A kind of paraffin wax cleaning operation pipeline robot

A pipeline robot, paraffin technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of short wax cleaning cycle, reduce flow area, and high operating cost in pipelines, and improve easy blocking. problems, improve the effect of storing electrical energy and prolong the wax cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

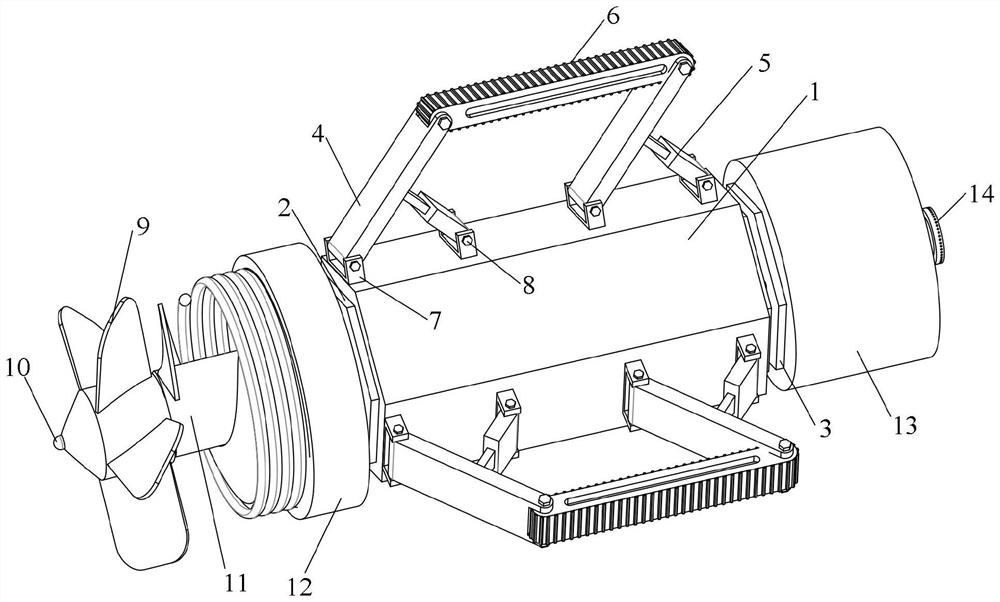

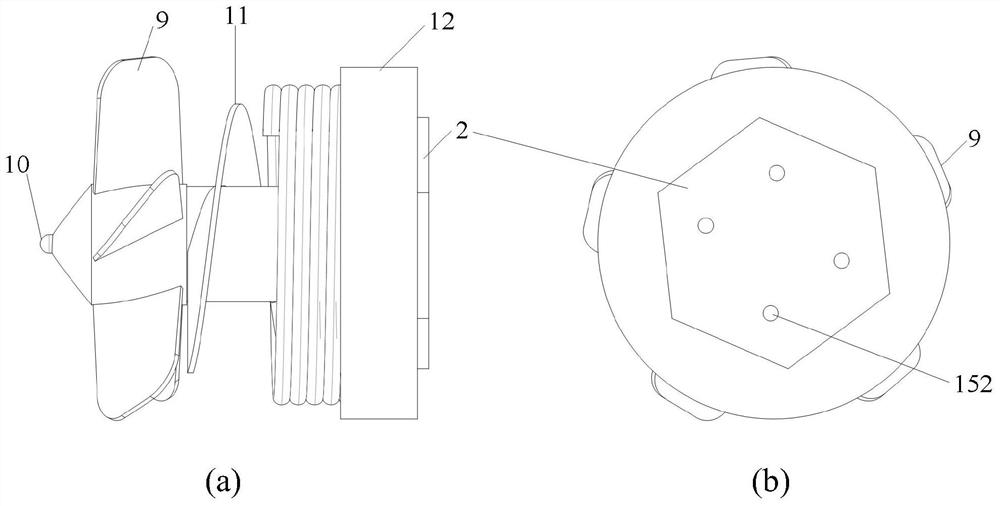

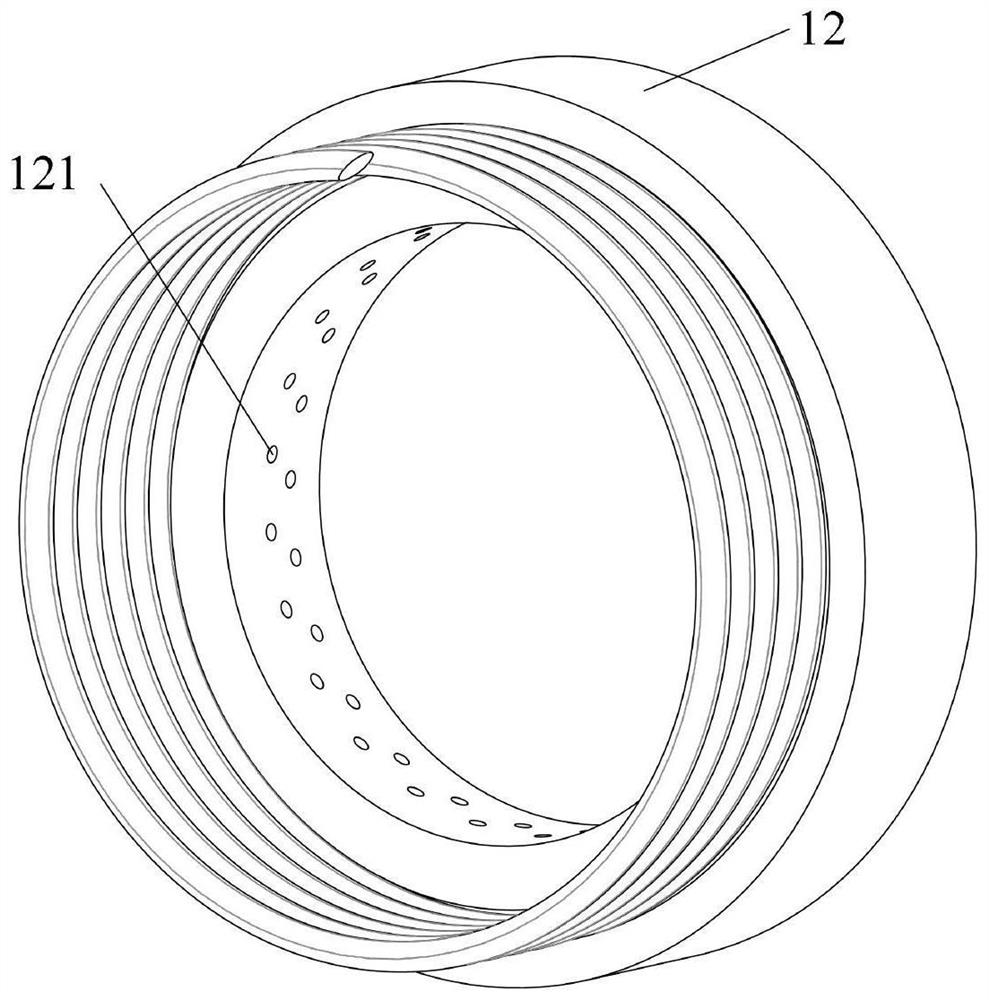

[0033] Such as Figure 1 to Figure 6 As shown, a paraffin wax cleaning operation pipeline robot is composed of an energy supply device, a walking device, a cleaning device, a paraffin collecting device, a wax preventing device, and a connecting device. The connecting device is connected with the paraffin cleaning device, and the collecting device is connected with the wax preventing device.

[0034] Such as Figure 4 As shown, the self-adaptive walking device includes three sets of chute-type support legs 4 uniformly distributed along the circumferential direction, hydraulic support rods 5 and rubber crawlers 6, and all the devices are fixed on the On the shell 1 of the energy supply device, by adjusting the angle between the chute-type support leg 4 and the hydraulic sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com