No show socks without glue dispensing and free from dropping, and weaving technology

A technology of invisible socks and craftsmanship, applied in socks, pantyhose, apparel and other directions, can solve the problems of prolonged product production cycle, cumbersome, low process efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

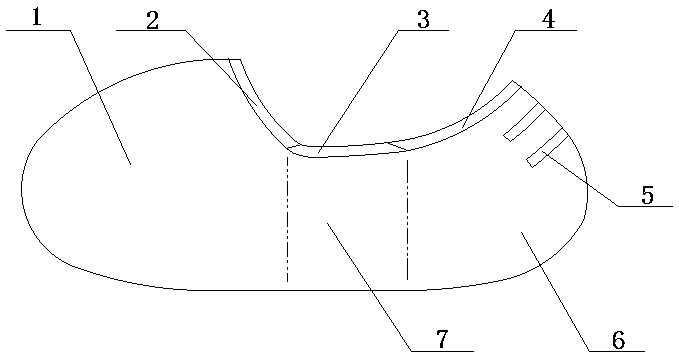

[0035] Embodiment 1: as image 3 As shown, a invisible sock knitting process that does not need to be glued and does not fall off, adopts the following steps to knit: toe rib knitting section » sock toe knitting section » side knitting section » side rib knitting section » sock heel knitting section » Sock heel cuff knitting section.

Embodiment 2

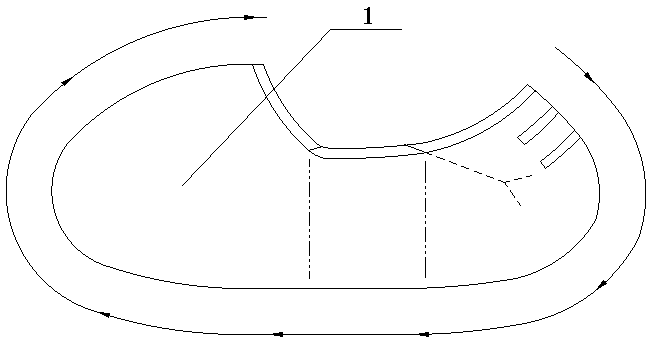

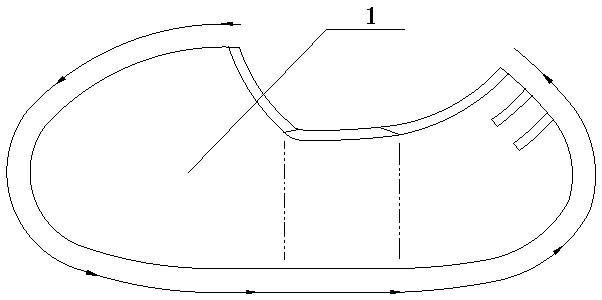

[0036] Embodiment 2: as figure 2 As shown, a invisible sock knitting process that does not need to be glued and does not fall off, adopts the following steps to knit: socks heel knitting section » heel knitting section » side knitting section » side cuff knitting section » toe knitting section » Knitting section of cuff cuff.

Embodiment 3

[0037] Embodiment 3: as figure 2As shown, a invisible sock knitting process that does not need to be glued and does not fall off, adopts the following steps to knit: sock heel cuff knitting section » heel knitting section » side knitting section and side cuff knitting section » toe knitting section » Knitting section of cuff cuff. The side knitting section and the side cuff knitting section adopt the technical means of synchronous knitting to increase the side elasticity and improve the wearing comfort of the invisible socks. The side edge and the side cuff of the invisible socks of the present invention can realize low-efficiency alternate synchronous knitting through single-way shuttle change. The side edge and the side cuff of the invisible socks of the present invention can also realize high-efficiency synchronous weaving through multi-way participating in weaving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com