Slip ring angle calibration method for intelligent MA transformation

A calibration method and technology of slip rings, which are applied in the fields of radiodiagnostic instruments, applications, medical science, etc., can solve the problem that the zero position of the slip ring and the actual zero position are accurately matched and difficult to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment the present invention is described in further detail.

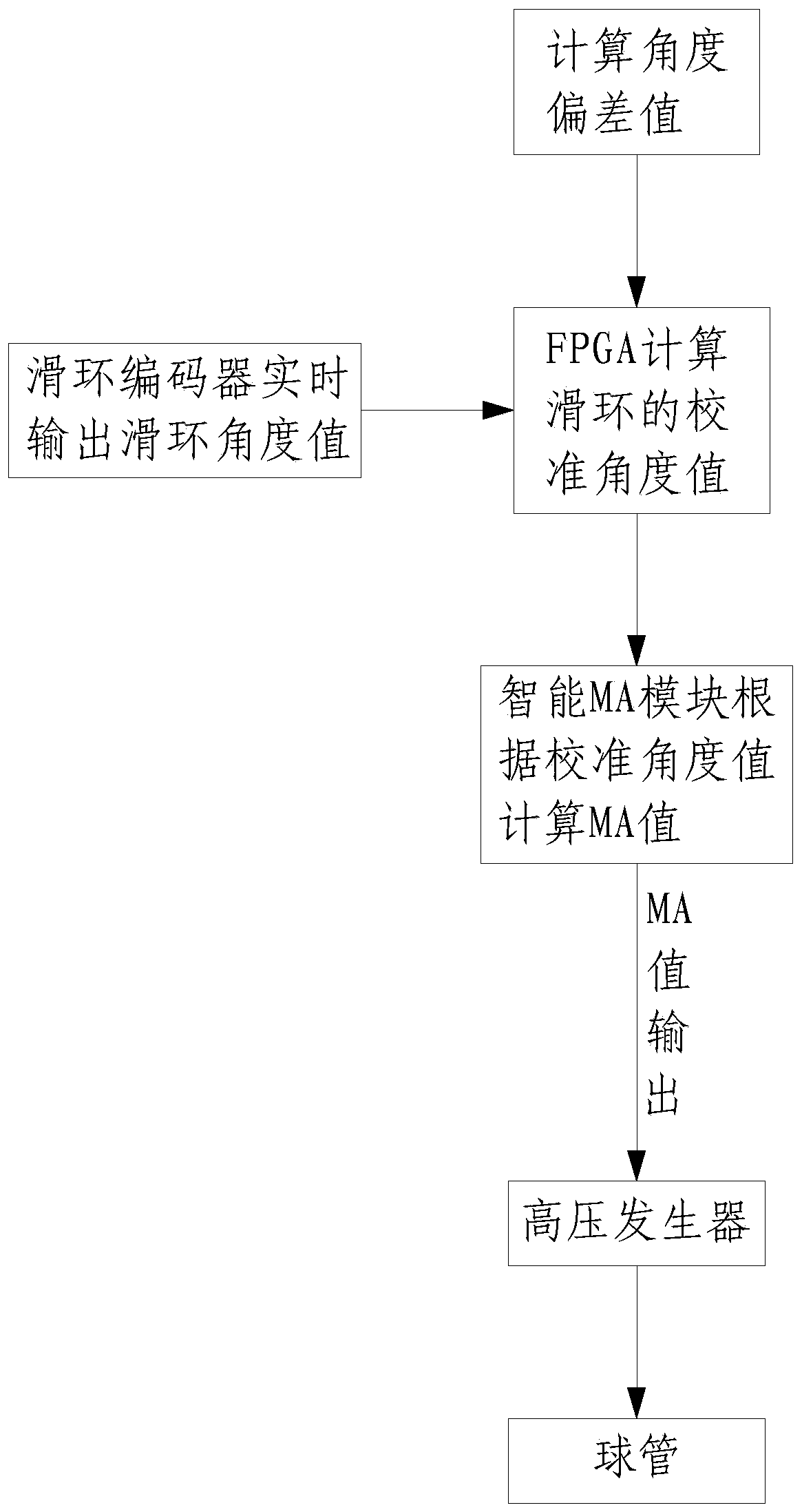

[0017] This embodiment proposes a slip ring angle calibration method for intelligent MA transformation, such as image 3 As shown, it includes slip ring encoder, FPGA, intelligent MA module, high voltage generator and bulb, where the output end of slip ring encoder is connected to the input end of FPGA, and the output end of FPGA is connected to the input end of intelligent MA module. The output end of the intelligent MA module is connected to the input end of the high-voltage generator, and the output end of the high-voltage generator is connected to the input end of the bulb, which is used to generate X-rays. The calibration method includes the following steps:

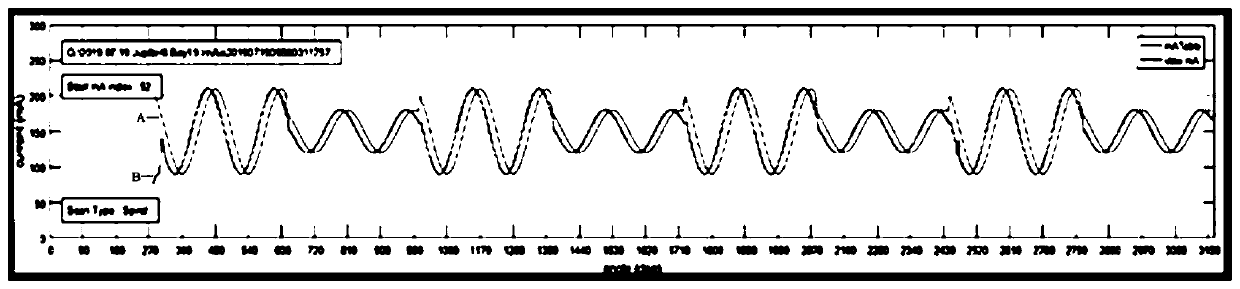

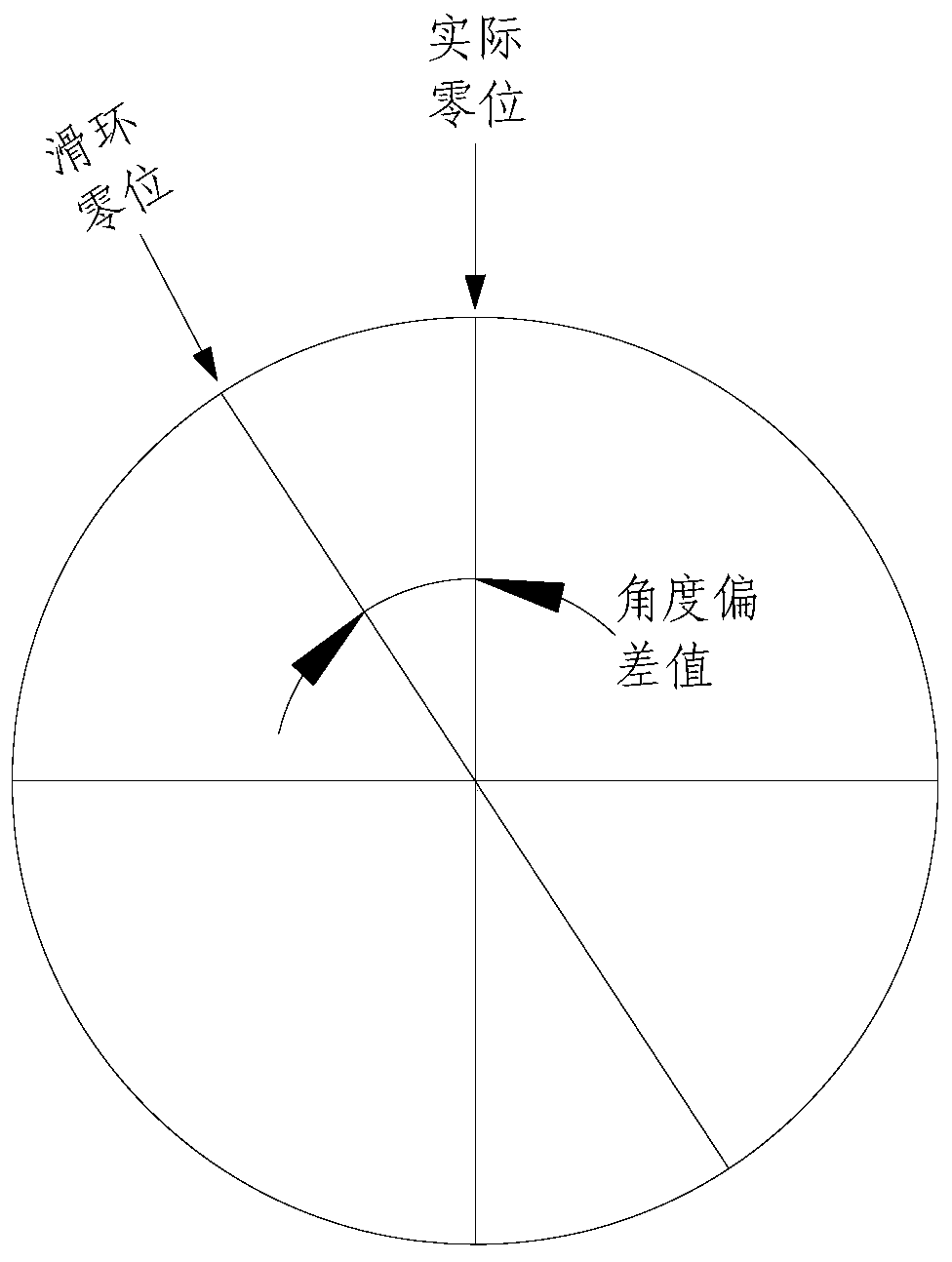

[0018] S01: Calculate the angle deviation value: Obtain the zero position of the slip ring through the slip ring encoder, and subtract the zero position of the slip ring from the actual zero position to form the angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com