Lens device and method for manufacturing lens device

A lens and lens body technology, applied in installation, telescope, optics, etc., can solve the problems of small size, system tube manufacturing cost, expensive, etc., and achieve the effect of cheap manufacturing, saving manufacturing cost, and efficient layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

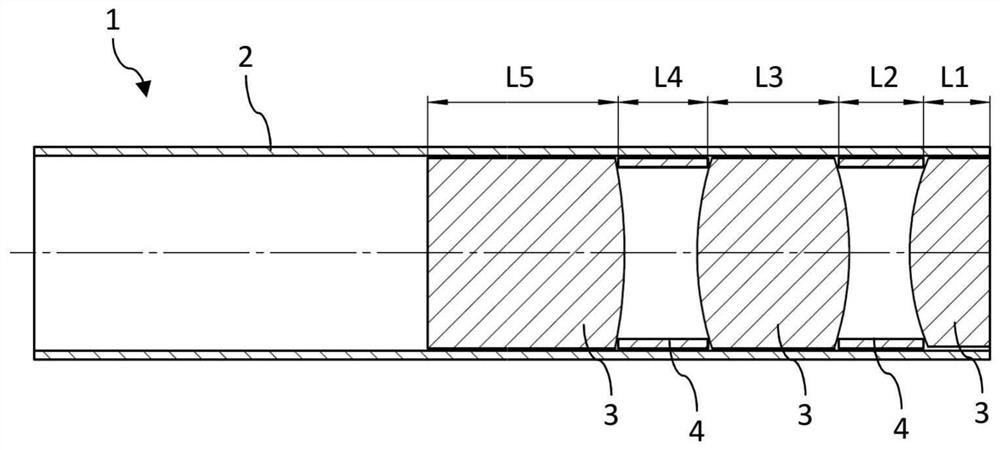

[0063] FIG. 1 shows a lens arrangement 1 according to the prior art. The lens arrangement 1 has an optics carrier 2 , which is designed here as a system tube. The optics carrier 2 is of tubular design. Three lenses 3 are arranged in the optics carrier 2 , wherein in each case a spacer ring 4 is arranged between the lenses 3 , around which spacer rings the axial position of the lenses 3 is defined. In this case, a rod lens is formed by way of example as lens 3 , but the invention is suitable for all lens forms without exception.

[0064] The position of the third lens 3 is obtained, for example, by adding the dimensions L1 to L4. From this it is clear that tolerances in the lengths of the spacer ring 4 and of the lens 3 accumulate. It is therefore almost impossible to determine the absolute position of the lens. This causes aberrations.

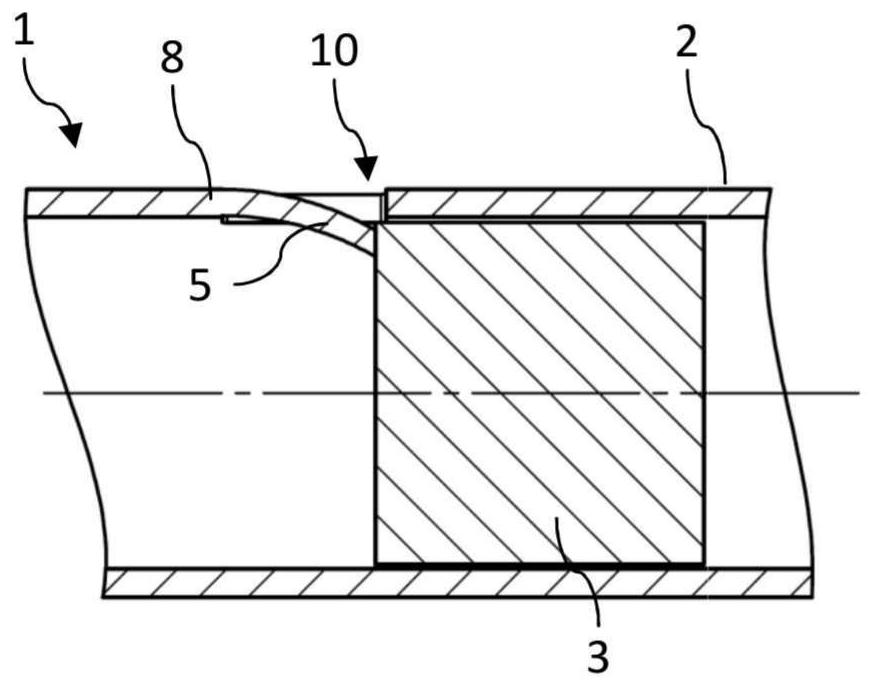

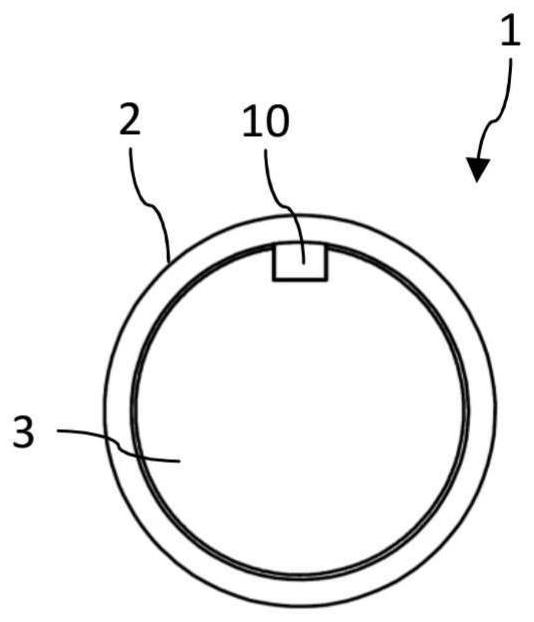

[0065] Also in the following embodiments, the lenses 3 are respectively shown as rod lenses. However, the invention is not limited to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com