Explosion-proof device for high-voltage cable terminal

A technology of high-voltage cables and explosion-proof devices, which is applied in cable terminals, fire rescue, etc., can solve problems such as injury, fire extinguishing, and inability to suppress flames, and achieve the effects of simple and convenient operation, reduced losses, and reduced threats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

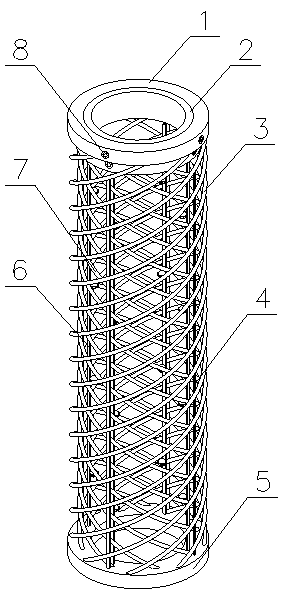

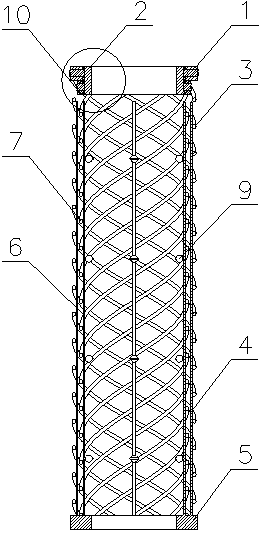

Embodiment 1

[0021] The high-voltage cable terminal explosion-proof device of the present invention is realized in this way, consisting of an outer swivel (1), an upper fixing sleeve (2), an outer protective rib (3), an outer support rod (4), a lower fixing sleeve (5), an inner support Rod (6), inner protective rib (7), top screw (8), small dry powder fire extinguishing ball (9), inner swivel ring (10), sliding slot (11) and placement sleeve (13), multiple One end of the outer strut (4) is vertically placed on the lower fixing sleeve (5), a plurality of the outer struts (4) are distributed at an equal angle, and the other end of the outer strut (4) extends vertically upwards, more The outer protective ribs (3) are spirally wound at an equal angle and placed on the outer struts (4), one end of the outer protective ribs (3) is connected to the lower fixing sleeve (5), and the multiple inner struts (6) One end is vertically placed on the lower fixing sleeve (5), and a plurality of inner strut...

Embodiment 2

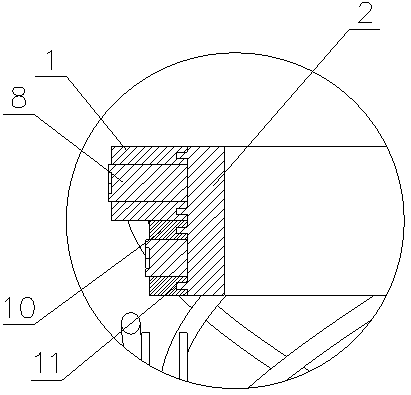

[0025] The difference between this embodiment and Embodiment 1 is: the inner strut (6) is equipped with a telescopic inner telescopic rod (12), and the outer strut (4) is equipped with a telescopic outer telescopic rod ( 14); when in use, it can be stretched and adapted according to the distance between the upper fixing sleeve (2) and the lower fixing sleeve (5), so as to facilitate the support of the outer protective rib (3) and the inner protective rib (7);

[0026] The design of the sliding insert block and the sliding slot (11) limits the outer swivel (1) and the inner swivel (10);

[0027] The outer diameter of the upper fixing sleeve (2) is designed to be smaller than the outer diameter of the lower fixing sleeve (5), which is convenient for placing the outer swivel (1) and inner swivel (10) on the upper fixing sleeve (2);

[0028] The inner diameter of the upper fixing sleeve (2) is designed to be equal to the inner diameter of the lower fixing sleeve (5), which is adapte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com