An oil field downhole wax prevention tool

A technology for oil field wells and tools, which is applied in the direction of cleaning equipment, wellbore/well parts, earthwork drilling and production, etc., which can solve the problems of chemical substance discharge, environmental pollution, and reduction of crude oil production efficiency, so as to prolong the cleaning cycle and eliminate the need for The effect of maintenance, high-efficiency wax-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

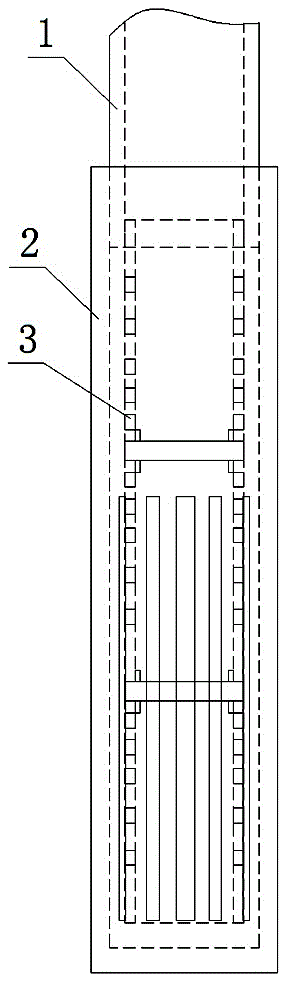

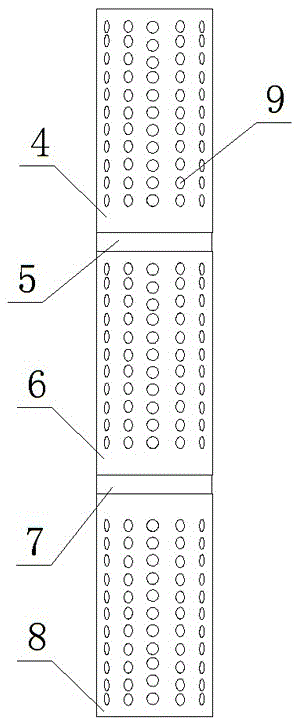

[0015] Such as figure 1 An oilfield downhole wax prevention tool is shown, the wax prevention tool is composed of an outer casing 2 and an internal active body 3, the outer casing diameter is about 60mm, the length is 600mm, the lower end is closed, and the upper end opening is threaded for connecting with the pipe joint 1 connection, there are transparent grooves with a length of 300mm and a width of 5mm on the wall of the outer casing from the lower end surface, which are evenly distributed in the radial direction, and are the channels for crude oil to enter the tool. The internal active body is a three-section cylindrical active body with a length of 190mm. They are respectively the first cylindrical active body 4, the second cylindrical active body 6, and the third cylindrical active body 8. There are hollow grooves 9 evenly distributed radially around them, which are channels for crude oil to flow upward after entering the outer casing. The total cross-sectional area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com