Centrifugal impeller and blowing and inducing device comprising same

A centrifugal and impeller technology, which is applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve the problem of the installation angle destroying the uniform arrangement of the circumferential angle of the blades and affecting the efficiency of the impeller , large vibration and noise, etc., to achieve the effect of improving air outlet efficiency, improving air outlet efficiency, and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The disclosure of the present invention discloses a blowing device. In this embodiment, the blowing device is an AC blowing machine. Of course, the blowing device can also be a blower, and the power source of the blowing device can also be a gasoline engine or a DC battery. Bag.

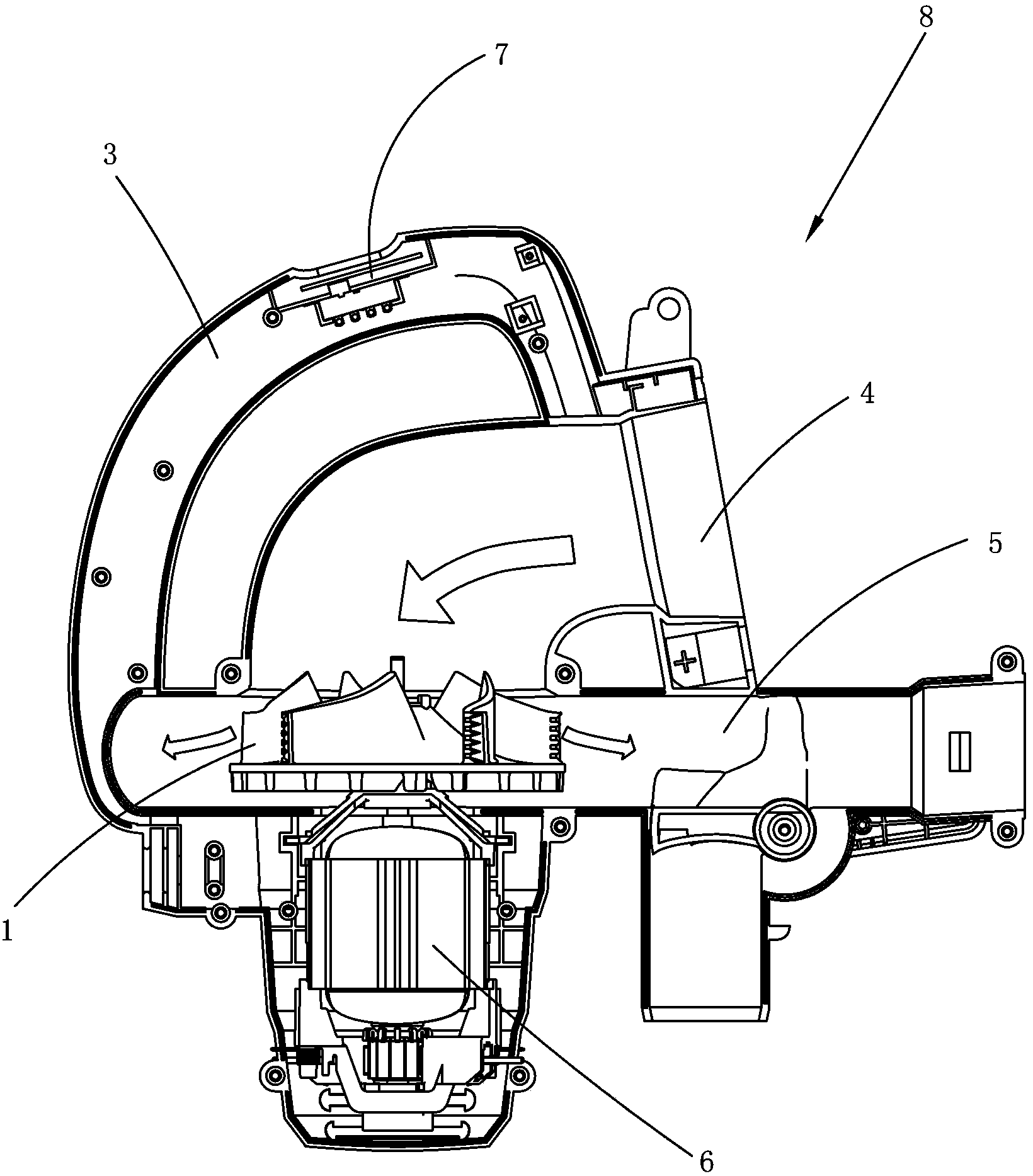

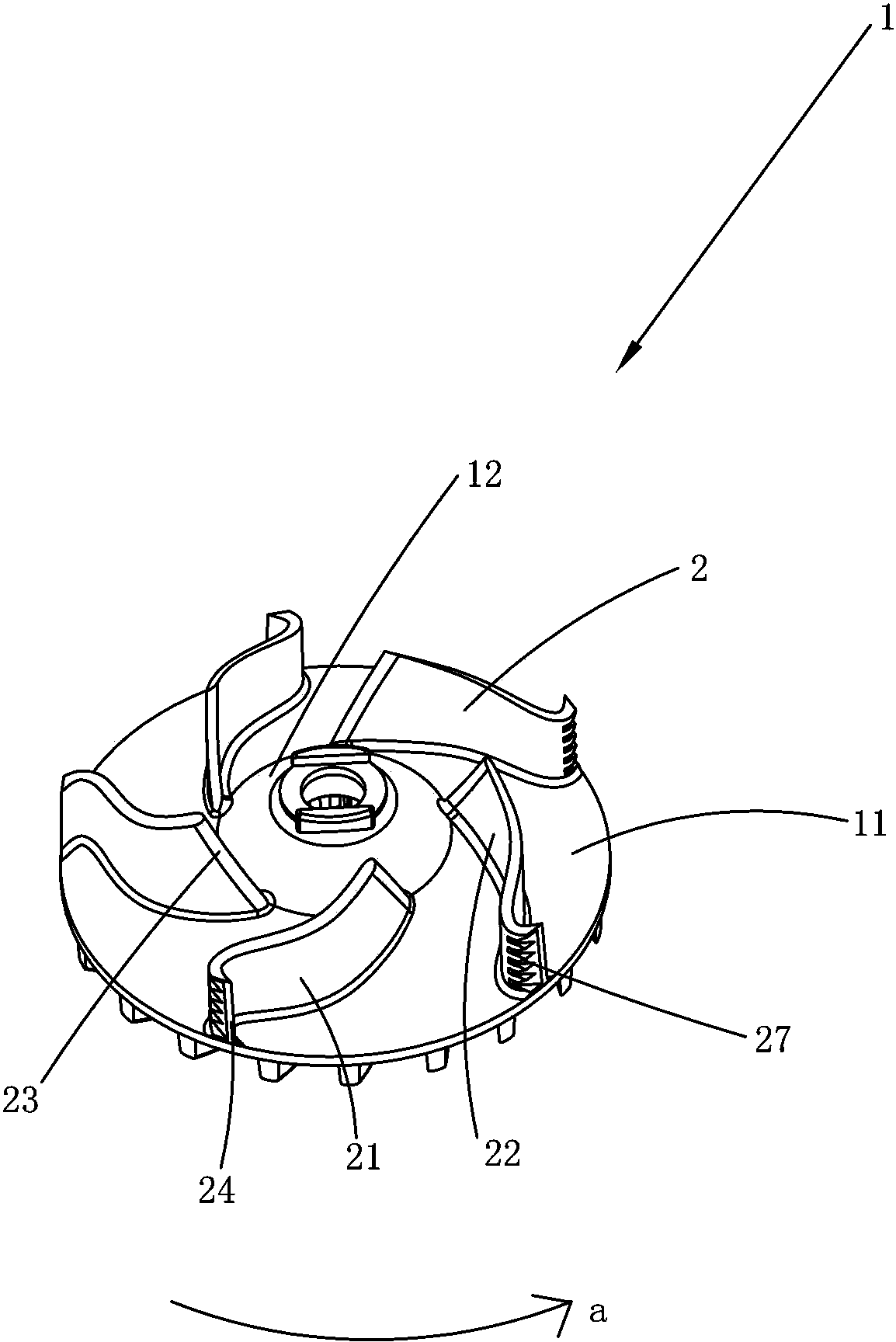

[0025] see figure 1 As shown, the air blower includes a main body housing 8 provided with an operating handle 3 . The main body housing 8 is provided with an air inlet 4 and an air outlet 5 . The main body housing 8 is provided with a motor 6 and a fan 1 . The operating handle 3 is provided with a switch 7 for controlling the opening and closing of the motor 6 . After the switch 7 is activated, the fan 1 rotates at a high speed under the drive of the motor 6 and generates negative pressure, so that the airflow enters from the air inlet 4 and flows out from the air outlet 5 rapidly. The air inlet 4 and the air outlet 5 can be connected to the corresponding blowing and absorbing parts respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com