Automatic powder weighing machine material conveying device with vibrator

A vibrator, electromagnetic vibrator technology, applied in measurement devices, transportation and packaging, weighing equipment for materials with special properties/forms, etc., can solve the problems of complex structure, high cost, inability to convert products, etc. The effect of simple material structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

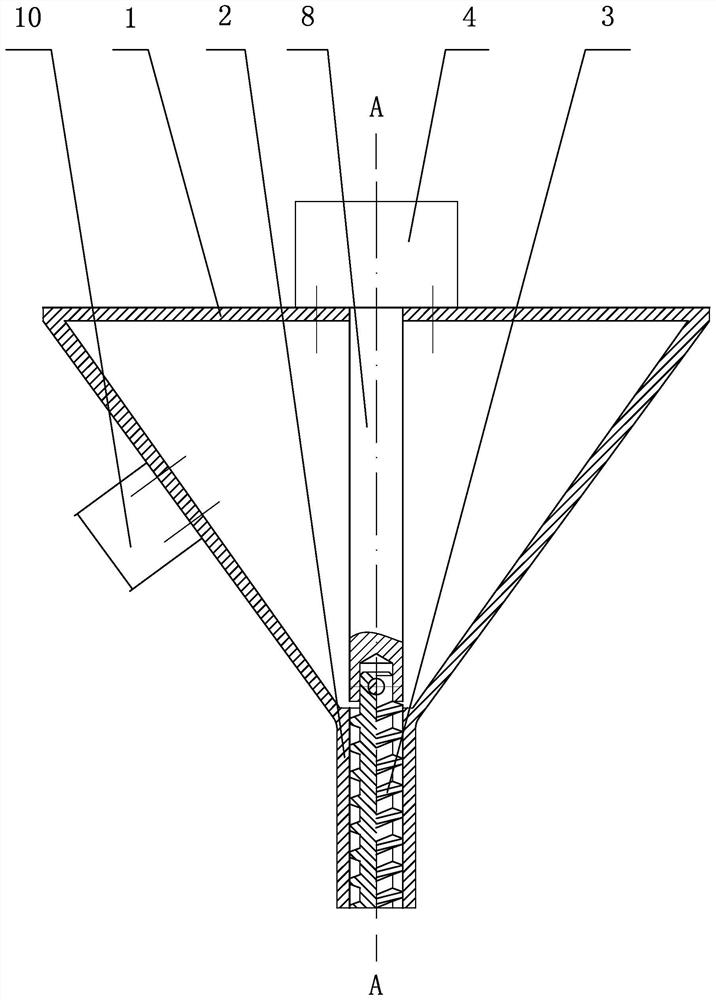

[0035] The conveying pipe 2 (vertical shape) is coaxially installed on the outlet of the bucket-shaped box, and the upper end shaft head of the screw feeding rod 3 is coaxially embedded in the long axis 8 (coaxially arranged in the bucket-shaped box) The shaft hole at the bottom is provided with a threaded pin hole on the long axis 8 corresponding to the shaft hole, and a threaded pin is screwed in the threaded pin hole to lock the screw feed rod 3 on the long shaft 8, as figure 1 shown.

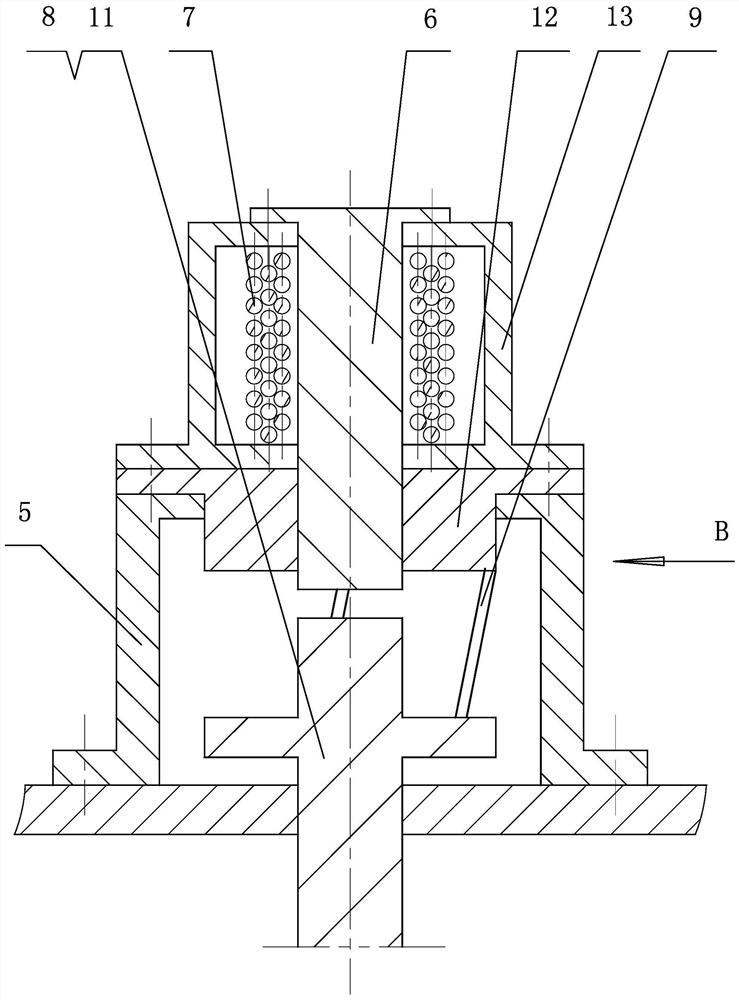

[0036] The power mechanism includes an electromagnetic vibrator I4 coaxially installed on the case cover through an electromagnetic seat 5, and the electromagnetic vibrator I4 includes a shell seat 13 coaxially installed on the electromagnetic seat 5 through a spring seat 12, and the shell seat 13 is provided with an electromagnetic shaft 6 that coaxially passes through the center hole of the spring seat 12 and is placed in the electromagnetic seat 5. The shell seat 13 is also provided with ...

Embodiment 2

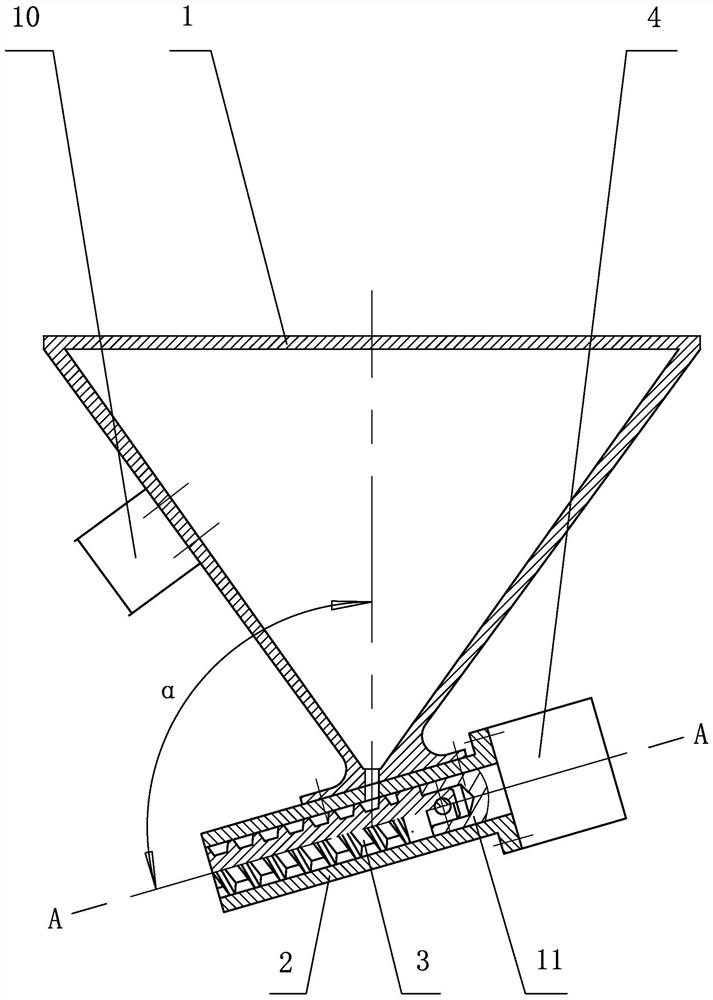

[0043] The axis of the conveying pipe 2 forms an angle with the vertical axis of the storage box 1, that is, it is obliquely installed on the bottom of the lower opening of the bucket-shaped box (the angle of inclination α is preferably 30°-60° and 120°-180°, When α=180°, it is Embodiment 1), the oblique upper end shaft head of the screw feeding rod 3 is coaxially embedded in the short shaft 11 (coaxially arranged in the pipe body on the oblique upper part of the delivery pipe 2, and the oblique upper end of the delivery pipe 2 The shaft hole at the bottom of the lower end nozzle is the discharge port), corresponding to the shaft hole, a threaded pin hole is provided on the short shaft 11, and a threaded pin is screwed in the threaded pin hole to lock the screw feed rod 3 on the short shaft 11, such as figure 2 shown.

[0044]The power mechanism includes an electromagnetic vibrator I4 coaxially installed on the pipe cover (set on the nozzle at the oblique upper end of the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com