Vehicle pillar structure

一种结构体、支柱的技术,应用在上部结构、车辆部件、上部结构分总成等方向,能够解决妨碍填充材料流动、填充材料填充状态不稳定等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

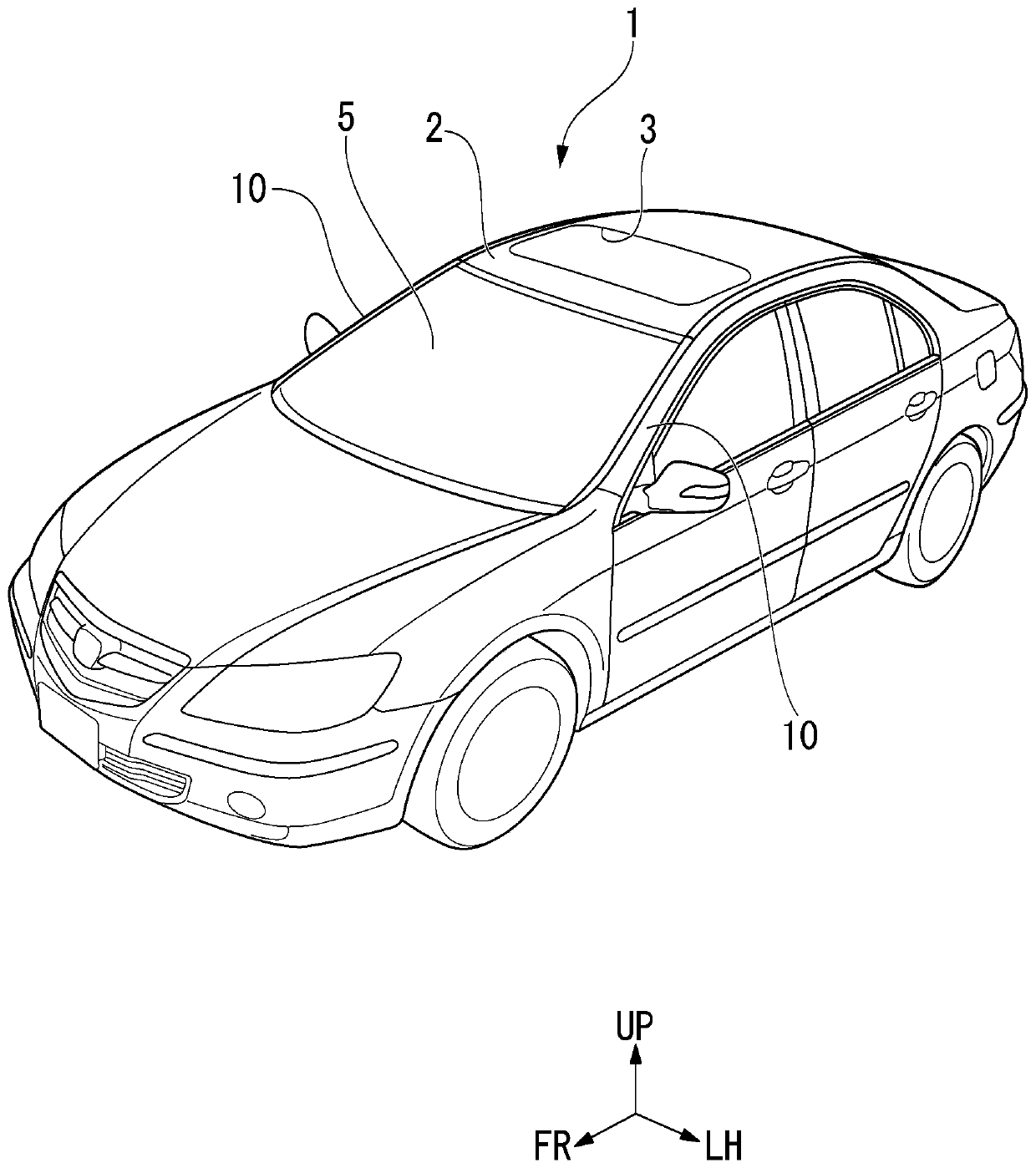

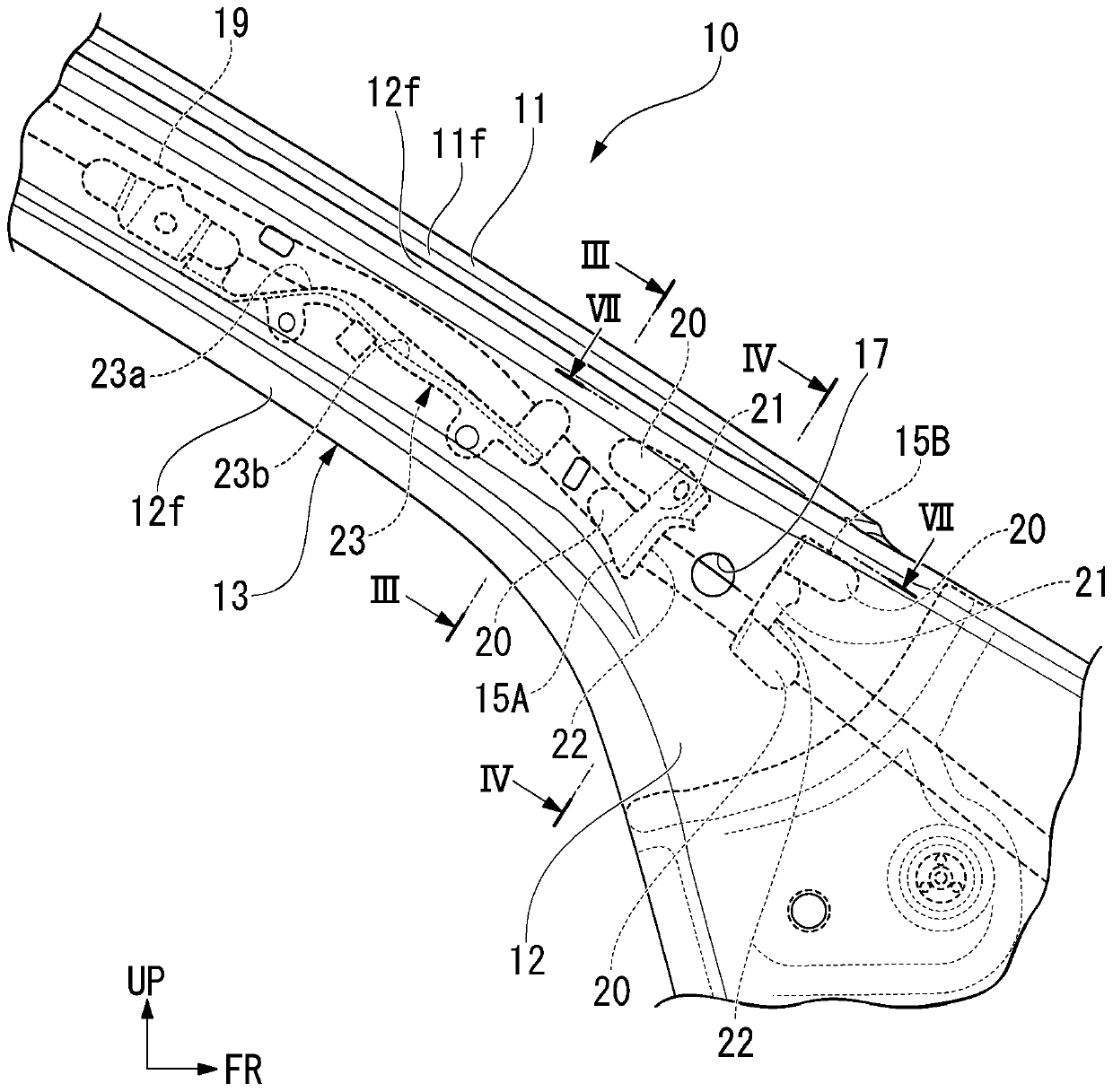

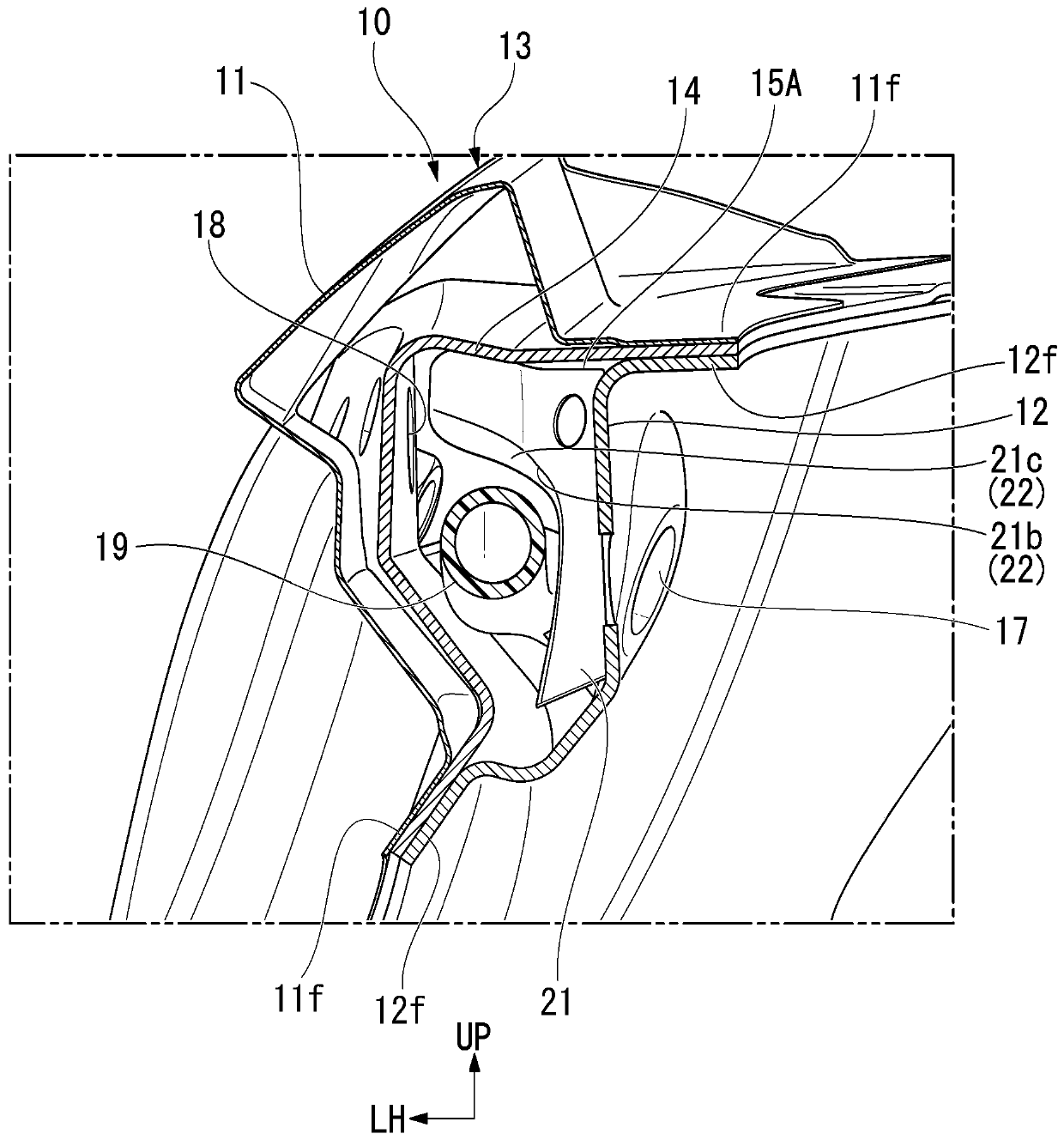

[0037] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, in the following description, front-back, top-bottom, and left-right refer to the front-back, top-bottom, and left-right of a vehicle unless otherwise specified. In addition, arrow FR in the figure indicates the front of the vehicle, arrow UP indicates the upper side of the vehicle, and arrow LH indicates the left side of the vehicle.

[0038] figure 1 It is a diagram when the vehicle 1 employing the pillar structure of the present embodiment is viewed obliquely from the upper left at the front.

[0039] Front pillars 10 extending obliquely upward from the side lower end of the windshield glass 5 toward the roof 2 are provided on both left and right sides of the front of the cabin of the vehicle 1 . The pillar structure of this embodiment is used for the front pillar 10 . However, the pillar structure of the present embodiment can also be used for rear pil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com