Automatic grooving machine for house decoration customized furniture mounting

A slotting machine and furniture technology, applied in the direction of manufacturing tools, stone processing tools, work accessories, etc., can solve problems such as impact, operator safety hazards, laborious slotting operations, etc., to improve integrity, improve work efficiency, improve The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

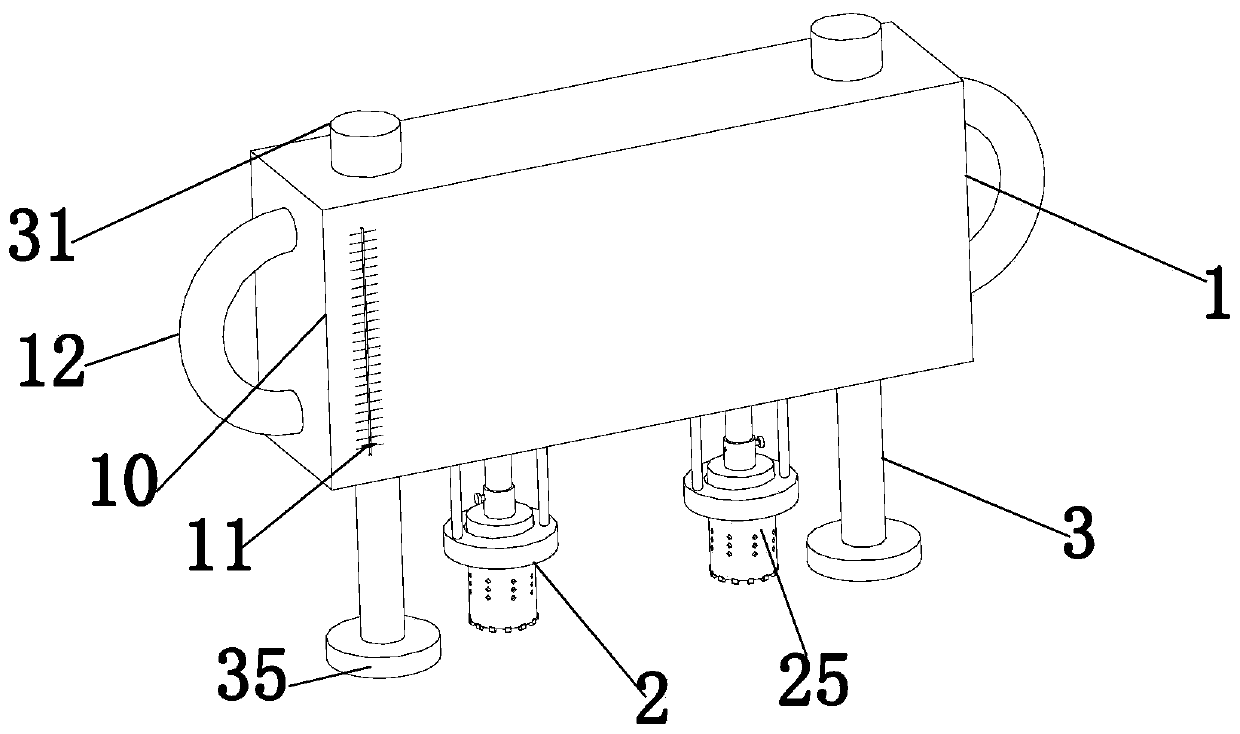

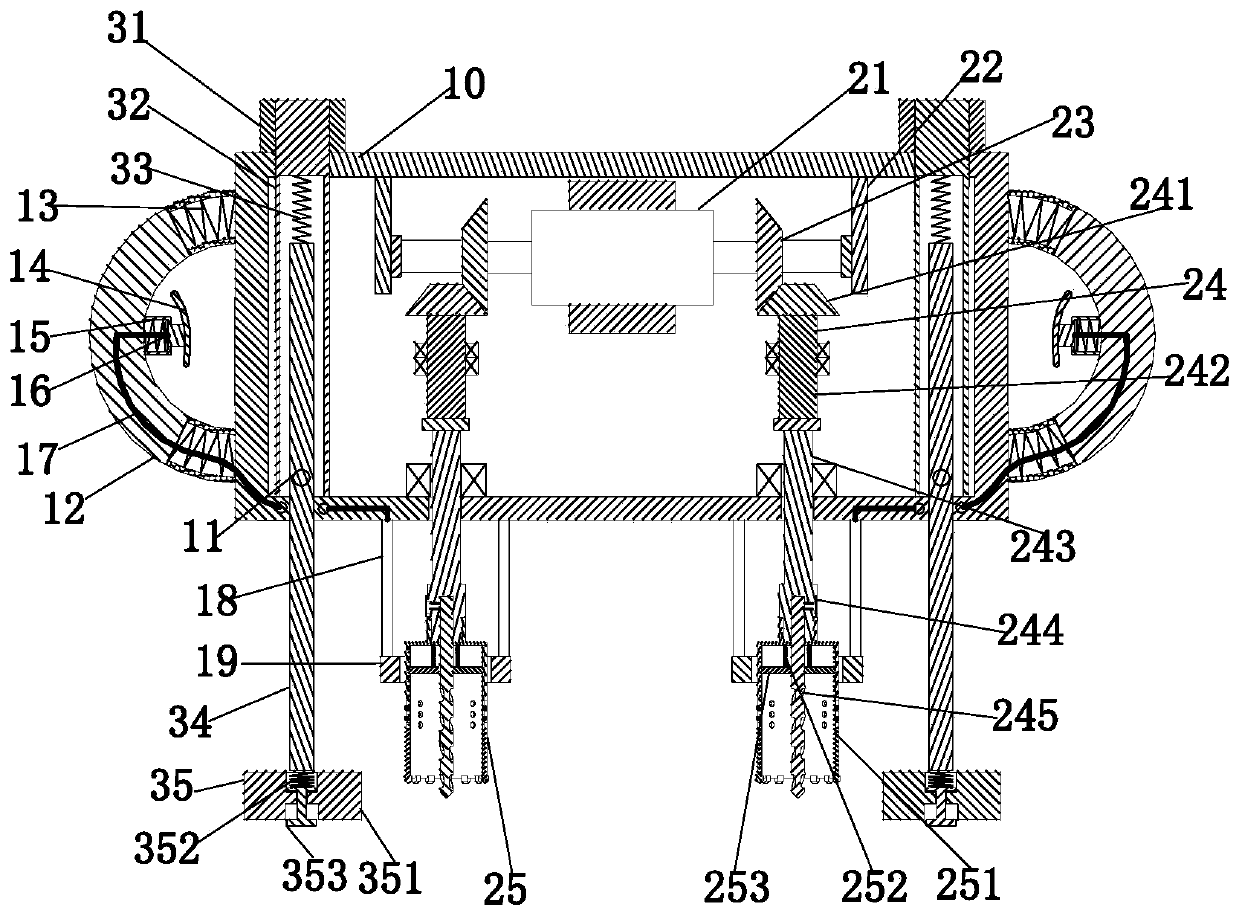

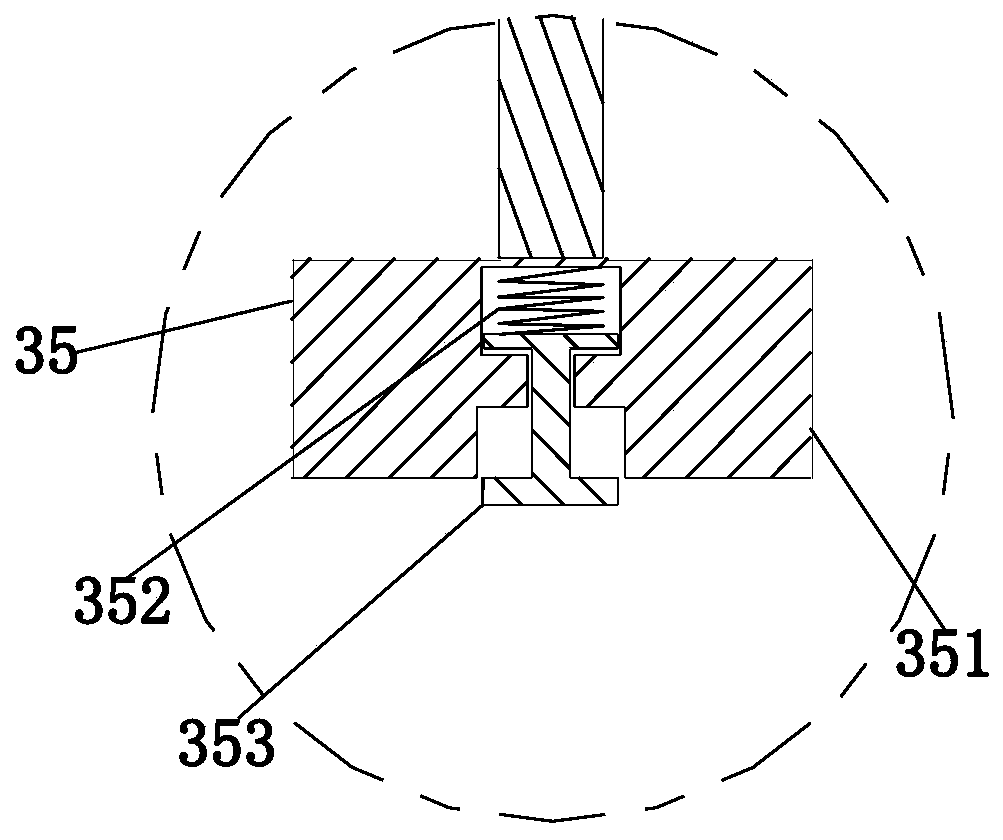

[0026] Such as Figure 1 to Figure 4 As shown, an automatic slotting machine for custom-made furniture installation for house decoration, including a box body 1, an actuator 2 and a support and cushioning mechanism 3, the inside of the box body 1 is a cavity structure, which is located inside the box body 1 There is an actuator 2, and a support and cushioning mechanism 3 is arranged symmetrically inside the box body 1, and the support and cushioning mechanism 3 is distributed on both sides of the actuator 2; wherein:

[0027] The box 1 includes a casing 10, a pointer 11, an arc handle 12, a shock absorbing spring 13, a material return switch 14, a collar 15, an auxiliary spring 16, an electromagnetic control line 17, a boom 18 and a magnetic control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com