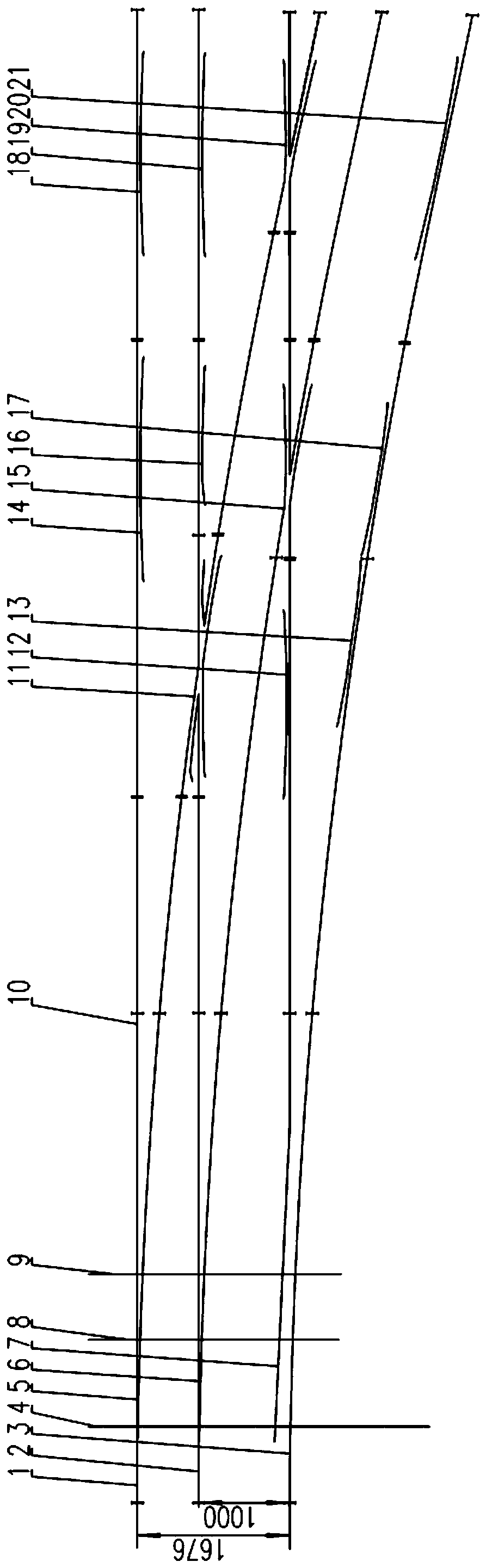

1676 mm and 1000 mm double-rail-distance mixed gage turnout

A technology for turnouts and grommets, which is applied in the field of double-gauge grommets, can solve the problems of no 1676mm wide gauge and 1000mm gauge gauges involving plans and other issues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A 1676mm and 1000mm double-gauge sleeve turnout, such as figure 1 As shown, it is mainly composed of a switch and a fixed frog; the switch includes three fixed basic rails and three linked switch rails.

[0014] The three basic rails are 1676mm straight-strand basic rail 1, 1000mm straight-strand basic rail 2 and common curved-strand basic rail 3, and the three point rails are 1676mm curved point rail 5, 1000mm curved point rail 6 and shared straight point Track 7. In this embodiment, the linkage mode of the three point rails is that each point rail is fixedly connected with multiple tie rods, and the multiple tie rods are arranged in parallel at intervals and perpendicular to the 1676mm straight stock basic rail and the 1000mm straight stock basic rail; two of the tie rods A power device is connected to provide power for pulling the switch rail.

[0015] The fixed frog is mainly composed of a two-way obtuse angle frog 11 arranged at the intersection of the 1000mm str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com