Automatic climbing frame system for cloth bag air pipe mounting

A technology for the installation of bag air ducts, which is applied in the direction of lifting devices, etc., can solve the problems of unfavorable, efficient and safe installation of bag air ducts 101, prone to safety problems, and low construction efficiency, so as to improve installation and construction efficiency, The effect of high degree of automation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

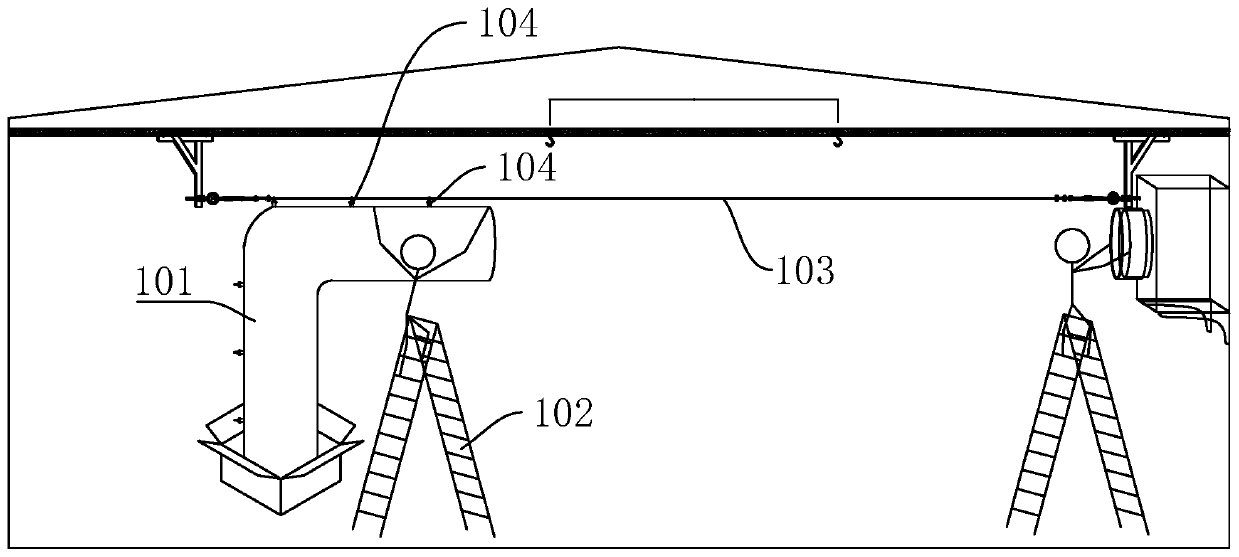

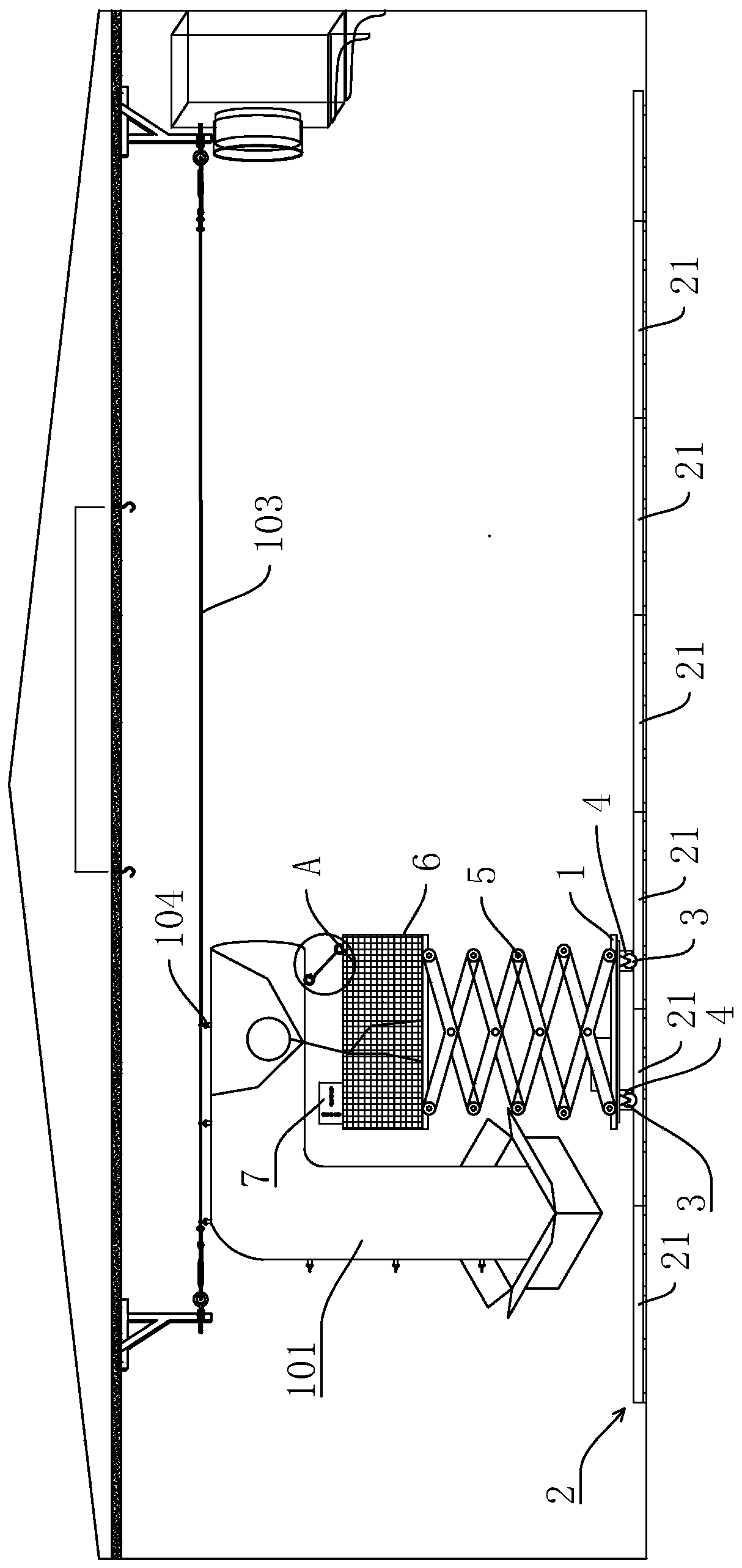

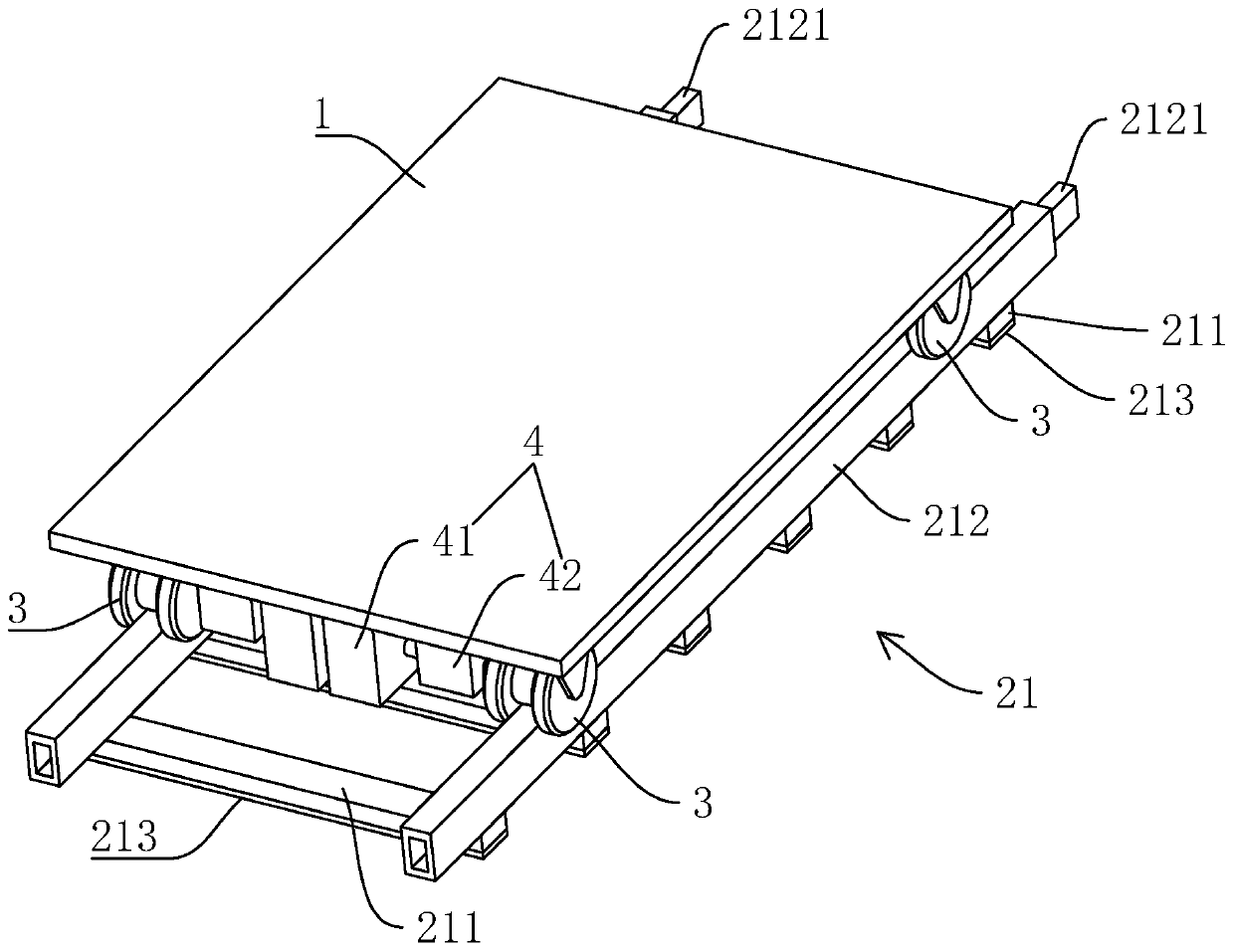

[0041] refer to figure 2 , is an automatic climbing frame system for installing a cloth bag air duct disclosed in the present invention, including: a bottom plate 1, a slide rail structure 2, a pulley 3, a driving structure 4, an electric scissor lift 5, a guardrail 6, and a control unit 7.

[0042] The slide rail structure 2 is laid on the ground and is located below the installation position of the bag air duct 101. Two rows of pulleys 3 are arranged on the bottom of the bottom plate 1. The pulleys 3 slide freely on the slide rail structure 2. The driving structure 4 is arranged on the bottom plate 1 and the pulleys. 3 and drives the pulley 3 to rotate forward and reverse.

[0043] The electric scissor lift 5 is installed on the bottom plate 1, and the guardrail 6 is arranged on the upper surface of the electric scissor lift 5. A control unit 7 is provided, and a plurality of buttons are arranged on the control unit 7, and the buttons are electrically connected with the dr...

Embodiment 2

[0056] refer to figure 2 with Image 6 , which is an automatic climbing frame system for installing a cloth bag air duct disclosed in the present invention, the difference from Embodiment 1 is that:

[0057] One side of the door leaf 61 is rotatably assembled with one side of the opening, and its rotation axis is vertically arranged. When the staff needs to stand on the electric scissor lift 5, the staff can first rotate the door leaf 61, so that the staff can enter the inside of the guardrail 6, and then turn and close the door leaf 61, so that the guardrail 6 forms a frame structure , has a good protective effect on the staff standing on the electric scissor lift 5, and is easy to operate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com