Unexpected slide preventing type double-layer raft frame

An accident-preventing, double-layer technology, applied to devices for throwing or releasing ships, and ship fixing/storage, etc., can solve problems such as wire rope corrosion and aging, safety hazards, and ship economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Further description will be given below in conjunction with the accompanying drawings and embodiments.

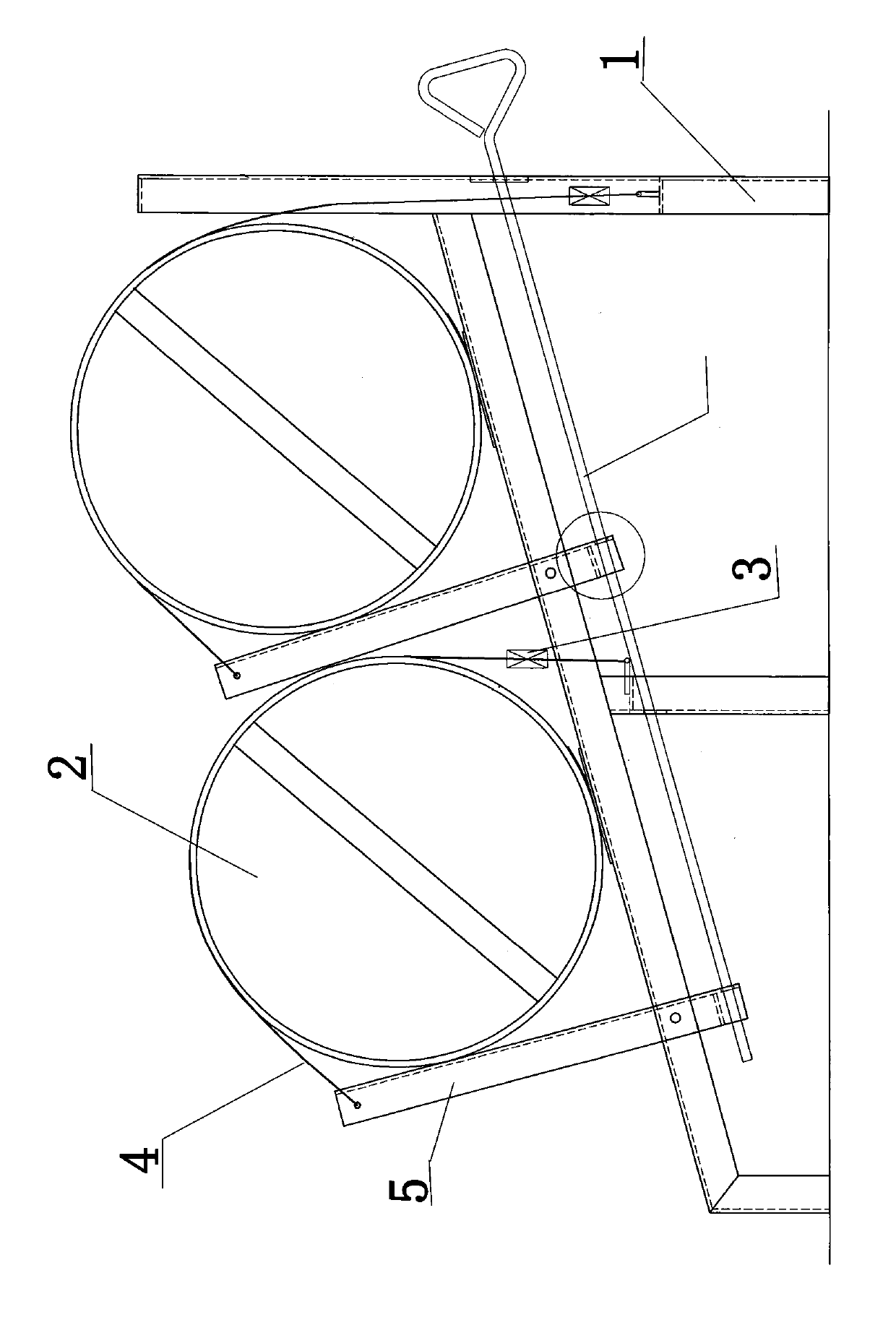

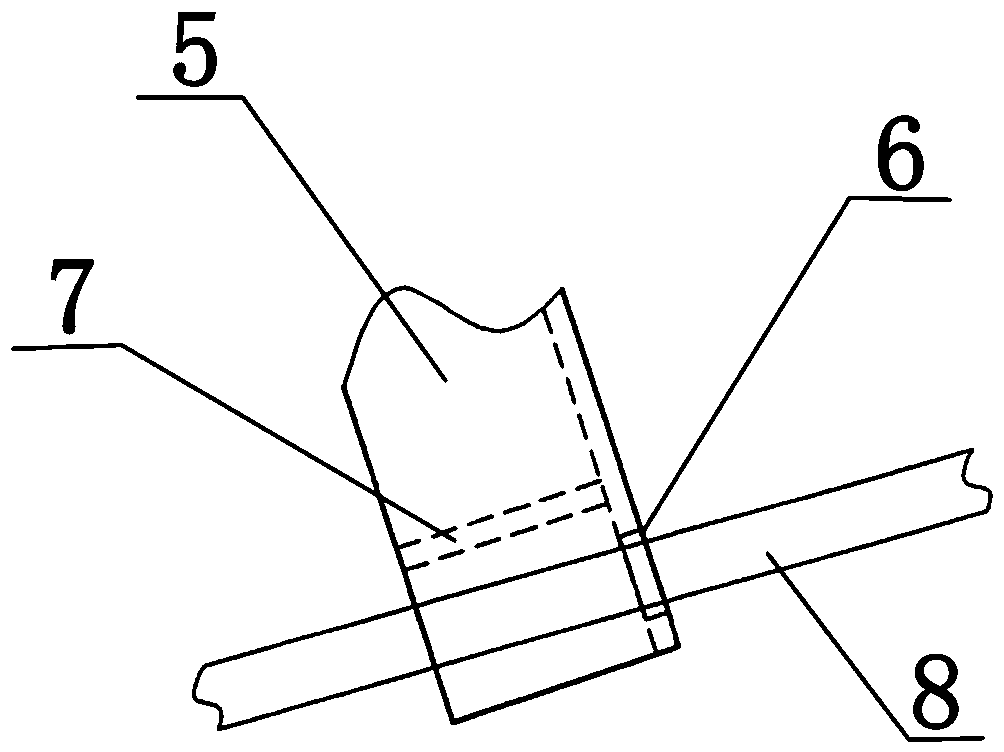

[0011] figure 1 , 2 Shown: a double-layer raft frame for preventing accidental slipping includes an inclined base 1 , a hydrostatic pressure release device 3 , a fastening cable 4 , a gear rod 5 , a baffle plate 7 , and a limit rod 8 . The middle and lower parts of more than one gear bar 5 are hinged on the inclined base 1 and are evenly distributed along the inclination direction of the inclined base. On the inclined base 1, the limit rod 8 is parallel to the inclined direction of the inclined base 1 and connected to the lower part of the inclined base to be in a state of being able to move and pull along the inclined direction of the inclined base. 6, a baffle plate 7 is provided on the gear lever at the position above the limit hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com