A kind of cobalt-nickel hydroxide sleeve-type modified carbon fiber composite material and its preparation method and application

A fiber composite material and hydroxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problem of easy agglomeration, performance reduction, metal hydroxide Poor conductivity and other problems, to achieve the effects of simplified process, clear active components, and high electrocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

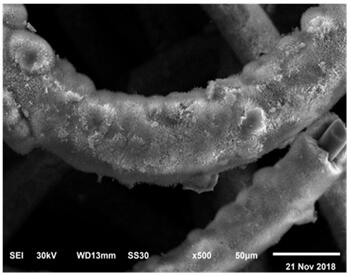

[0037] Take the polyacrylonitrile carbon felt (PAN) acidified by concentrated acid into the inner lining of the reactor; use deionized water as a solvent, dissolve 0.46mol / L urea as a hydrolysis agent, add 0.01mol / L ammonium fluoride as a growth-directing agent, Cobalt ion salt and nickel ion salt are added under magnetic stirring, so that the element ratio of cobalt and nickel is 9 / 1. After mixing evenly, transfer it to the lining of the reactor to immerse the carbon felt, and keep it at 90 °C for hydrothermal reaction for 7 h; after cooling, wash the polyacrylonitrile carbon felt with deionized water, and dry it overnight at 7 °C to obtain layered cobalt-nickel hydroxide / Polyacrylonitrile carbon felt composite material, denoted as Co / Ni PAN-90.

Embodiment 2

[0039] Take the polyacrylonitrile carbon felt (PAN) acidified by concentrated acid into the inner lining of the reactor; use deionized water as a solvent, dissolve 0.46mol / L urea as a hydrolysis agent, add 0.01mol / L ammonium fluoride as a growth-directing agent, Cobalt ion salt and nickel ion salt are added under magnetic stirring, so that the element ratio of cobalt and nickel is 9 / 1. After mixing evenly, transfer it to the lining of the reactor to immerse the carbon felt, and keep it at 120 °C for hydrothermal reaction for 7 h; after cooling, wash the polyacrylonitrile carbon felt with deionized water and dry it at 70 °C overnight to obtain layered cobalt-nickel hydroxide / Polyacrylonitrile carbon felt composite material, denoted as Co / Ni PAN-120.

Embodiment 3

[0041] Take the polyacrylonitrile carbon felt (PAN) acidified by concentrated acid into the inner lining of the reactor; use deionized water as a solvent, dissolve 0.46mol / L urea as a hydrolysis agent, add 0.01mol / L ammonium fluoride as a growth-directing agent, Cobalt ion salt and nickel ion salt are added under magnetic stirring, so that the element ratio of cobalt and nickel is 9 / 1. After mixing evenly, transfer it to the lining of the reactor to immerse the carbon felt, and keep it at 180 °C for hydrothermal reaction for 7 h; after cooling, clean the polyacrylonitrile carbon felt with deionized water, and dry it at 70 °C overnight to obtain layered cobalt-nickel hydroxide / Polyacrylonitrile carbon felt composite material, denoted as Co / Ni PAN-180.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com