A kind of polyimide fiber and preparation method thereof

A technology of polyimide fiber and polyamic acid fiber, applied in the fiber field, can solve the problems of poor processing repeatability, large specific surface area of nanoparticles, and poor heat aging resistance of organic small molecules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

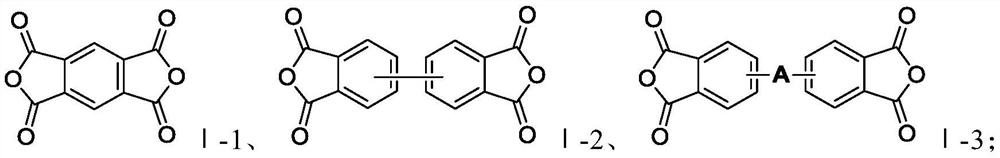

[0054] The invention provides a kind of preparation method of polyimide fiber, comprises the following steps:

[0055] a) Aromatic dianhydride monomers and diamine monomers are polymerized in a solvent to obtain polyamic acid spinning stock solution;

[0056] b) spinning the polyamic acid spinning stock solution to obtain polyamic acid fibers;

[0057] c) performing imidization treatment on the polyamic acid fibers to obtain polyimide fibers;

[0058] The diamine monomer comprises monomer A and monomer B;

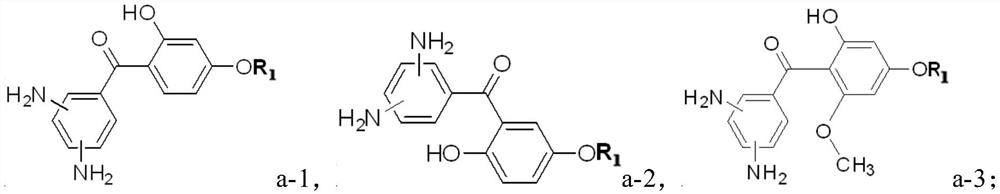

[0059] The monomer A is selected from one or more of the structures shown in formula a-1 to formula a-3:

[0060]

[0061] Among them, R 1 selected from: alkyl, substituted or unsubstituted phenyl;

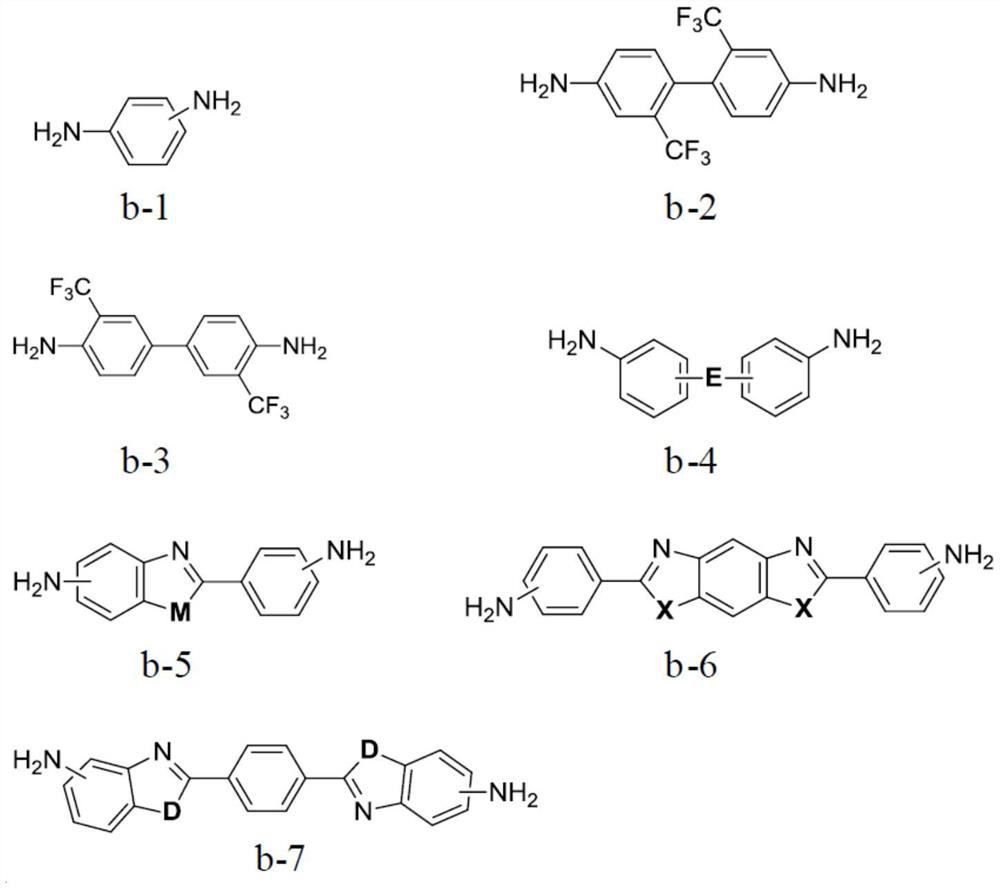

[0062] The monomer B is selected from one or more of the structures shown in formula b-1 to formula b-7:

[0063]

[0064] in,

[0065] M is selected from -O-, -S-, or -NH-;

[0066] X is selected from -O-, -S-, or -NH-;

[0067] D is selected from -O-, -S-, or -NH-...

preparation example 1

[0217] Raw material preparation example 1 Monomer A-(3,5-diaminophenyl)(2-hydroxy-4-hexyloxyphenyl)methanone

[0218] (1) 37.24 grams (0.30 moles) of 3-methoxyphenol, 54.47 grams (0.33 moles) of n-hexane bromide, 49.76 grams (0.36 moles) of potassium carbonate, 2.49 grams (0.015 moles) of potassium iodide and 275 grams of acetonitrile were added successively into the reaction bottle, and then heated the reaction system to 80 ° C for 6 hours. After being cooled to room temperature, it was added to 1500 milliliters of water, the product was extracted with dichloromethane, dried over anhydrous magnesium sulfate, the solvent was concentrated, and 53.74 grams of the representative compound 1-hexyloxy-3-methoxyl group of the structure shown in formula (II) was obtained through purification. The refined product of phenylbenzene, the yield is 86.0%.

[0219] 1 H NMR (400MHz, DMSO) δ = 7.152 (t, J = 8.0Hz, 1H), 6.445-6.510 (m, 3H), 3.920 (t, J = 6.4Hz, 2H), 3.718 (s, 3H), 1.735 -1.6...

preparation example 2

[0226] Raw material preparation example 2 Monomer A-(3,5-diaminophenyl)(2-hydroxy-4-(4-fluorophenoxy)phenyl)methanone

[0227] (1) 62.07 grams (0.50 moles) of 3-methoxyphenol, 78.75 grams (0.45 moles) of p-bromofluorobenzene, 4.76 grams (0.025 moles) of cuprous iodide, 82.93 grams (0.60 moles) of potassium carbonate and 420 grams N,N-dimethylformamide was sequentially added into the reaction flask, and the reaction system was heated to 150° C. for 8 hours under the protection of nitrogen. After being cooled to room temperature, it was added to 2500 milliliters of water, the product was extracted with dichloromethane, washed with dilute hydrochloric acid, dried over anhydrous magnesium sulfate, the solvent was concentrated, and 77.58 grams of the representative compound 1-(4-fluoro The refined product of phenoxy)-3-methoxybenzene, the yield is 79.0%.

[0228] 1 H NMR (400MHz, DMSO) δ=7.295–7.175(m,3H),7.105–7.025(m,2H),6.703(dd,J=8.4Hz,2.2Hz,1H),6.557(t,J=2.2Hz , 1H), 6.504 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com