Wood pulp crushing equipment with double wood pulp rolls capable of performing automatic feeding

A technology of automatic feeding and crushing equipment, applied in the directions of fiber raw material, raw material separation, fiber raw material processing, etc., can solve the problems of wood pulp rolls that are difficult to ensure after feeding, and achieve the effect of simple feeding structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

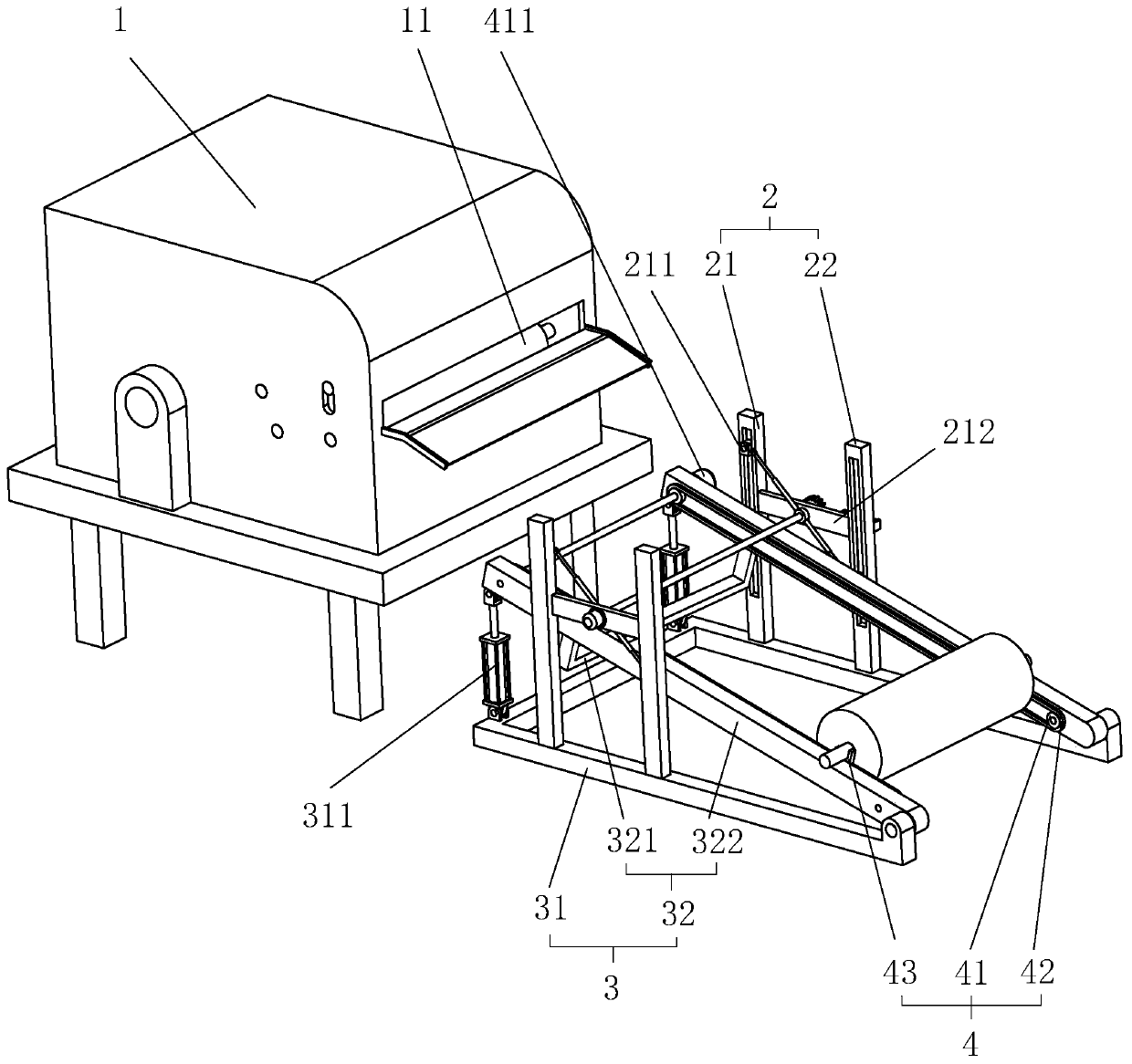

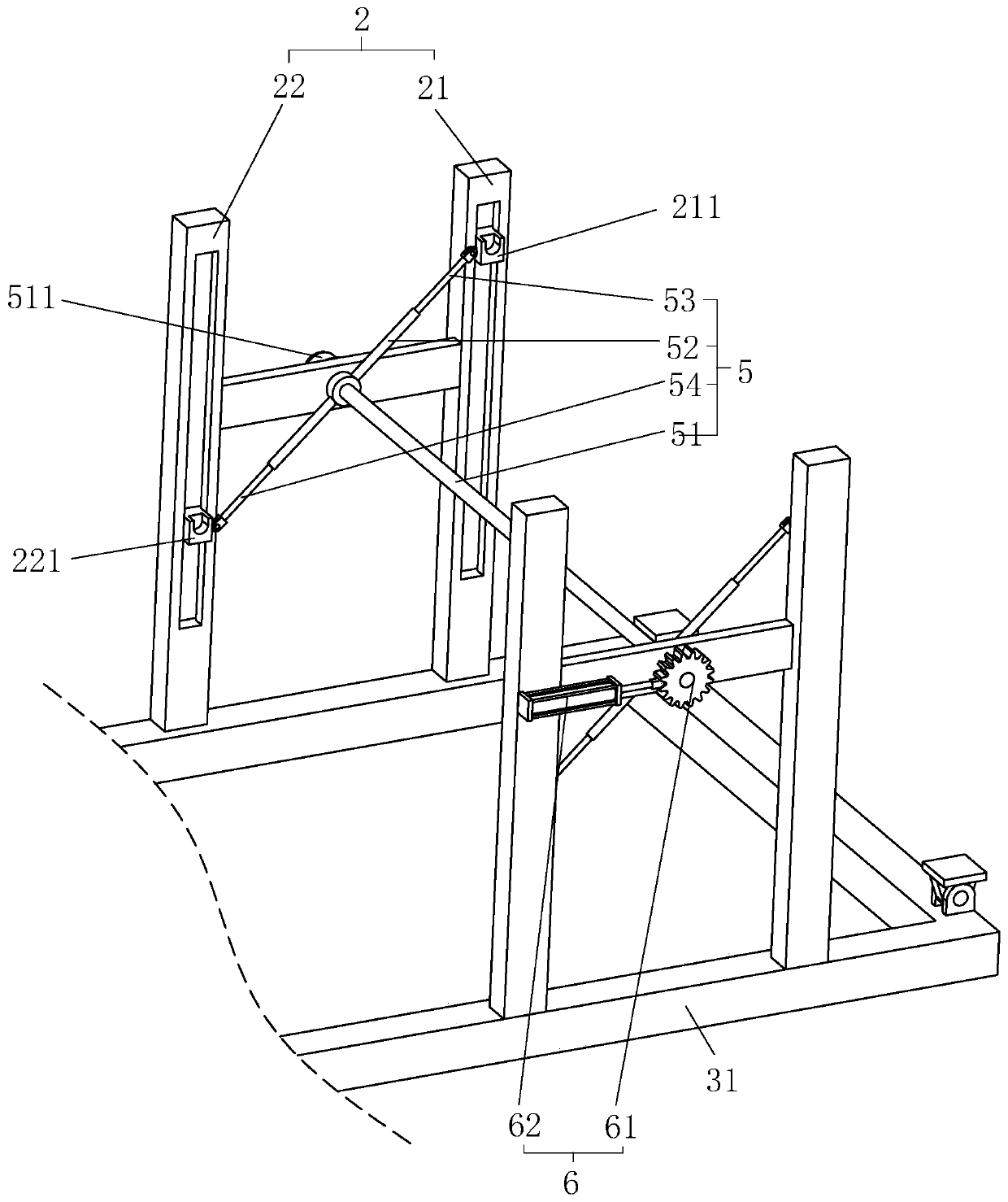

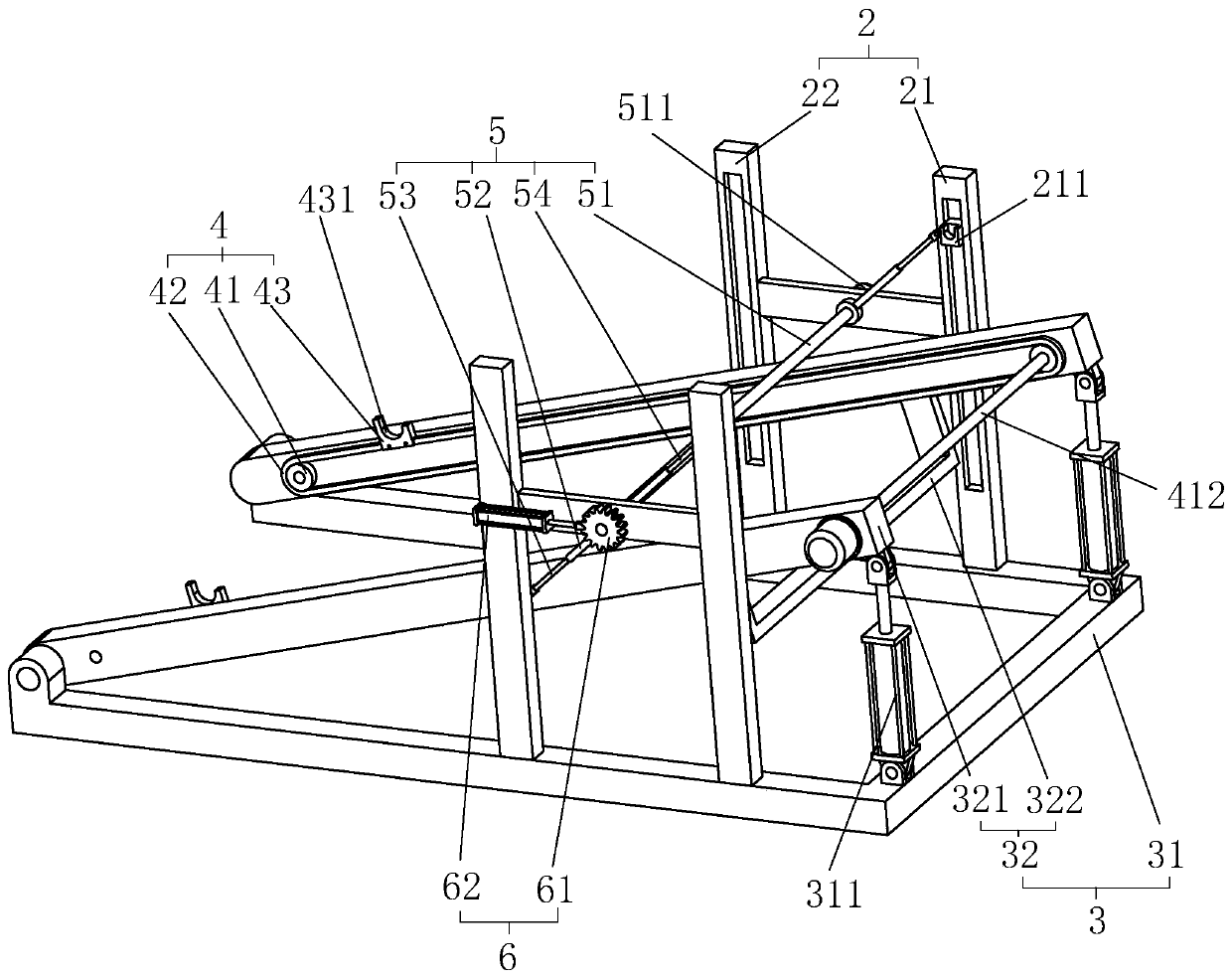

[0031] refer to figure 1 and figure 2, which is a kind of wood pulp pulverizing equipment with automatic feeding of double wood pulp rolls disclosed by the present invention, comprising a frame 1, the frame 1 is provided with an automatic wood pulp splicing device 11, the frame 1 is provided with a feeding device 2, and the feeding device 2 is arranged on the frame 1 The device 2 includes a first bracket 21 and a second bracket 22 that are parallel to each other and gradually move away from the frame 1. The opposite side of the first bracket 21 is vertically slidably connected to a first axle support 211, and the opposite side of the second bracket 22 is vertically slidably connected to a The second shaft support 221, the first shaft support 211 and the second shaft support 221 are all placed with a wood pulp roll, and the two ends of the wood pulp shaft of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com