Optimised tunnel ventilation device

A ventilation flow and fan technology, applied in mine/tunnel ventilation, pump devices, parts of pumping devices for elastic fluids, etc., can solve problems such as pressure loss, reduce power consumption, avoid flow separation, Create simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

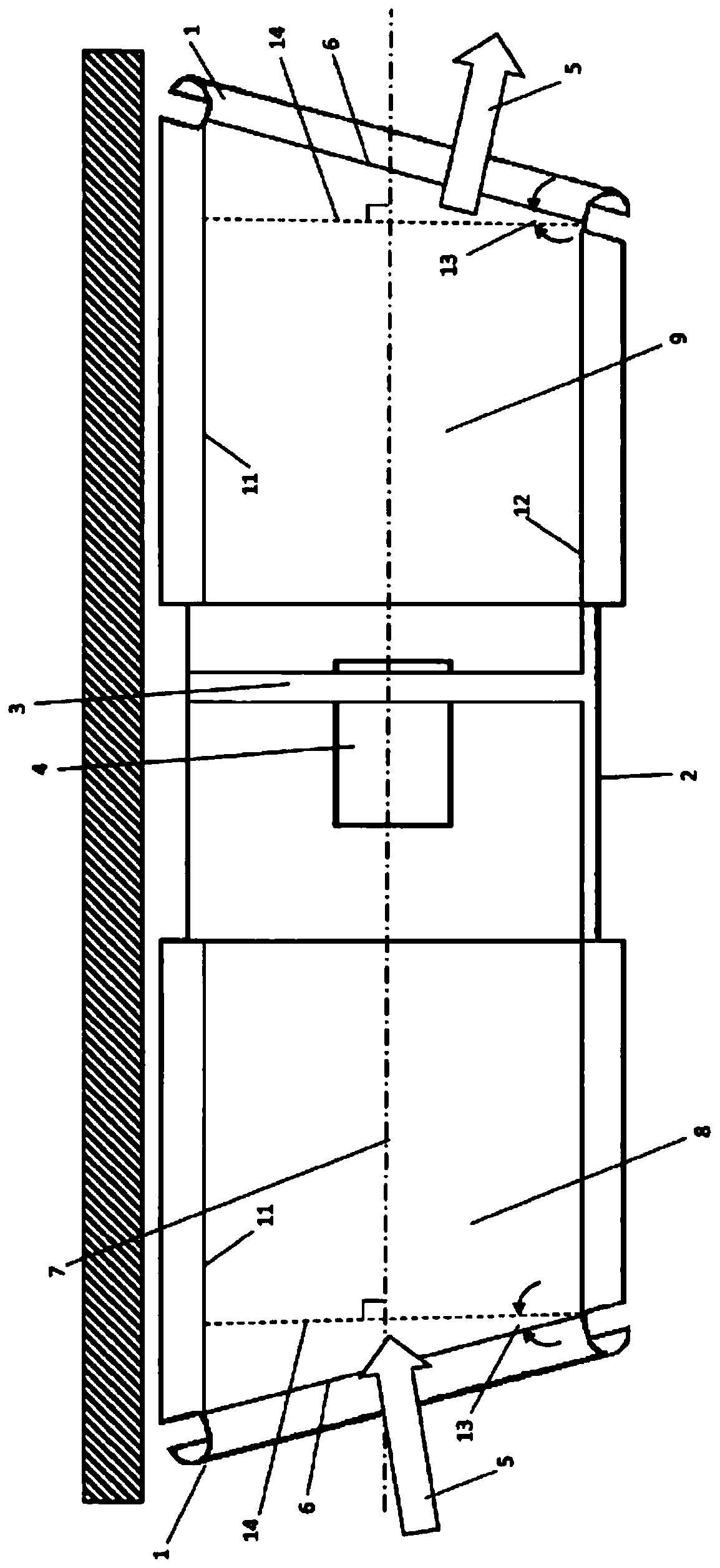

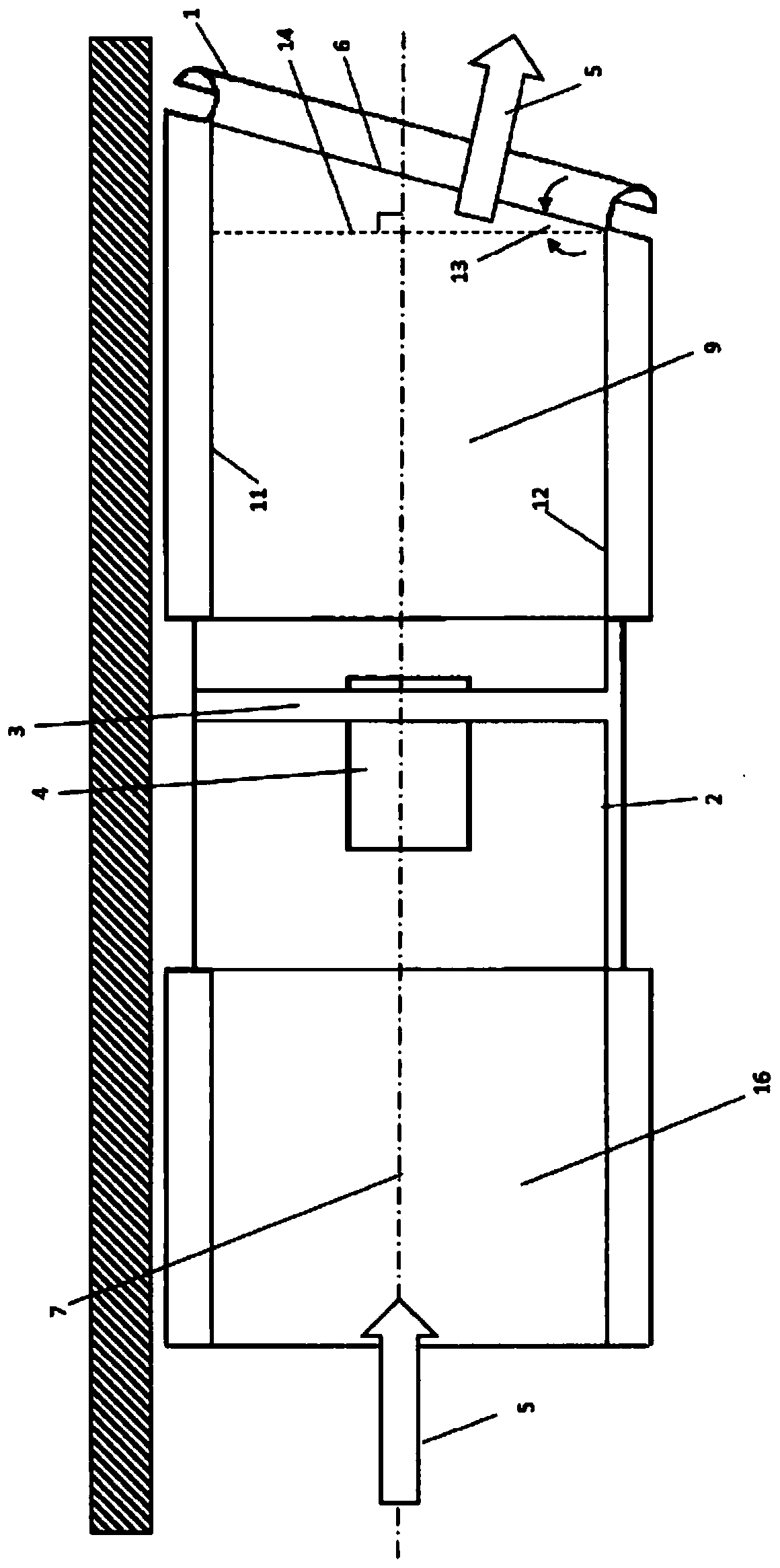

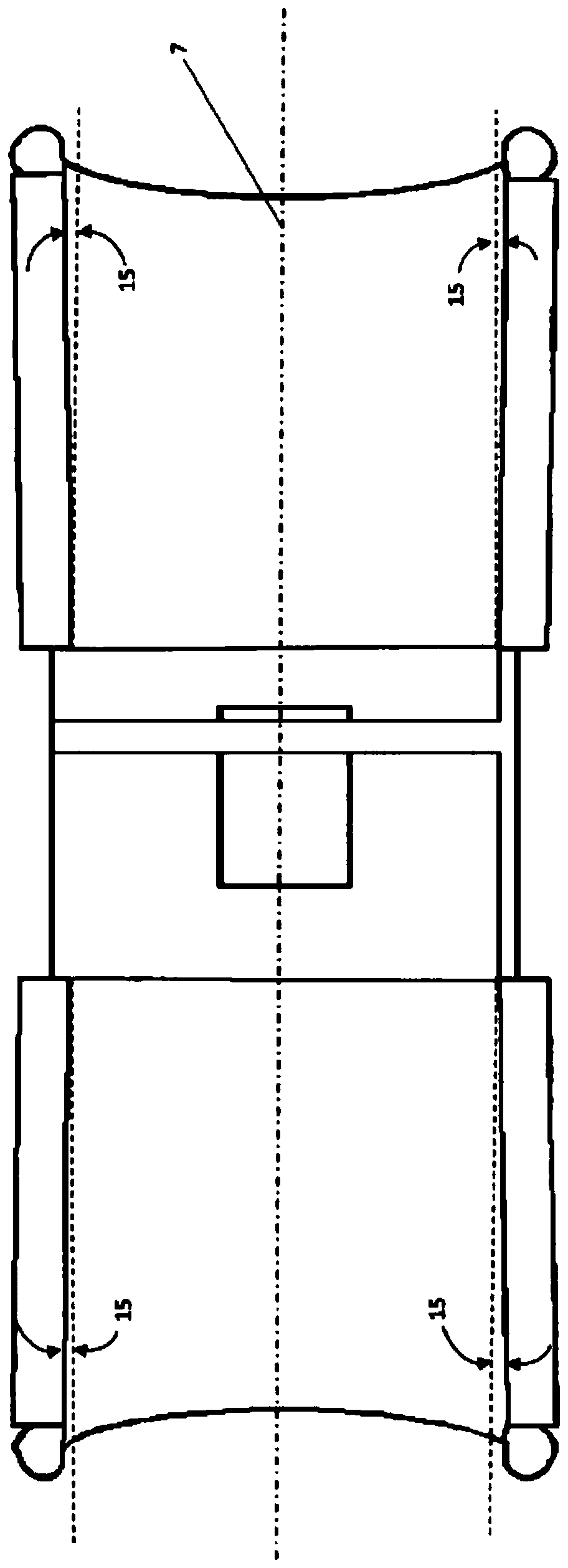

[0049] refer to figure 1 , figure 1 Shown is a cross-sectional side view of an embodiment of the present invention installed within a two-way ventilation device under a tunnel soffit, the two-way ventilation device being designed to operate in a fully reversible manner.

[0050] In this embodiment, a fan assembly including a fan rotor (3) driven by a motor (4) is mounted within the fan housing (2). The fan rotor (3) is installed along the centerline (7) of the fan.

[0051] The airflow (5) enters the fan rotor (3) through the bell mouth (1) and the inlet nozzle through hole (8), and then is discharged through the outlet nozzle through hole (9) and the bell mouth (1). The inlet and outlet trailing edges of the nozzle (6) are inclined at an angle (13) relative to the normal to the centerline (7) of the fan. The exhaust air flow is deflected by the upper surface of the bell mouth (1) in a direction away from the tunnel surface, thus reducing the Coanda effect.

[0052] Prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com