Flexible tubular structure

A structure and modification technology, applied in the field of structured flexible pipes, structural hollow structures, hollow structures, and structural pipes, can solve problems such as leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

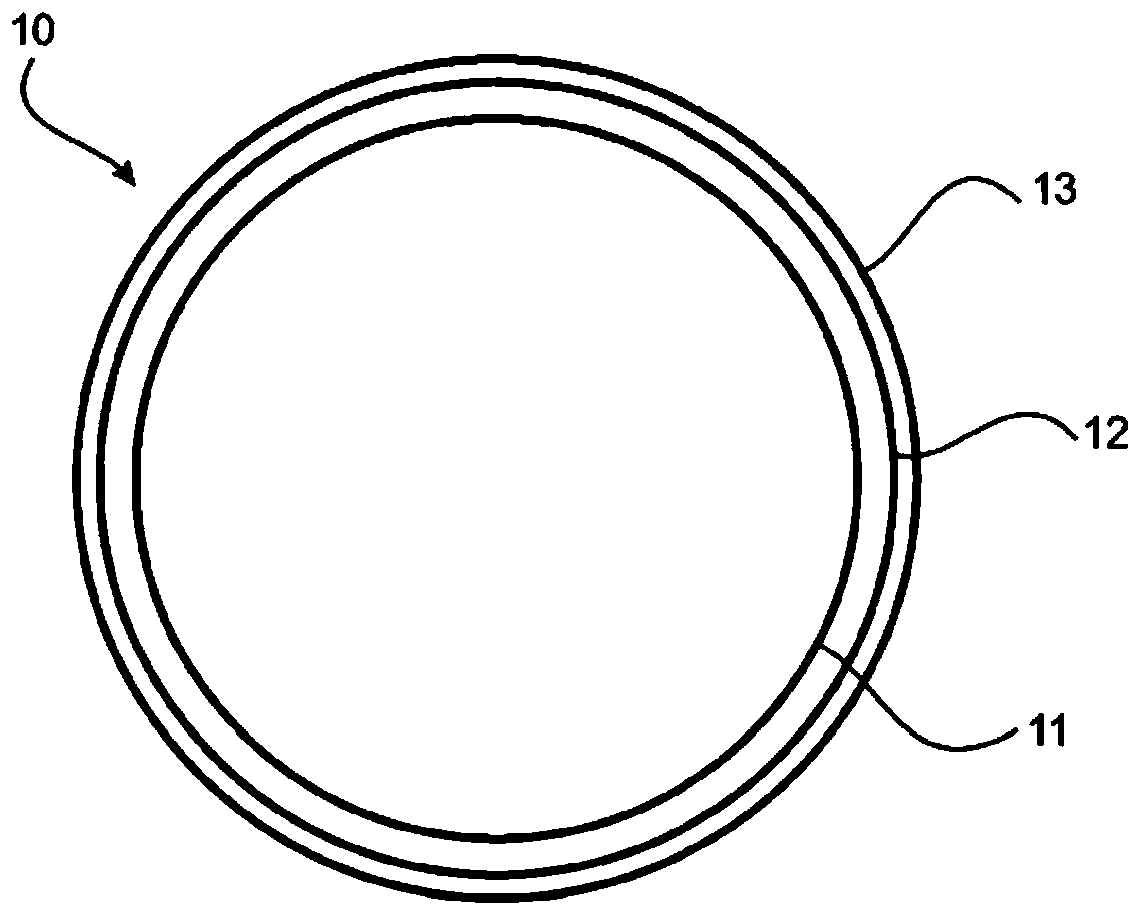

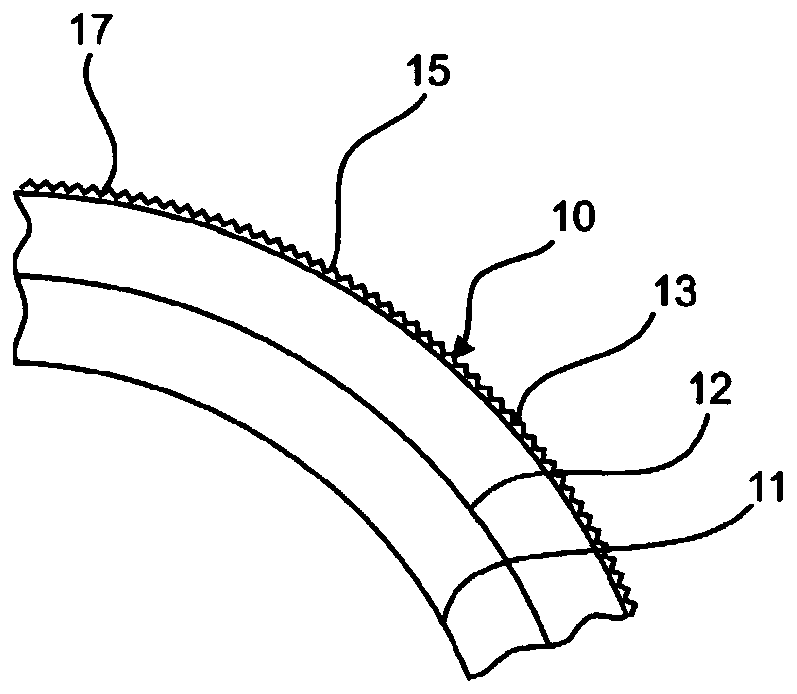

[0098] see Figure 1 to Figure 3 , shows a first embodiment of a tube 10 according to the invention in the form of a composite film structure and comprising a coextrusion of multiple layers bonded together to provide a one-piece structure. In the arrangement shown, there are three layers including an inner layer 11 , a middle layer 12 and an outer layer 13 .

[0099] The tube 10 is flexible in the sense that, after the tube 10 is constructed, the tube 10 can be presented in a compact state for storage and transportation. For example, the tube can assume a "flat-folded" state in which the tube collapses upon itself. The tube may be rolled into a roll to assume a compact condition, preferably in a "flat folded" condition. Additionally or alternatively, the tube may be sectionally folded back and forth on itself at intervals along its length to assume a compact condition, preferably in a "flat folded" condition.

[0100] In other embodiments, more than one intermediate layer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com