Automatic product grabbing device

A technology for grabbing devices and products, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of high labor intensity, low production efficiency, and affecting the working level of automated production lines, so as to stabilize product quality, improve production efficiency, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

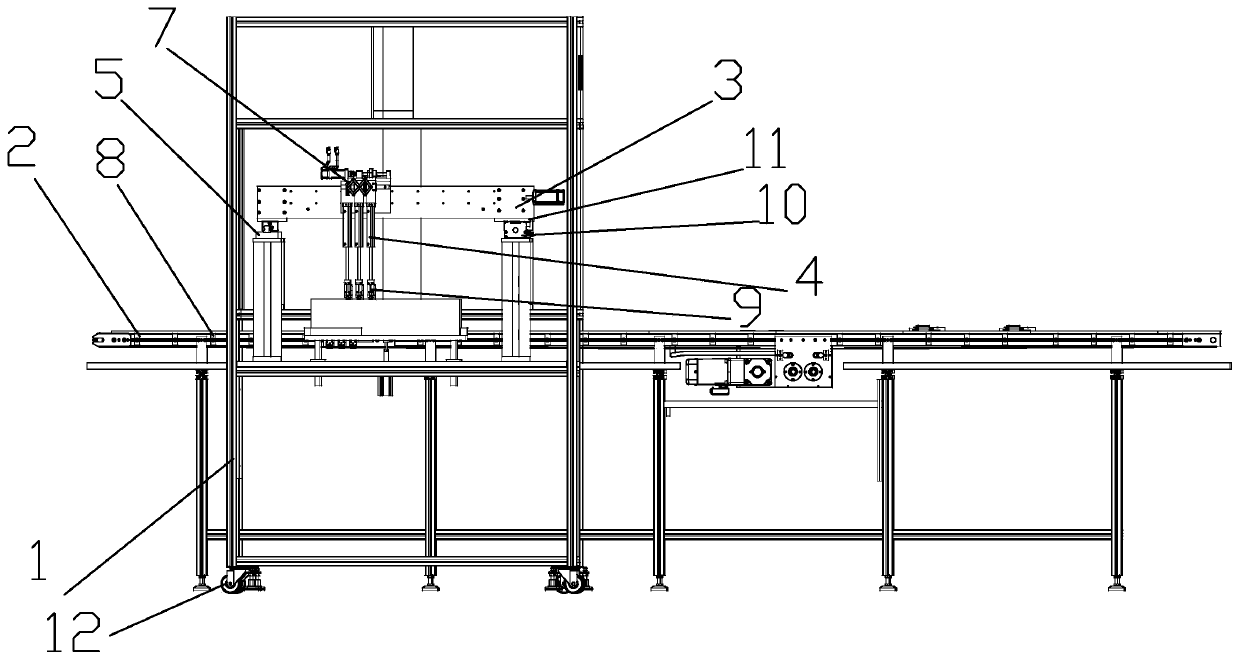

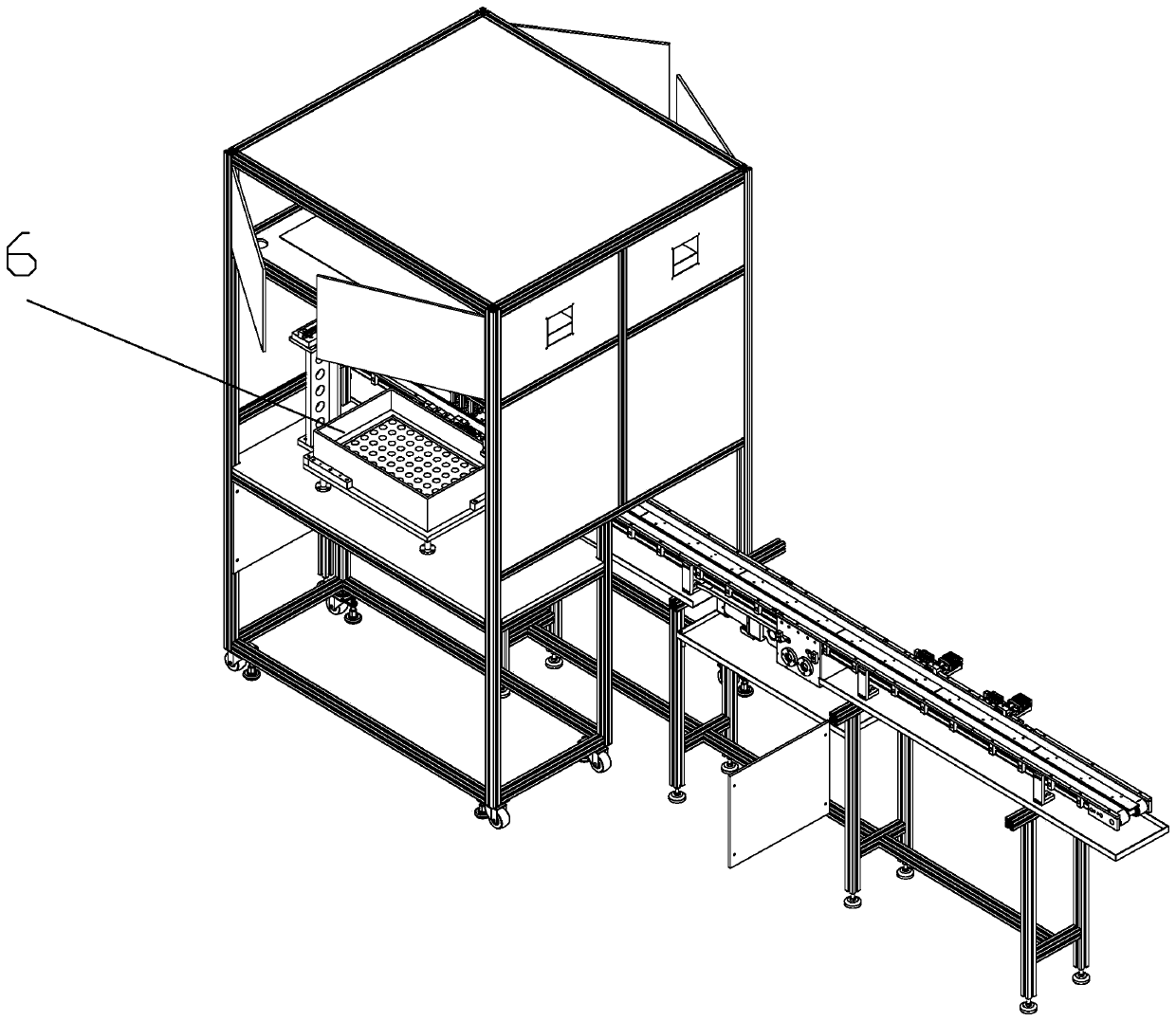

[0020] see Figure 1-2 , the embodiment of the present invention includes:

[0021] An automatic product grabbing device, comprising: a first rail 2, a second rail 3 arranged on a support 1, a plurality of hand gripping structures 4 moving vertically, a transport mechanism 5, and a PLC, and the PLC is respectively connected to The first track, the second track, a plurality of hand grasping structures moving in the vertical direction, and the delivery mechanism are electrically connected, and the PLC sends out a cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com