Suction hood interlocking time delay switch mechanism and wood planing machine using same

A technology of time-delay switch and dust hood, which is applied in wood processing appliances, manufacturing tools, and processing machines for manufacturing flat surfaces, etc., can solve the problems of unprotected tool shafts and hidden dangers of operator safety, and achieves the elimination of hidden dangers and safety. high coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

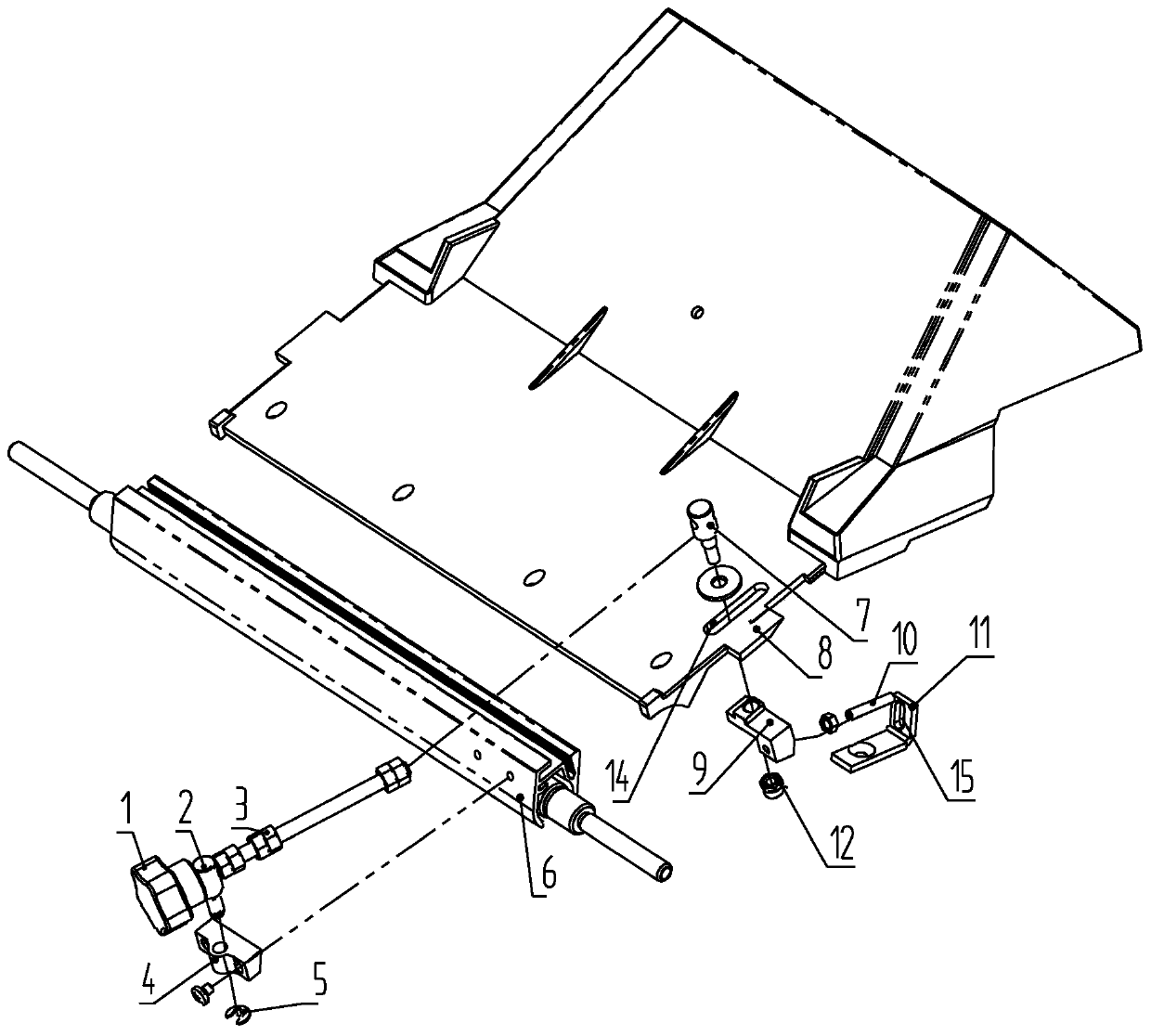

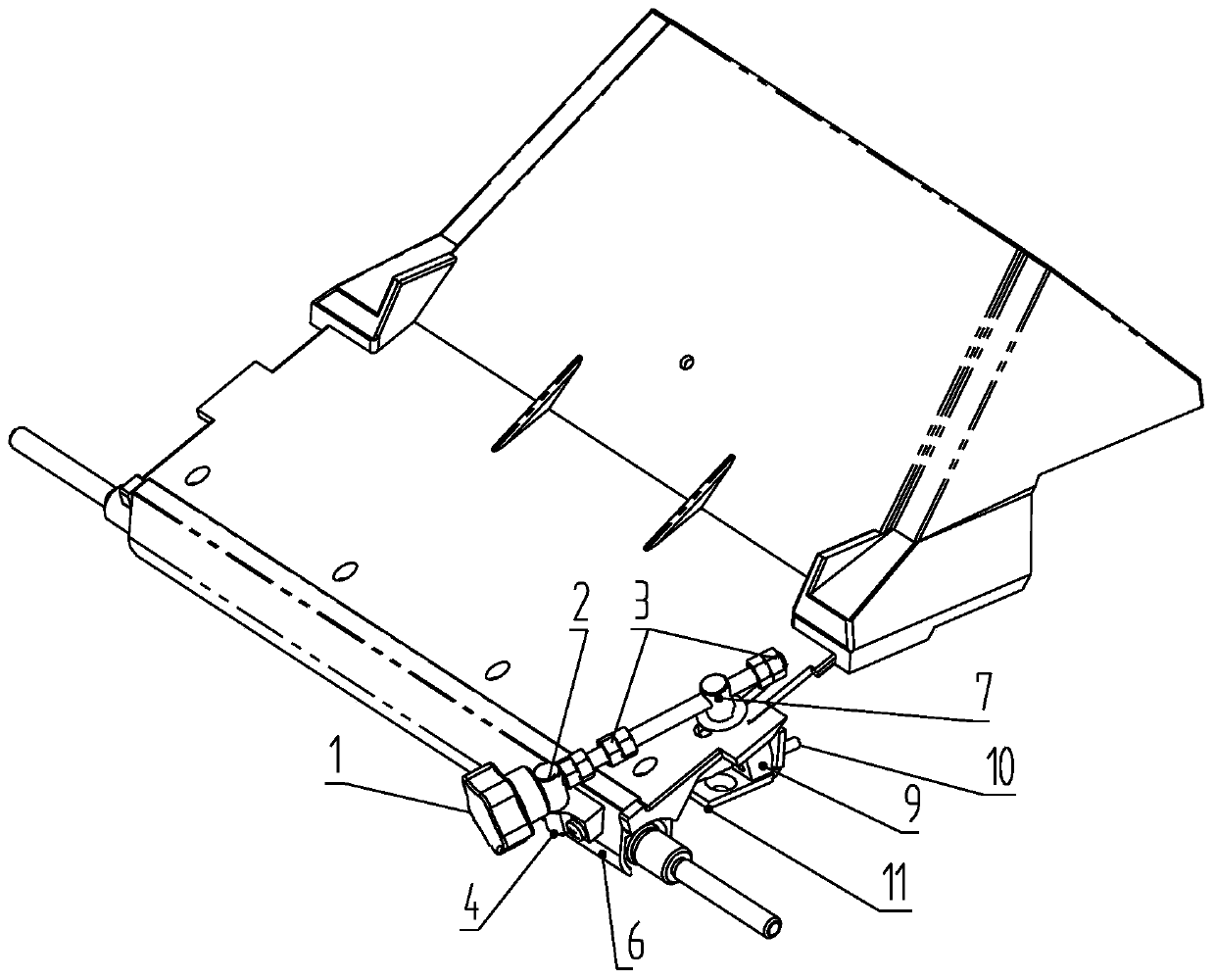

[0026] Example 1, such as figure 1 and figure 2 As shown, a vacuum hood interlock delay switch mechanism applicable to woodworking planers includes a silk shaft 1 , a fixed support shaft 2 , a sliding shaft 7 and a sliding seat 9 connected in sequence.

[0027] Wherein, a horizontal long slot hole 14 is arranged on the dust collection cover 8; along the vertical direction of the dust collection cover 8, the sliding shaft 7 passes through the horizontal long slot hole 14 and is connected with the sliding seat 9 at the bottom of the dust collection cover 8, and the sliding shaft 7 After passing through the sliding seat 9, it is locked and fixed by the self-locking nut 12;

[0028] A limiting plate 11 is installed on the frame 16 of the woodworking planer, and the limiting plate 11 is provided with a vertical slotted hole 15;

[0029] Install the stop screw 10 that is tightened by the nut on the sliding seat 9, before the dust collection cover is opened, the stop screw 10 pass...

Embodiment 2

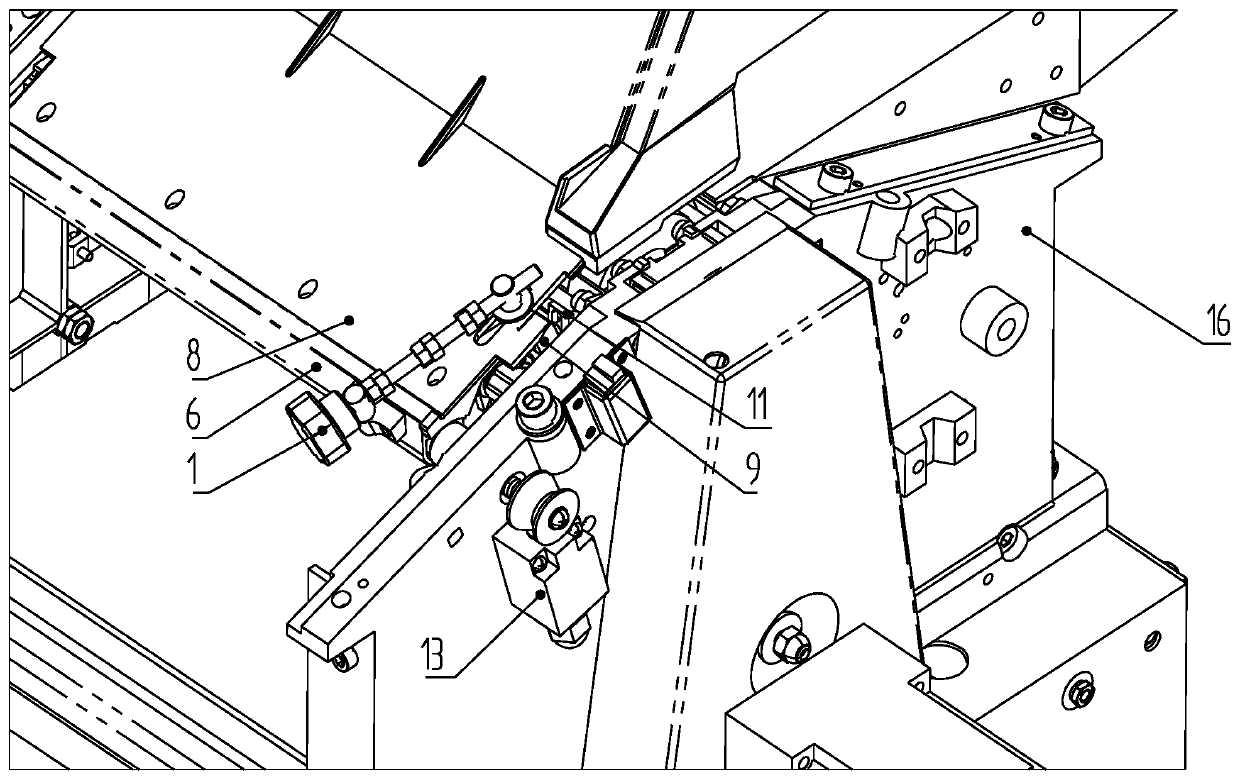

[0033] Example 2, such as image 3 As shown, a new type of woodworking planer is realized by applying the design of the above-mentioned interlocking delay switch mechanism of the dust collection hood.

[0034] The dust collection hood 8 is installed and connected with the shield rotation shaft 6 , and then the dust collection hood 8 is integrally installed on the frame 16 through the shield rotation shaft 6 . Under the situation of normal work, the effect that dust suction cover 8 is covered above the cutter shaft to play safety protection.

[0035] For eliminating potential safety hazards, when the operator opens the initial moment of the dust collection cover 8, the cutter shaft should stop completely.

[0036] In this regard, the application proposes the design of the above-mentioned interlocking delay switch mechanism. A sliding shaft 7 that can move forward and backward is provided on the dust collection cover 8. A sliding seat 9 with a wedge-shaped structure is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com