Automatic timed irrigation device for agricultural production

An automatic irrigation and agricultural technology, which is applied in drinking water devices, agriculture, water supply devices, etc., can solve problems such as the inability to use rainwater reasonably and effectively, the death of crops due to drought, and the inability to irrigate agricultural products, so as to meet irrigation needs, make full and reasonable use, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

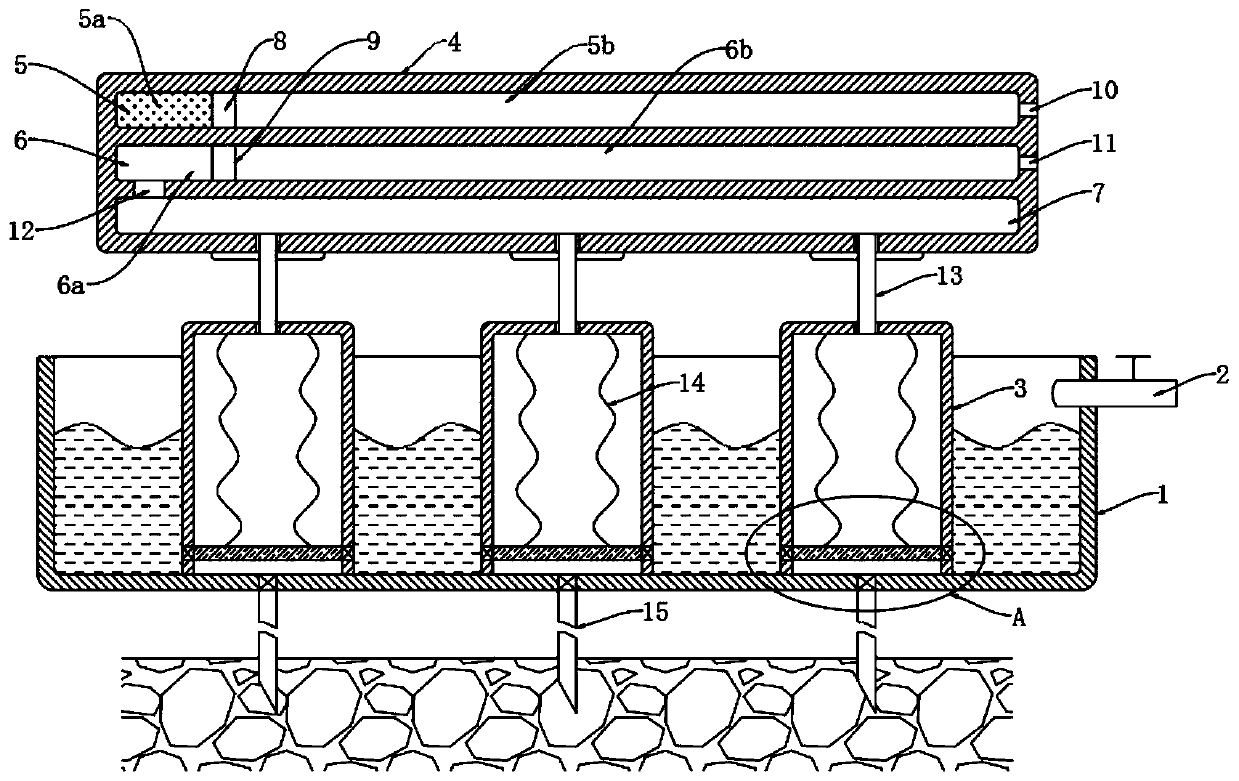

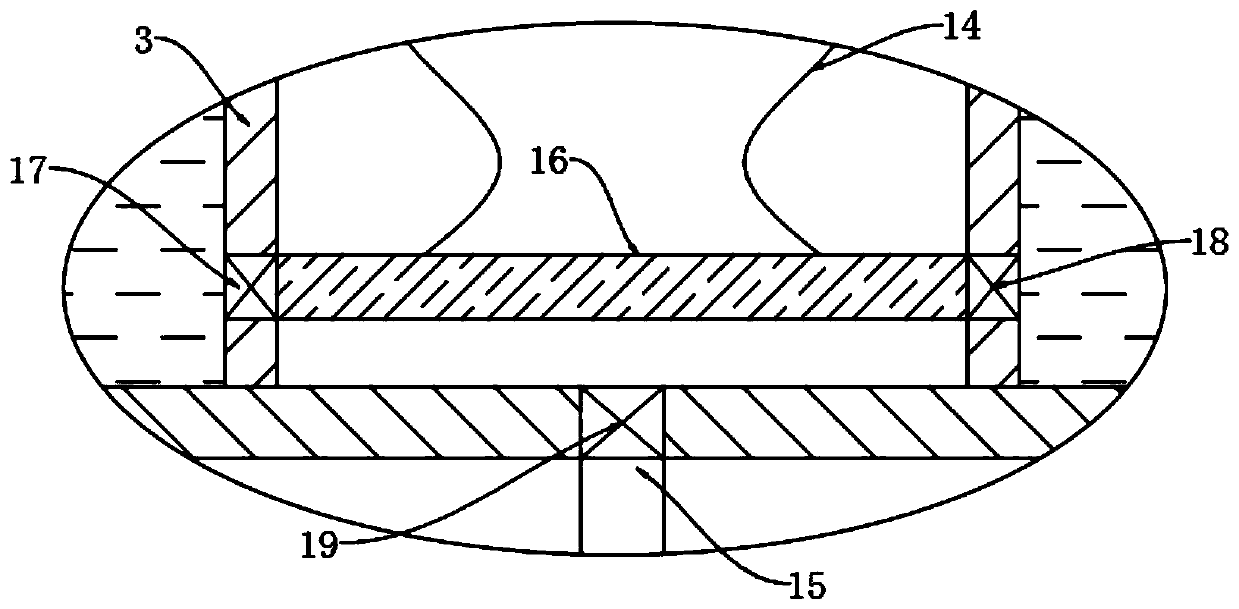

[0019] refer to Figure 1-2 , a timing automatic irrigation device for agricultural production, comprising a water storage tank 1 and a sun visor 4, the upper end of the side wall of the water storage tank 1 is connected with a water inlet pipe 2, and the inner bottom of the water storage tank 1 is uniformly equipped with a water collection cover 3 with an inverted buckle. The first slide chamber 5, the second slide chamber 6 and the third slide chamber 7 are opened in the sun visor 4 from top to bottom in sequence, and the ends of the sun visor 4 are provided with air ducts 13 communicating with the upper end of the water collecting cover 3 , the upper end of the air duct 13 communicates with the third sliding cavity 7, the first sliding cavity 5 and the second sliding cavity 6 are respectively sealed and slidably connected with a first magnetic block 8 and a second magnetic block 9, and the first magnetic block 8 connects the first magnetic block to the second sliding cavity....

Embodiment 2

[0028] The difference from Embodiment 1 is that the shape of the sun visor 4 is a roof shape with a high middle and low sides, and the length of the water storage tank 1 is greater than that of the sun visor 4 .

[0029] In this embodiment, it is ensured that in rainy weather, the rainwater falling on the upper end of the sun visor 4 can flow into the water storage tank 1 along the sun visor 4 for storage, so that the rainwater can be used reasonably and effectively, which can not only avoid the loss of agricultural products during the rainy season. The phenomenon of waterlogging caused by too much water can make full use of rainwater, irrigate agricultural products when needed, and save water resources.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com