Grading evaluation method for explodability of step rock mass of open-pit mine rock

An evaluation method and technology of open-pit mines, applied in the field of open-pit mining, can solve the problems that it is difficult for a single index to comprehensively reflect the explosiveness, complexity, fuzziness and randomness of rock mass, and the reliability of classification results is low, so as to overcome the ambiguity Effects of sexual and random defects, high accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0108] Taking the East Open-pit Mine of China Coal Pingshuo Group Co., Ltd. as an example, due to the failure to accurately classify the explosiveness of the rock mass and the blasting design based on engineering experience, the average unit consumption of explosives and the blasting cost are high.

[0109] Through the scheme of the present invention, specifically as follows:

[0110] 1. Select the classification index of explosiveness of rock mass

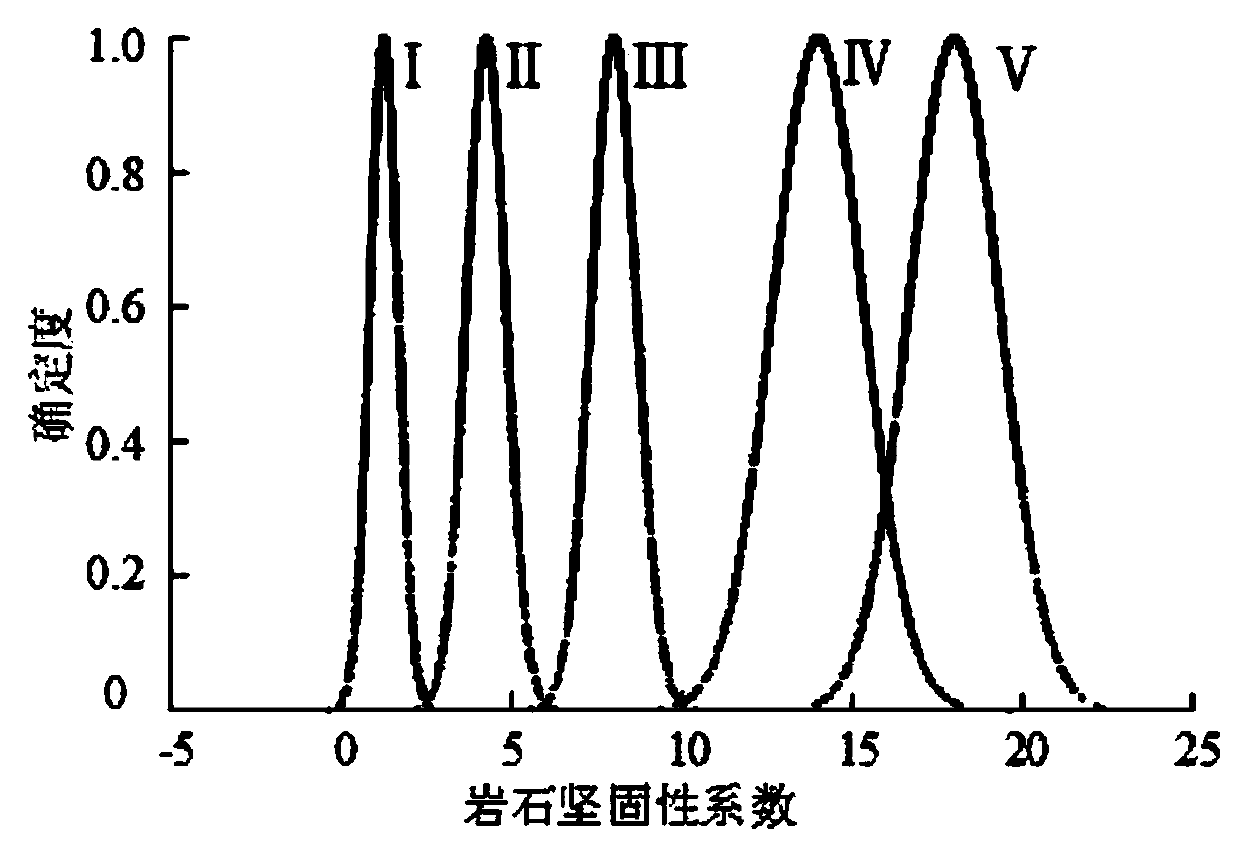

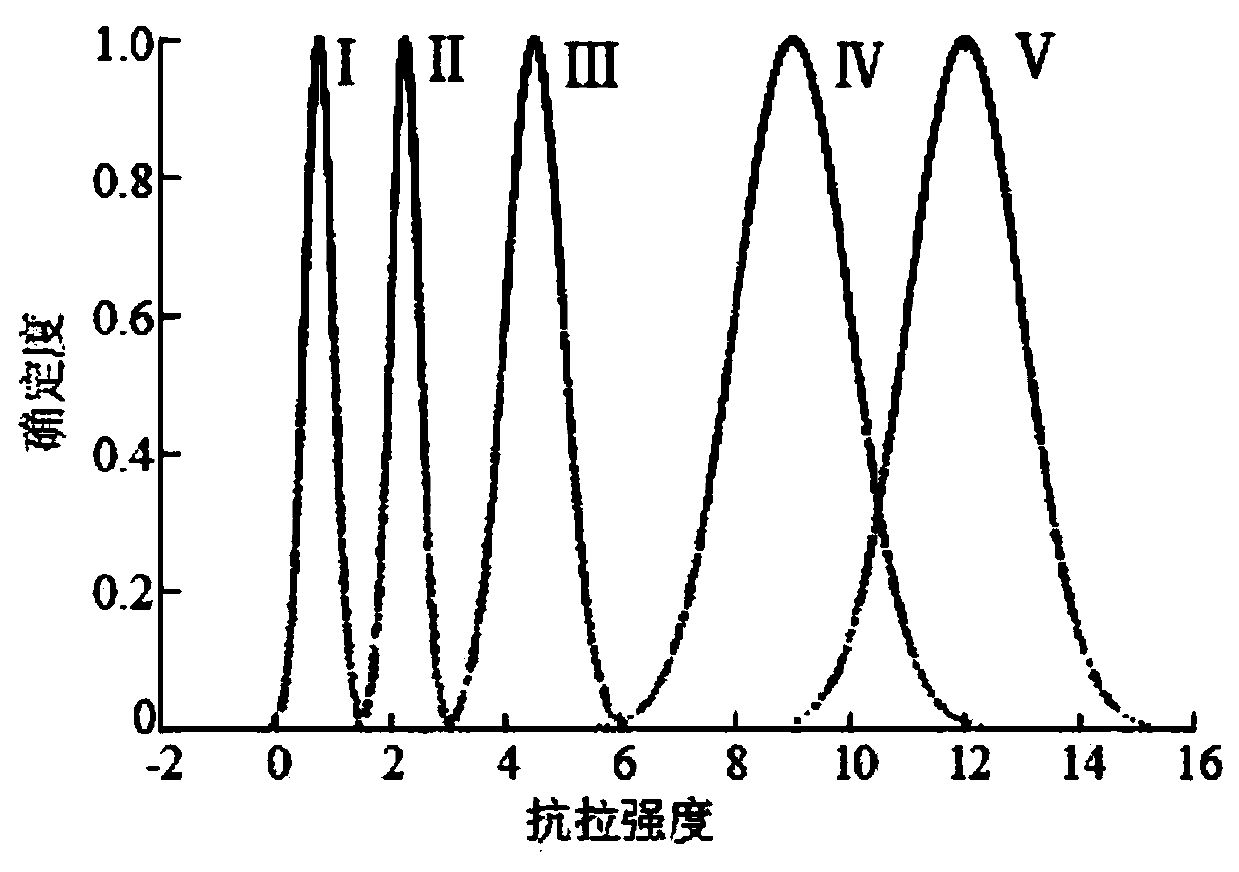

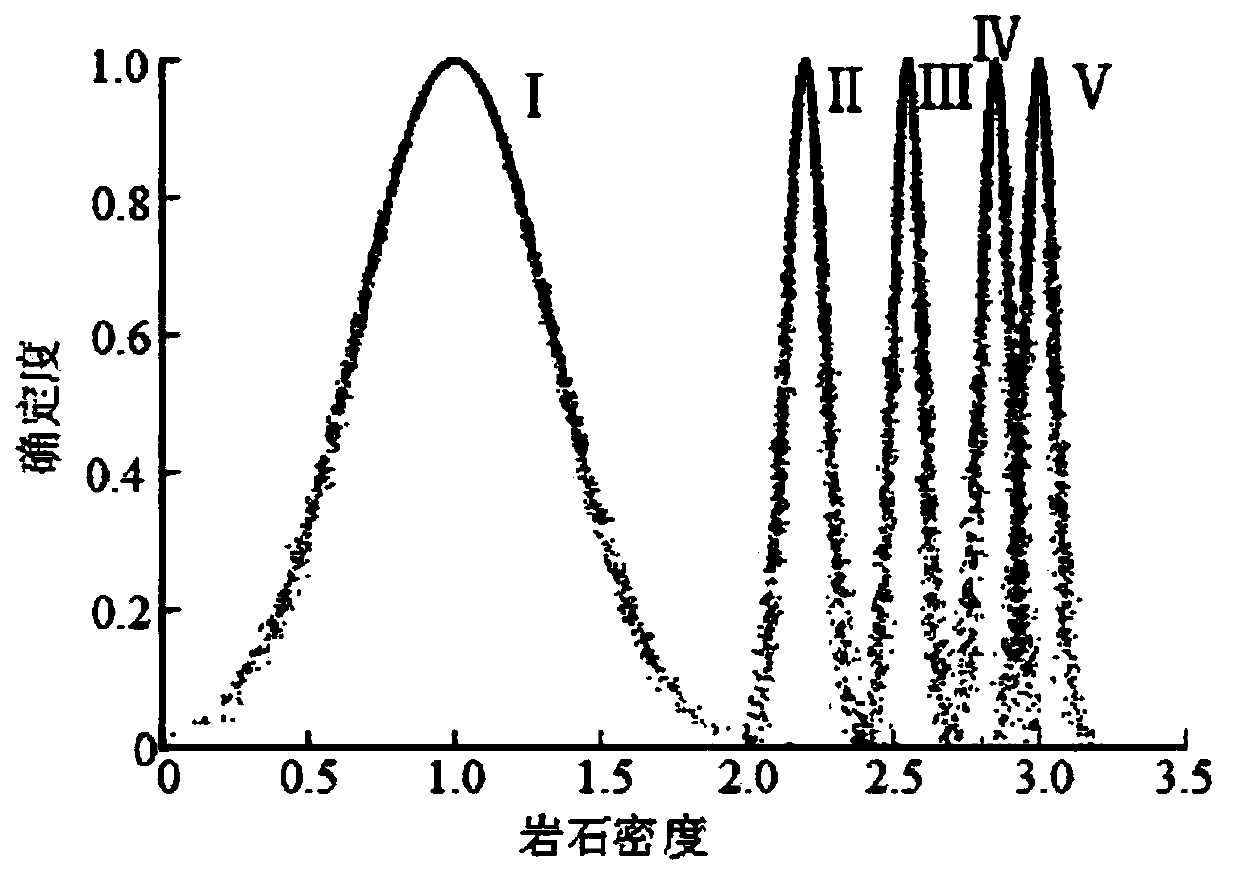

[0111] The five indexes of rock solidity coefficient, rock tensile strength, rock density, rock compressional wave velocity and rock mass compressional wave velocity are selected as the classification indexes of rock mass explosiveness.

[0112] 2. Determining the grading standard of explosiveness of rock formations

[0113] Referring to the grading standards of relevant literature, this application divides the explosiveness of rock mass into five grades: extremely explosive Ⅰ, explosive Ⅱ, moderate Ⅲ, difficult to explode Ⅳ and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com