Preparation method of slender metal material tensile sample

A technique for tensile specimens and metal materials, applied in the field of preparation of slender metallic material tensile specimens, can solve problems such as size control, and achieve the effects of convenient operation, solving difficulty in controlling the size of samples, and a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

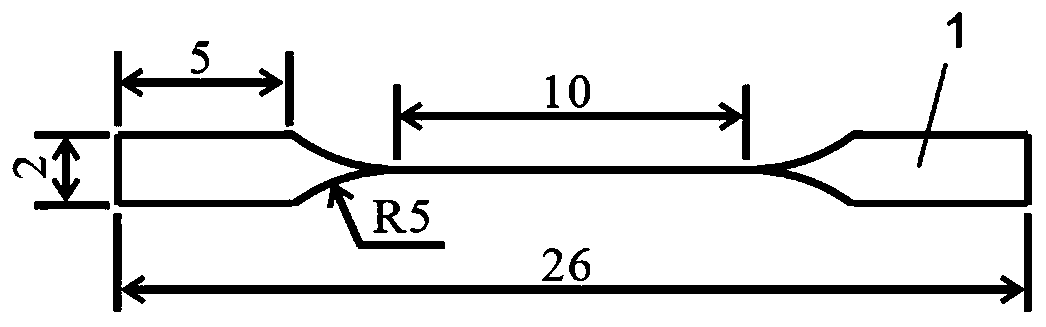

[0039] The invention relates to a method for preparing an elongated metal material tensile sample, and the target sample gauge section size is: 10 millimeters in length, 40 microns in width, and 40 microns in thickness.

[0040] Concrete preparation process is as follows:

[0041] (1) The initial sample is processed by wire electric discharge cutting equipment, and the cross section of the initial sample is square. The material of sample 1 is maraging steel; each surface is polished with sandpaper to remove wire cutting marks; in order to achieve an ideal surface state, the model of sandpaper is recommended to be No. 1200.

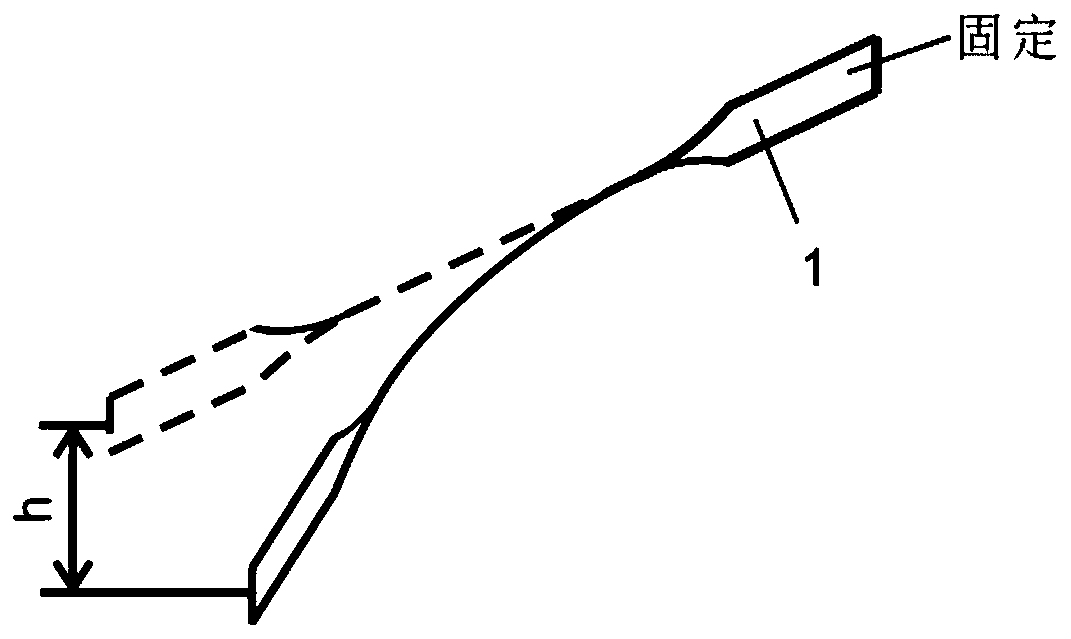

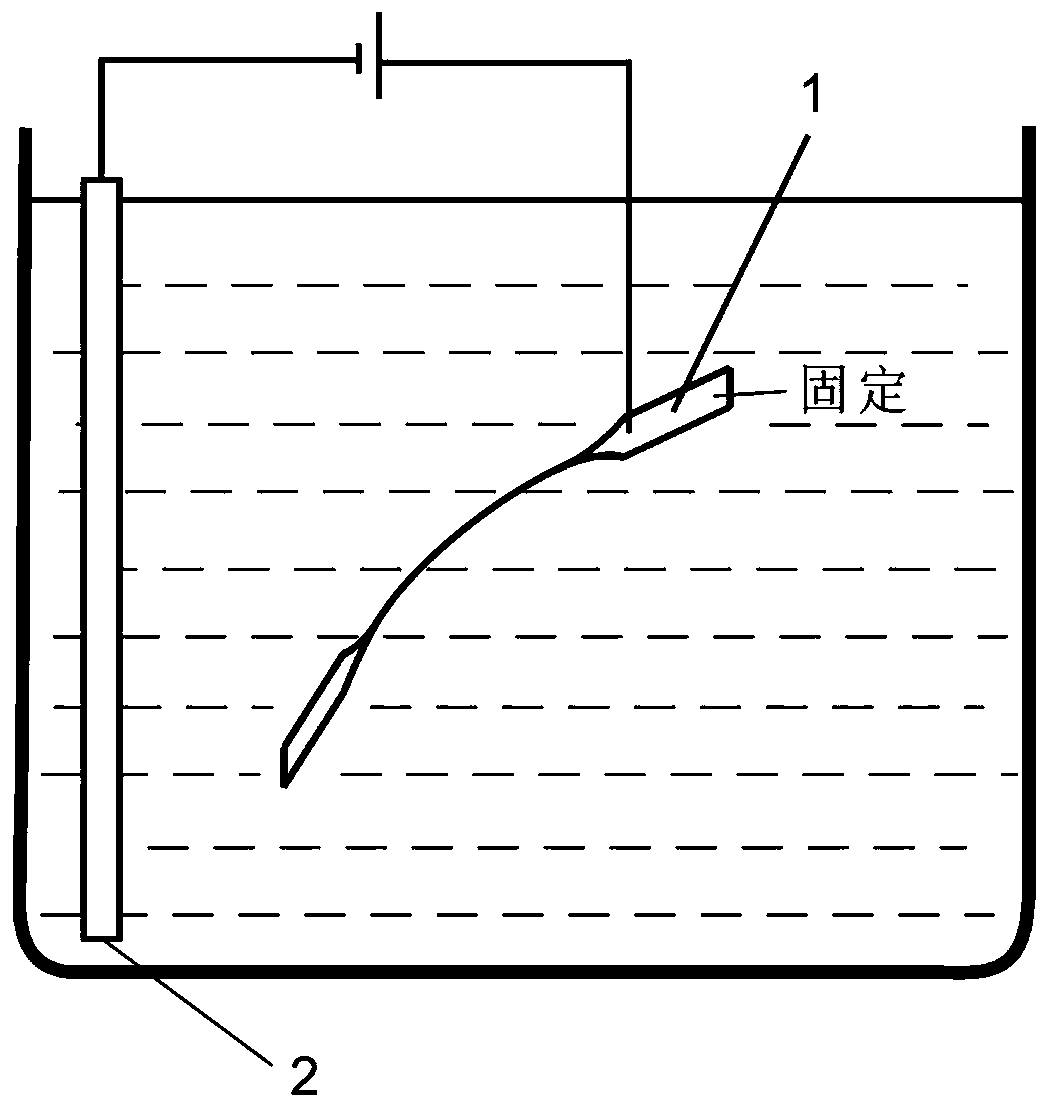

[0042] (2) According to the target size of the sample ( figure 1 ) and the density of the material to calculate the sample’s drop height h at the end of the free clamping end of the sample when the inclination angle is θ; in order to achieve the ideal observation effect, the inclination angle is selected to be 60° ( figure 2 ).

[0043] The calculation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com