Jet propulsion pipeline dirt remover

A technology of jet type and decontamination machine, which is applied in the field of jet propulsion pipeline decontamination machine, can solve the problems of low cleaning efficiency, danger, affecting the sewage discharge capacity of urban pipelines, etc., and achieves the effect of thorough scraping and large scraping force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

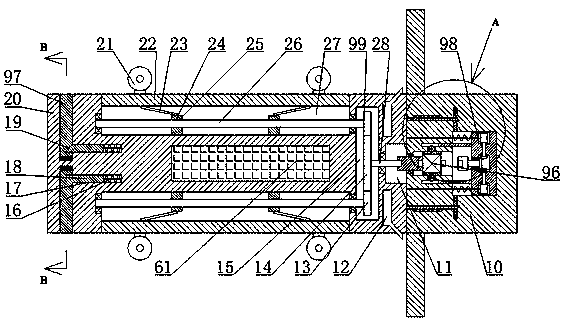

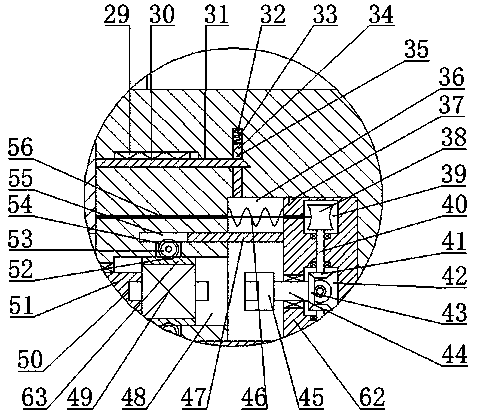

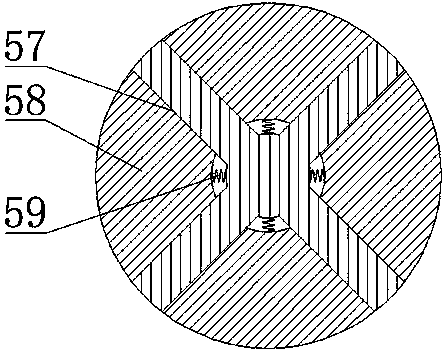

[0016] Combine below Figure 1-4 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0017] A jet propulsion pipeline decontamination machine described in conjunction with accompanying drawings 1-4 includes a fuselage 10 and a fixing frame 20 arranged on the left side of the fuselage 10, and the center of the end wall of the fuselage 10 is symmetrically distributed with The gear rod 60 fixedly connected with the fuselage 10, the center of the end wall of the fixed frame 20 is symmetrically distributed with four guide chute 27 opening outward, and the left and right symmetrical Moving block 24, the two left and right moving blocks 24 are provided with left and right threaded holes 25 with reverse threads, the threaded holes 25 are internally threaded with threaded rods...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com