Tunnel model test platform with complex loading-unloading work condition considered

A technology of tunnel model and test platform, which is applied in soil material testing, material inspection products, etc., can solve the problems of difficult test execution and limited loading capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

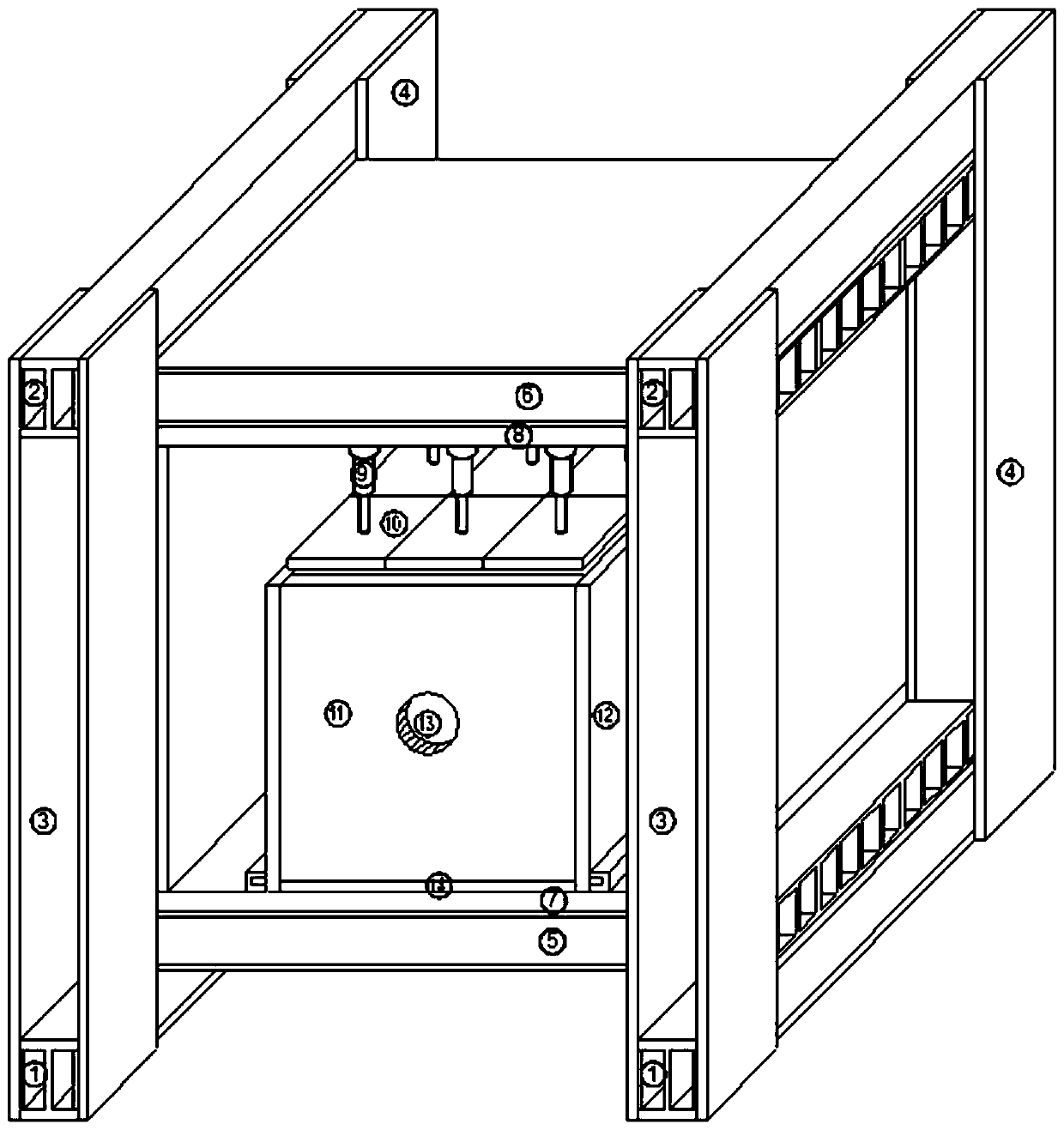

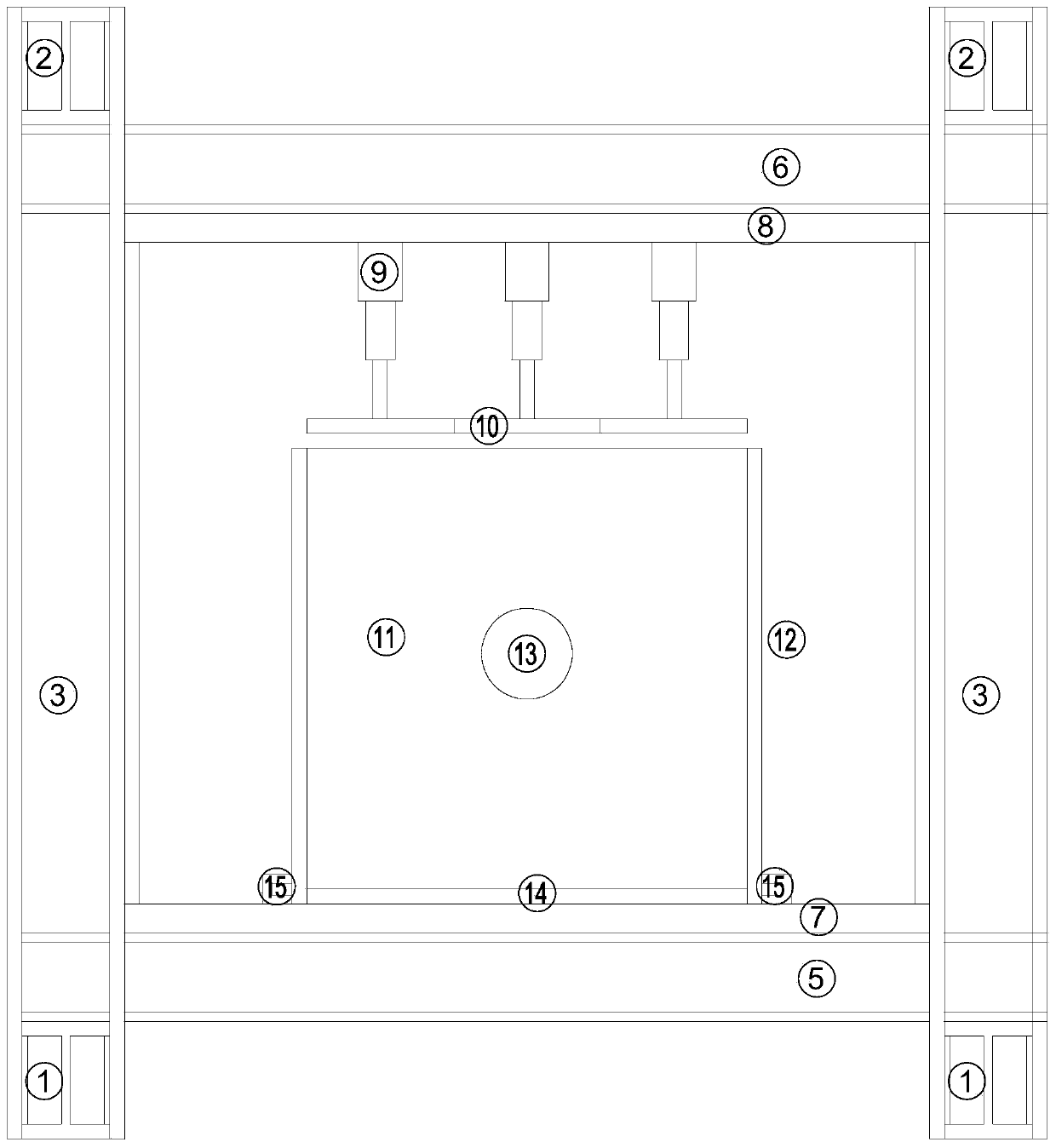

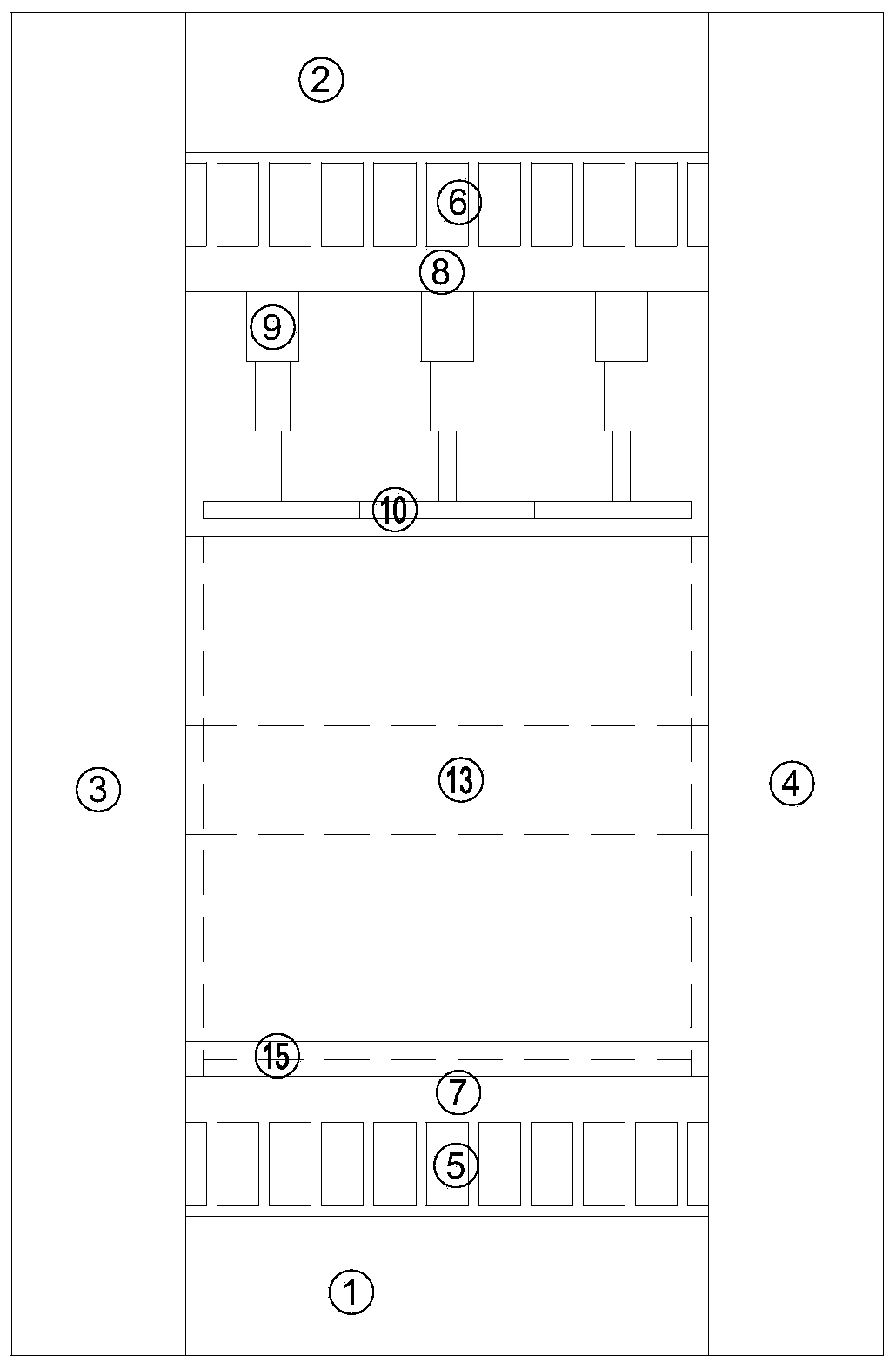

[0045] Such as Figure 1-4 As shown, the present invention proposes a tunnel model test platform that can consider complex loading and unloading conditions, and is used for the simulation of complex working conditions in close-to-operation tunnel construction. The platform includes a self-balancing frame subsystem, a model test box system, a loading control Subsystem, automatic monitoring subsystem.

[0046] The loading subsystem adopts a modular design and relies on the self-balancing frame subsystem. The loading subsystem includes nine independent loading and unloading jacks arranged in a nine-square grid on the plane. Different loading and unloading combinations can be realized through the loading plate on the top of the jack. It can complete the simulation of complex construction conditions close to the operating tunnel, including the overall (partial) excavation (loading) of the tunnel top and the overall (local) excavation (loading) of the side.

[0047] The balanced fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com