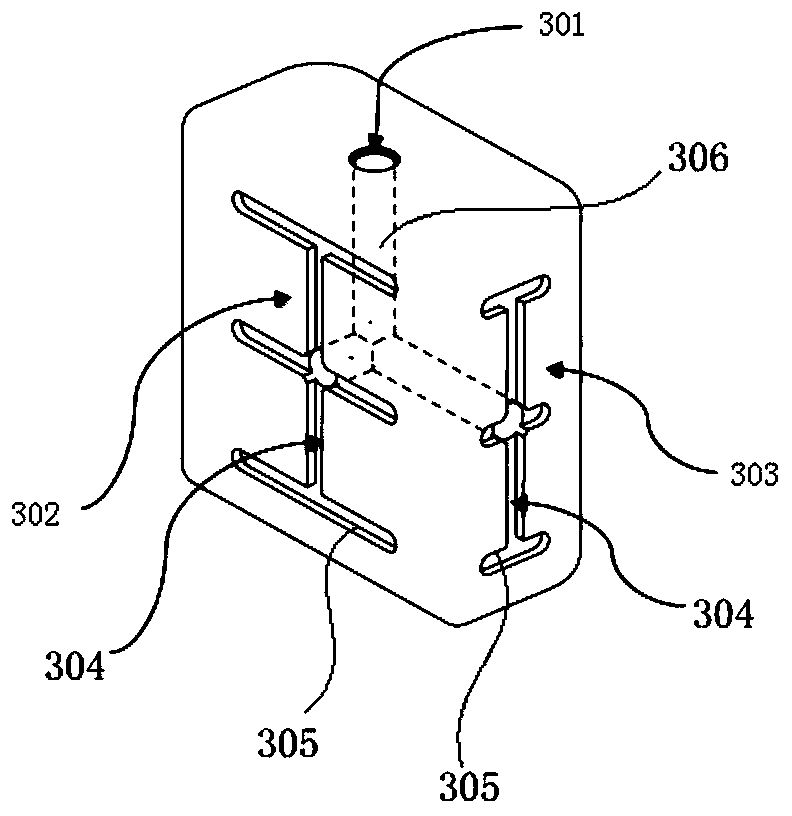

[0024] The specific implementation will be described below in conjunction with the accompanying drawings.

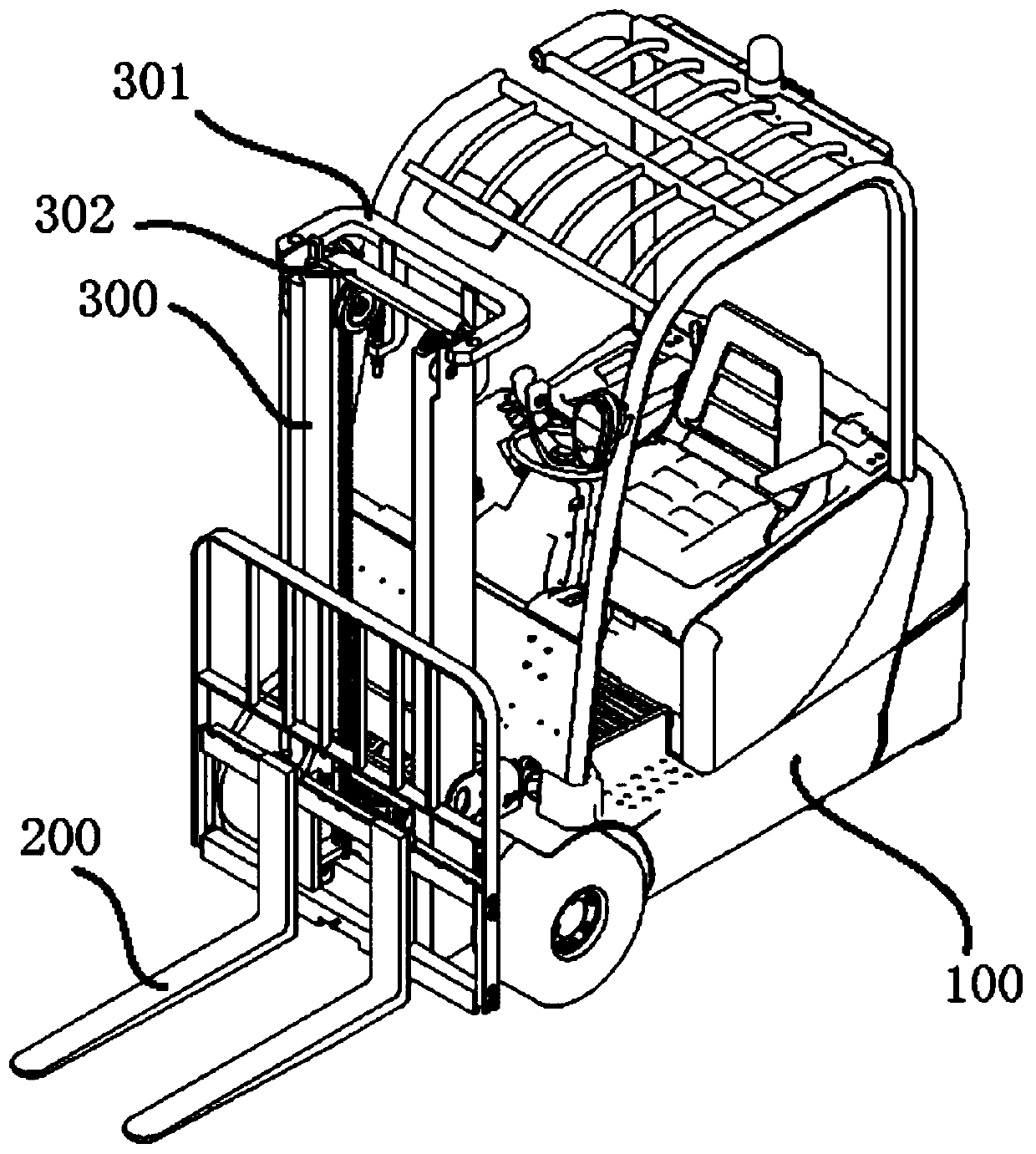

[0025] like figure 1 As shown, the forklift among the present invention comprises car body 100, and door frame 300 is installed on the front portion of car body, and cargo fork 200 is installed on door frame 300, and the lift of the inner side door frame in door frame relative outside door frame drives goods. Fork 200 lifts, thereby realizes the lifting effect of fork-loaded goods.

[0026] Depending on the lifting height, the forklift mast can be designed as a two-stage mast, a three-stage mast or even more levels of mast. The two-level mast includes the inner mast and the outer mast, and the mast in the three-level mast is usually called the inner mast, the middle mast, and the outer mast. The inner door frame and the outer door frame in the present invention are only relative between two adjacent door frames. In the two-stage mast, the inner mast in the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com