High-efficiency automatic magnetism protecting ring assembling machine

A high-efficiency, assembly machine technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low cost, low efficiency of manual assembly, high product cost, etc., and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0021] Figure 6 It is the guard magnetic ring when assembled in the present invention, and the guard magnetic ring is a hollow thin-walled structure. The guard magnetic ring is composed of two opposite side planes and two opposite side arc surfaces. A notch penetrating the side is arranged axially on one side circular arc surface, and a groove is provided at the middle of one end outside the other said circular arc side, and the bottom of the groove protrudes inside the magnetic guard ring. For the schematic diagram of the assembly of the magnetic ring and the motor, see Figure 7 .

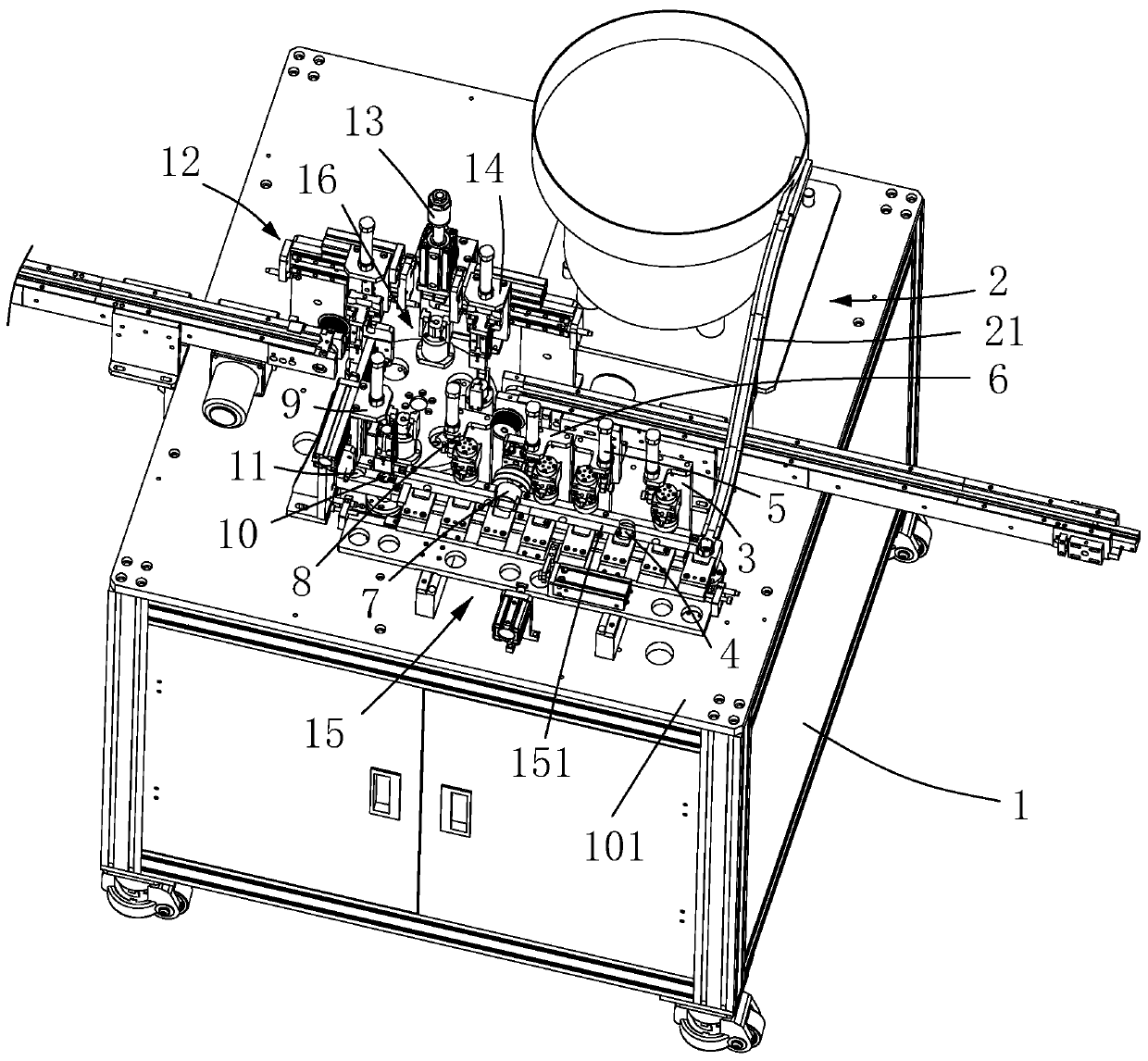

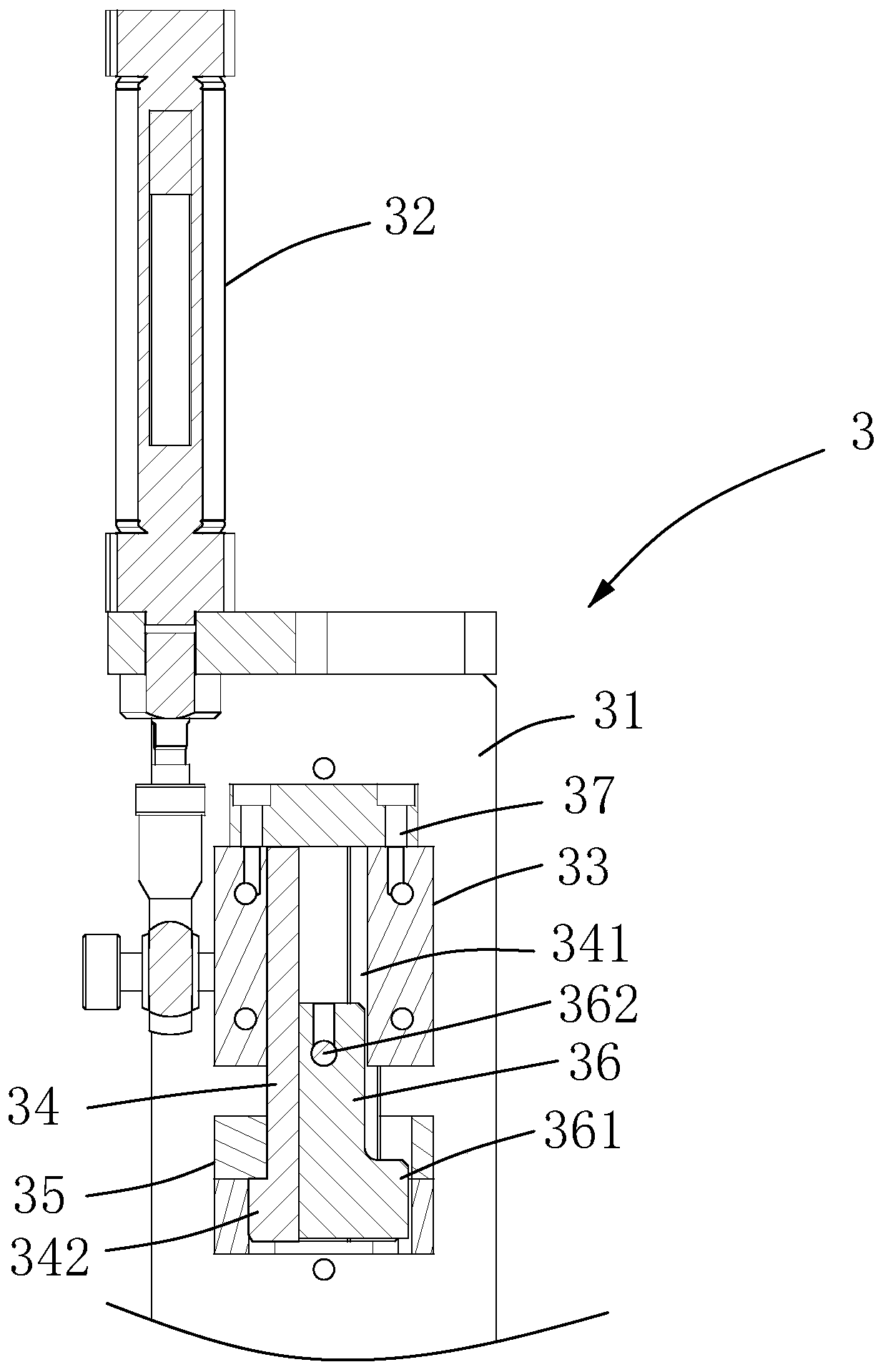

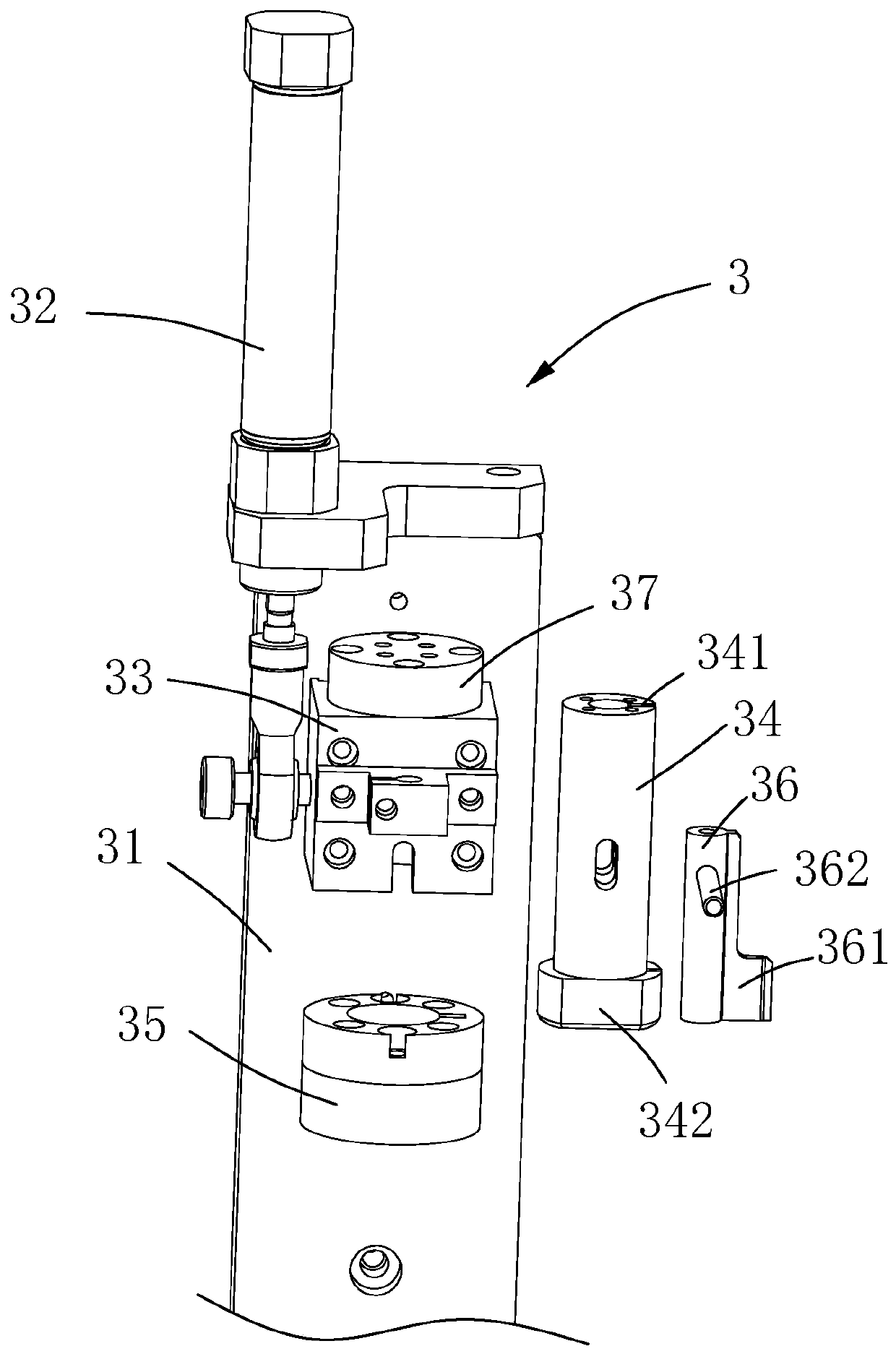

[0022] figure 1 It is a high-efficiency automatic magnetic coil assembling machine, which includes a rectangular parallelepiped frame 1 . Four corners of the lower end of the frame 1 are respectively connected with rollers to facilitate the movement and adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com