Cabin door structure of front overhead door of passenger car

A cabin door and passenger car technology, which is applied to the front flap door structure field of passenger cars, can solve the problems of low degree of automation and labor, and achieve the effect of convenient closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

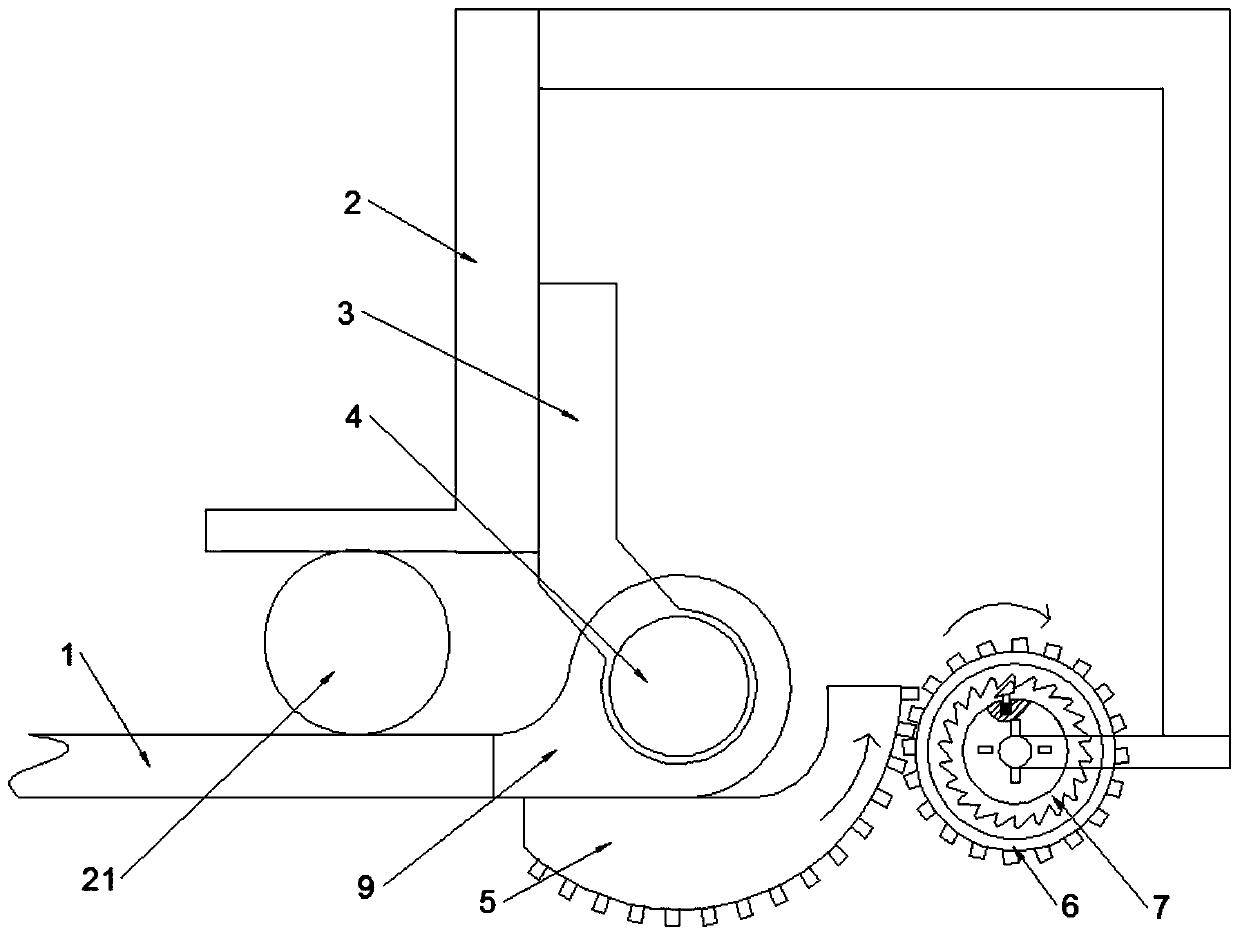

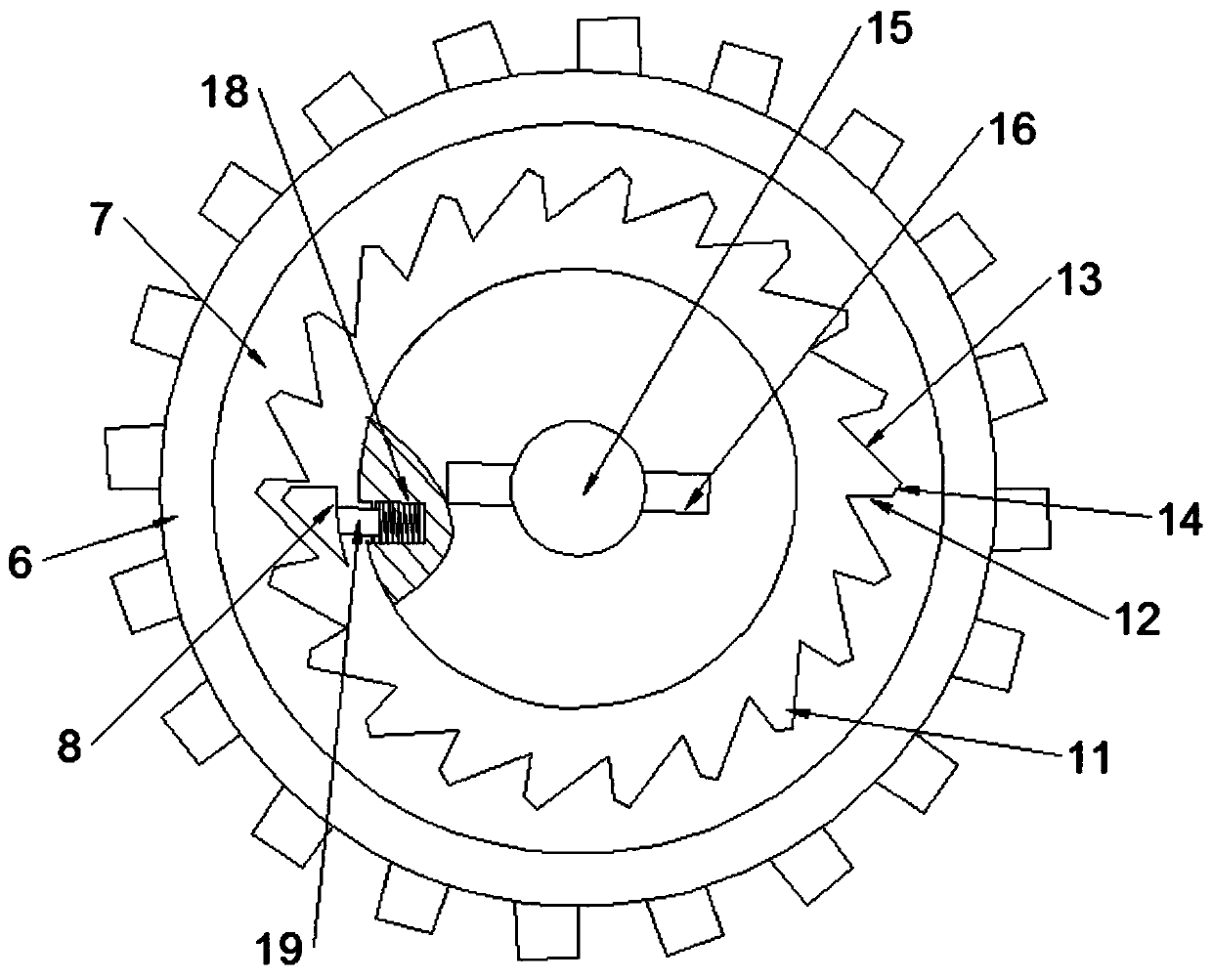

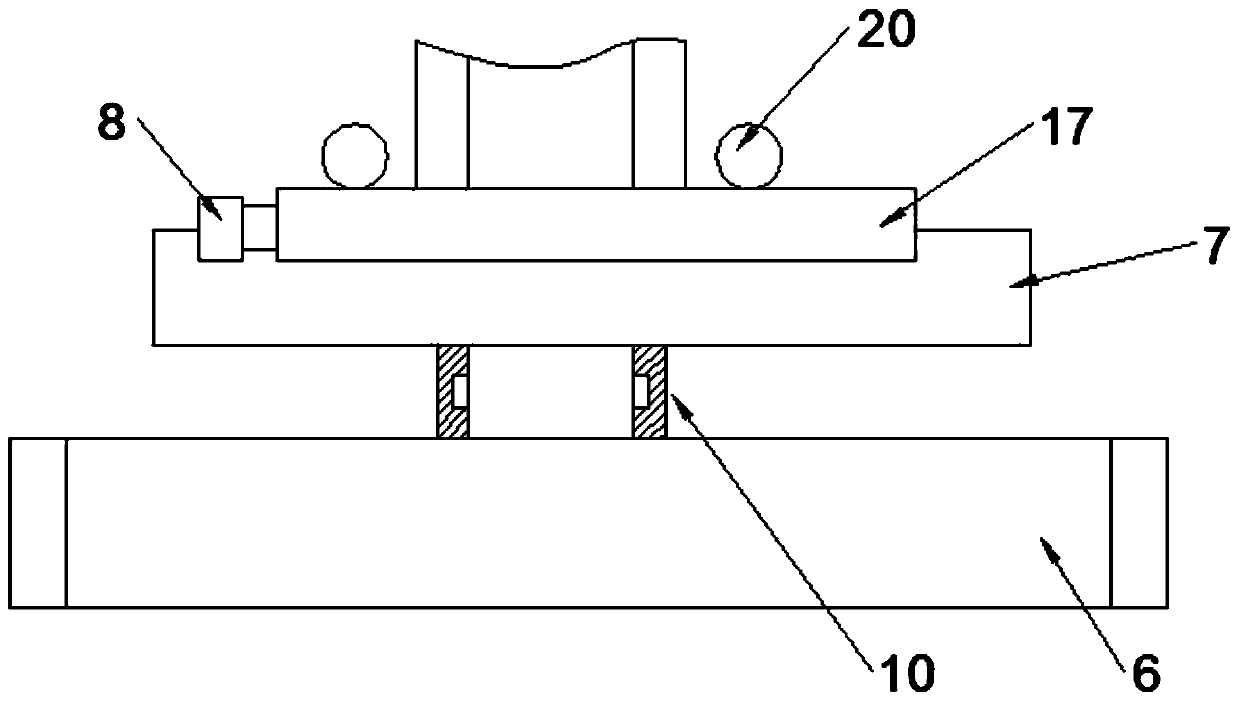

[0019] to combine Figure 1 to Figure 3 The shown hatch door structure of a front flap of a passenger car, in this embodiment, includes a hatch body 1, a mounting frame 2, a fixed frame 3, a fixed shaft 4, an arc block 5, an external gear 6, and a positioning ring 7 and insert block 8, the fixed shaft 4 is fixedly installed on one side of the mounting frame 2 through the fixed frame 3, and one side of the cabin door body 1 is provided with a rotary sleeve 9, and the rotary sleeve 9 is sleeved and connected to the fixed shaft 4, and the cabin The door body 1 can rotate around the fixed shaft 4 through the rotary sleeve 9. The arc block 5 is fixedly arranged on the side of the rotary sleeve 9 away from the fixed frame 3. The arc axis of the arc block 5 is collinear with the axis of the fixed shaft. And the arc surface of the arc-shaped block 5 is provided with a rack meshed with the external gear 6, and one side of the external gear 6 is also connected with the positioning ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com