Connector of light-emitting diode(LED) lamp strip

A technology of LED light strips and connectors, which is applied to the semiconductor devices of light-emitting elements, components of lighting devices, lighting devices, etc. Prevent loosening and facilitate plug-in and fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

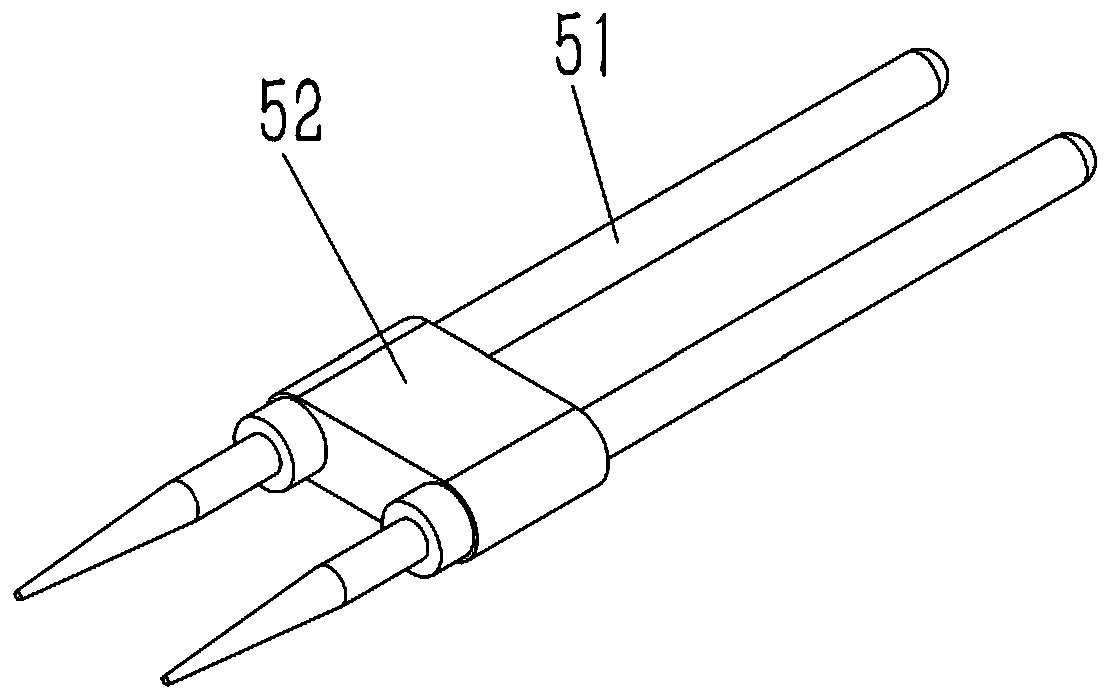

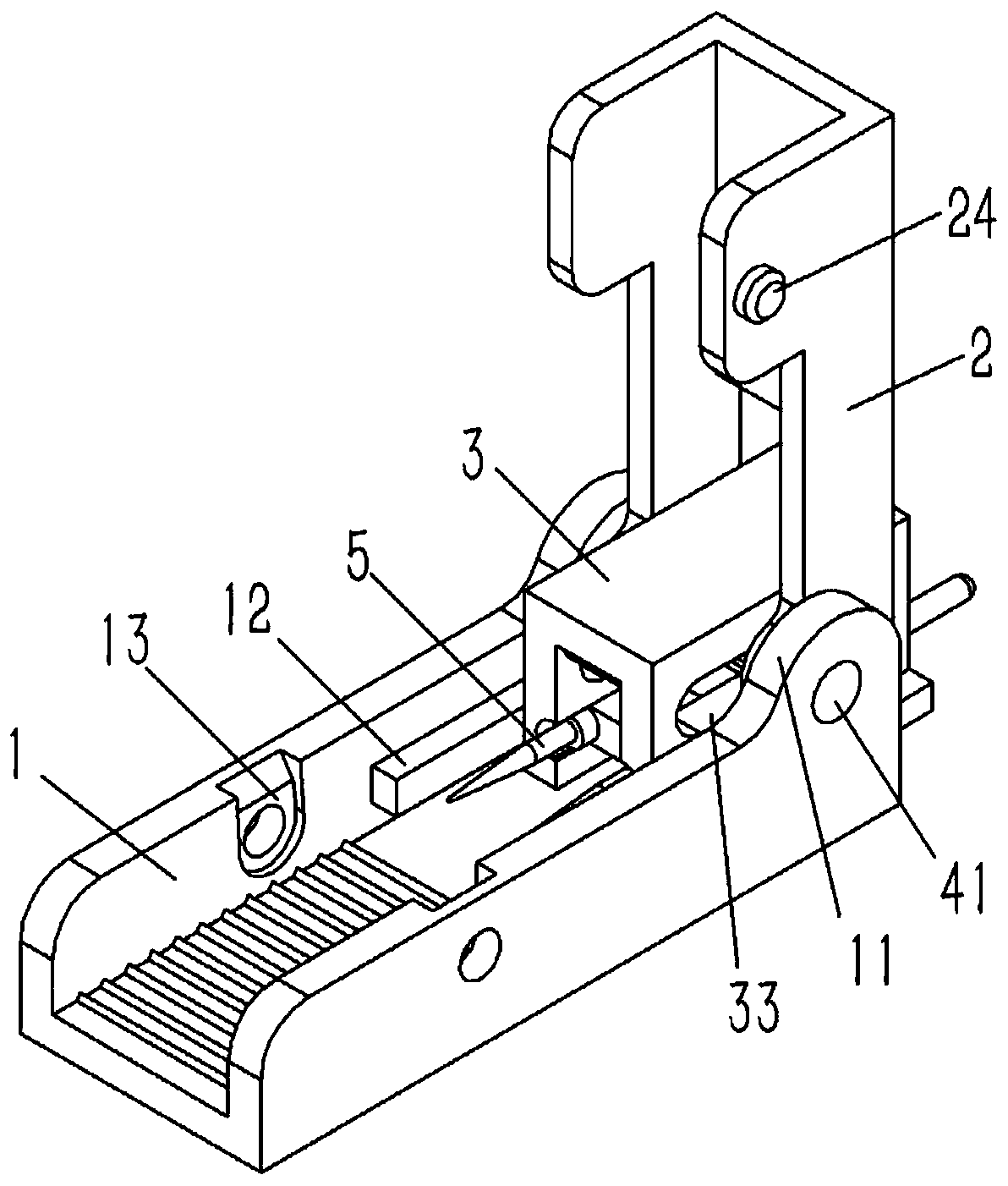

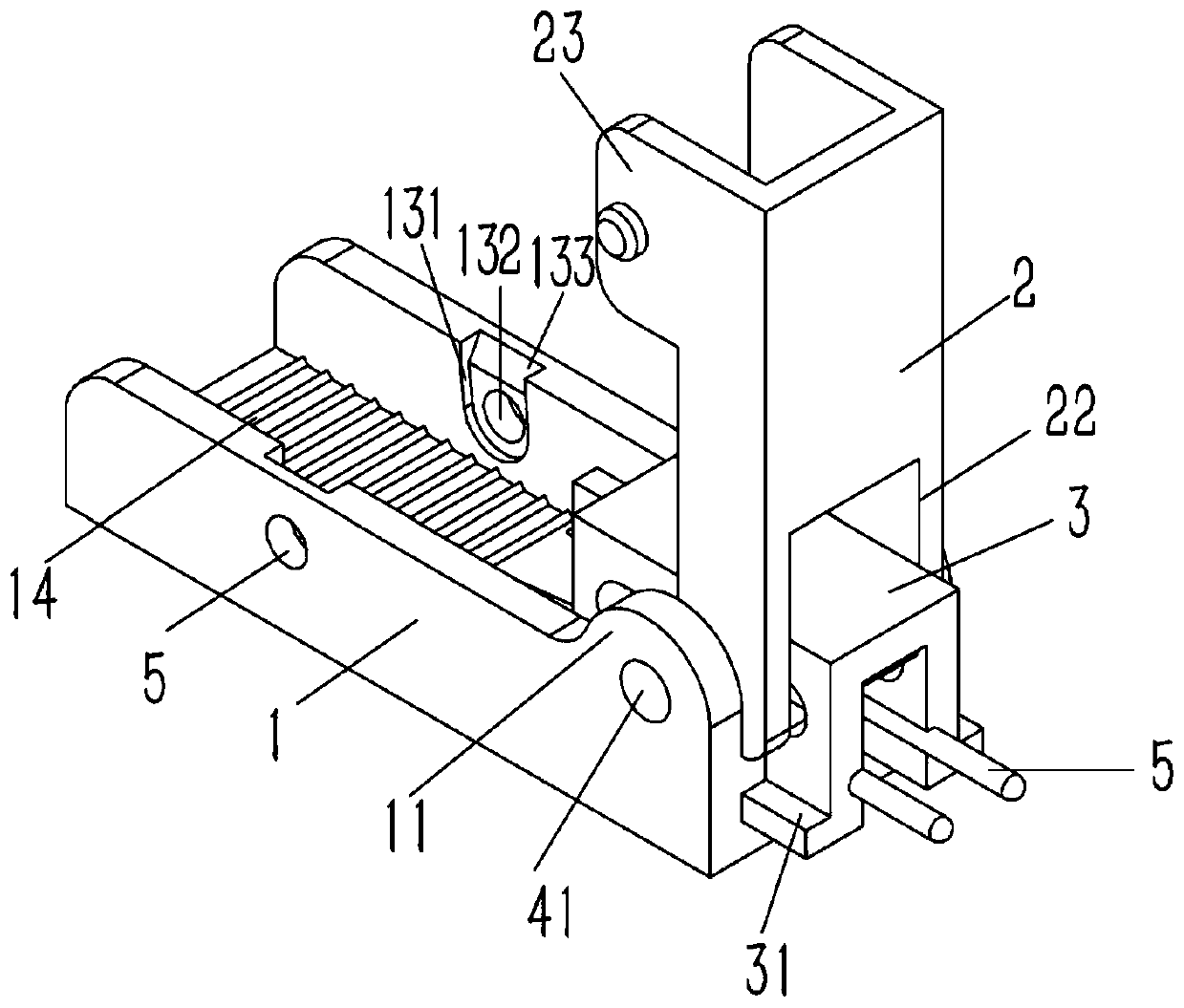

[0021] Example: see Figures 2 to 5 As shown in the figure, a connector for an LED light strip includes a "凵"-shaped slot seat 1 and a "冂"-shaped slot cover 2, the slot cover 2 is inserted in the slot seat 1, and the front end side wall of the slot cover 2 An upper lug 21 is formed, a semicircular lower lug 11 is formed on the side wall of the front end of the groove seat 1, and a horizontal bar 12 is formed on the inner side wall of the groove seat 1 below the lower lug 11; The groove seat 1 is inserted with a sliding seat 3 in the shape of "冂", the two sides of the lower end of the sliding seat 3 are formed with guide strips 31, and the guide strips 31 are inserted between the retaining strip 12 and the inner bottom surface of the groove seat 1; A rack 32 is formed on the bottom surface of the inner side of the sliding seat 3, and a horizontal guide groove 33 is formed on the side wall of the sliding seat 3 on the lower side of the rack 32. The gear shaft 4 is engaged with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com