A device for preventing glue overflow in laminated glass processing

A technology of laminating glass and overflowing glue, applied in the directions of lamination devices, lamination auxiliary operations, chemical instruments and methods, etc., can solve the problems of inconvenient use of sealing tape, insufficient air tightness, environmental pollution, etc. Roll, easy wrapping, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

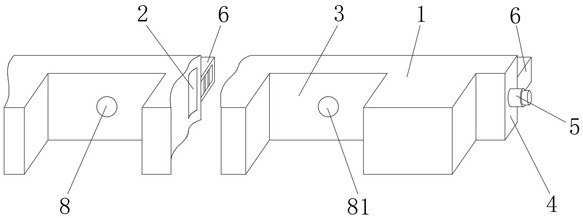

[0028] see Figure 1-4 , this embodiment provides a laminated glass processing anti-glue device, including a sealing strip 1, the interior of the sealing strip 1 is provided with a chamber 2, one side of the sealing strip 1 is provided with a plurality of gaps 3, a plurality of gaps 3 Equidistantly arranged along the sealing strip 1 , sealing plates 4 are integrally provided at both ends of the chamber 2 , and an airtight plug 5 is provided at the center of one of the sealing plates 4 .

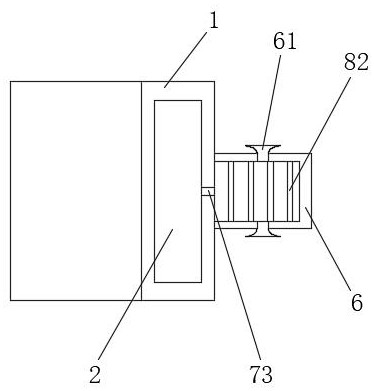

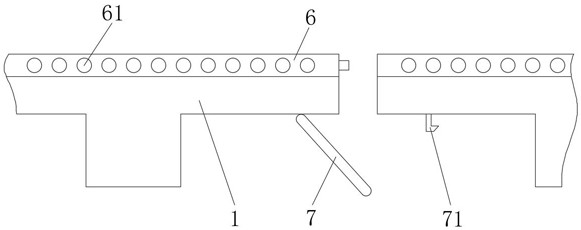

[0029] The side of the sealing strip 1 away from the notch 3 is integrally provided with a load-bearing strip 6, and the symmetrical axis between the load-bearing strip 6 and the sealing strip 1 along the horizontal direction coincides. The front section of the load-bearing strip 6 is U-shaped, and the top of the load-bearing strip 6 A plurality of suction cups 61 are integrally provided on the side and the bottom side, and the bottom ends of the suction cups 61 are connected with the inside ...

Embodiment 2

[0041] see Figure 1-4 , the inner wall of the load-bearing bar 6 is integrally provided with a plurality of load-bearing bars 82 along the vertical direction, and the plurality of load-bearing bars 82 are arranged in a matrix inside the load-bearing bar 6, and the load-bearing bar 6 can be squeezed when the load-bearing bar 6 is pressed. , will not produce deformation, and can ensure that the airtightness between the glasses will not be damaged. The sealing sleeve 52 is sleeved on the end of the ventilation rod 51 provided with the through hole 53, and the ventilation rod 51 can be connected to the outside through the sealing sleeve 52. However, the effect of sealing the interior of the ventilation rod 51 improves the airtightness of the chamber 2 .

[0042] One side of the sealing strip 1 is provided with a plurality of gaps 3, and the plurality of gaps 3 are equidistantly arranged along the sealing strip 1, and the sealing strip 1 can be folded through the gaps 3, which not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com