Auxiliary base for telegraph pole installation

A utility pole and installation technology, applied in the field of auxiliary bases for utility pole installation, can solve problems such as ground damage, safety accidents, hidden dangers in the normal use of utility poles, etc., and achieve the effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

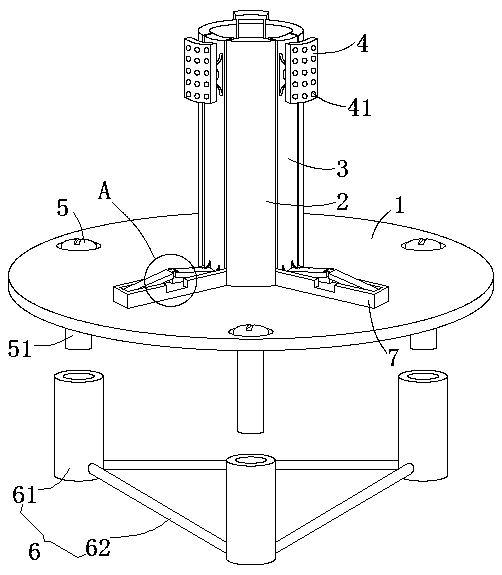

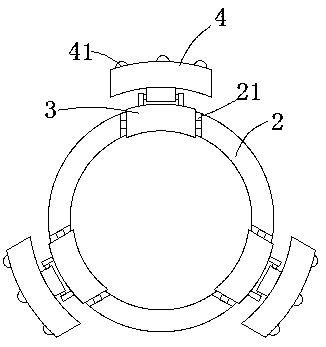

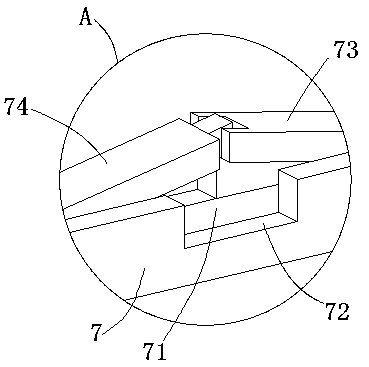

[0026] see Figure 1-5 , this embodiment provides an auxiliary base for installation of utility poles, including a base 1 and a positioning sleeve 2, the positioning sleeve 2 is welded vertically at the center of the top end surface of the base 1, and the axial side of the positioning sleeve 2 The wall is provided with three positioning notches 21 evenly spaced apart, and the inner cavity of each positioning notch 21 is rotated by a pin shaft to be provided with a hinge plate 3 that can rotate between the middle positions of the left and right side walls of the inner cavity of each positioning notch 21, The top of the side wall of each hinge plate 3 away from the center of the inner cavity of the positioning sleeve 2 is hinged with a fitting plate 4 that can swing up and down around the hinge point, and the swing range is between 0 and 30 degrees, and the positioning sleeve 2 The bottom of the outer wall of the outer wall is radially provided with positioning plates 7 facing t...

Embodiment 2

[0032] see Figure 1-5 , further improvements have been made on the basis of Example 1:

[0033] The side wall of each bonding plate 4 away from the hinge plate 3 has several convex points 41 distributed uniformly in a rectangular shape, and the bonding resistance to the side wall of the utility pole cavity is enhanced by setting the convex points 41 .

[0034] Every first articulated rod 74 is equal to the height of every second articulated rod 73, and is 1 / 3rd of the inner chamber vertical height of each placement breach 71, by connecting each first articulated rod 74 with each The height of the second articulated rod 73 is equal, and is one-third of the vertical height of the inner cavity of each notch 71, so that after the utility pole is pressed together with the first articulated rod 74 and the second articulated rod 73, it can still be locked. Closed in the inner cavity of the rectangular clamping gap 72, the phenomenon of displacement of the bottom end of the utility po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com