Road construction and repairing device for tamping road after soil loosening

A repairing device and road construction technology, applied in road repair, roads, roads, etc., can solve problems such as inconvenience of use and inability to adjust the coverage width, and achieve the effect of convenient movement and adjustable coverage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

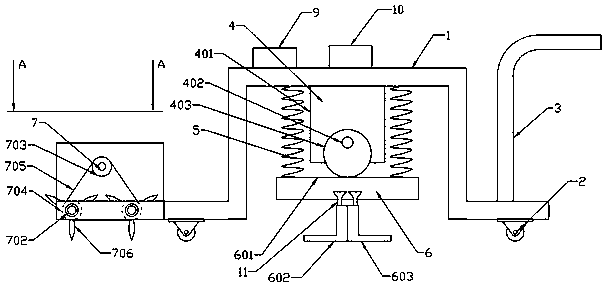

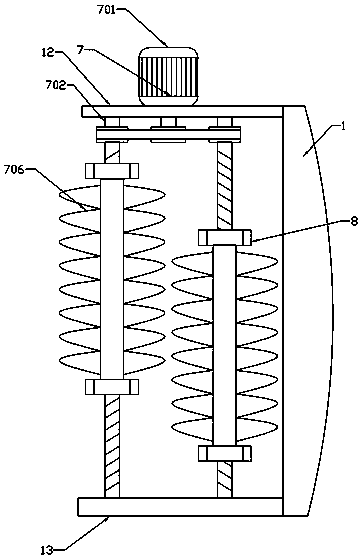

[0021] see Figure 1~3 , in an embodiment of the present invention, a device for road construction and finishing after loosening soil and compacting it includes a mounting frame 1 whose appearance is in the shape of a "several" shape, and a first Riser 12, a second riser 13 is installed on the left end lower side of the mounting frame 1, and a loosening mechanism 7 is installed between the first riser 12 and the second riser 13, and the loosening mechanism 7 includes: Second motor 701, screw rod 702, driving wheel 703, driven wheel 704, transmission belt 705 and ripper 706, described second motor 701 is installed on the second vertical plate 13, and the output shaft of described second motor 701 is installed with The driving wheel 703, a screw 702 is symmetrically installed on the left and right sides below the second motor 701, and a ripper 706 is respectively installed on the two screw 702, and a ripper 706 for fixing the ripper 706 is installed on the screw 702. Self-locki...

Embodiment 2

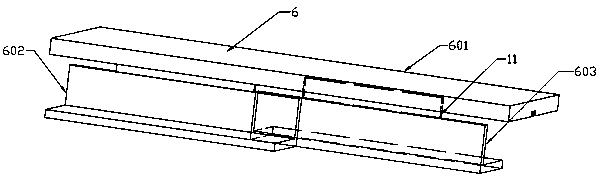

[0023] see Figure 1~3 , in the embodiment of the present invention, the tamping device 6 includes: a lifting plate 601, a first tamping device 602 and a second tamping device 603, the bottom of the lifting plate 601 is equipped with a first tamping device 602, and the first tamping device 602 A second tamper 603 is installed on the right side of the device 602 at the bottom of the lifting plate 601 , and the first tamping device 602 and the second tamping device 603 are slidably connected to the lifting plate 601 through a T-shaped slider 11 respectively.

[0024] The road construction finishing device tamped after loosening the soil, drives the eccentric roller 403 to rotate through the rotation of the first motor 402, drives the lifting plate 601 to move up and down through the rotation of the eccentric roller 403, and drives the first compactor 602 and The second tamper 603 moves up and down, and by adjusting the relative position of the first tamper 602 and the second tam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com