Heat dissipation method of pluggable board card which adopts a heat conduction film

A heat dissipation method and heat conduction film technology, applied in the direction of instruments, electrical digital data processing, digital data processing components, etc., can solve the problems of easy fluctuation of temperature control curve, insufficient heat conduction, poor temperature control effect, etc., to avoid partial The effect of high temperature, improved heat transfer efficiency, and shortened service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

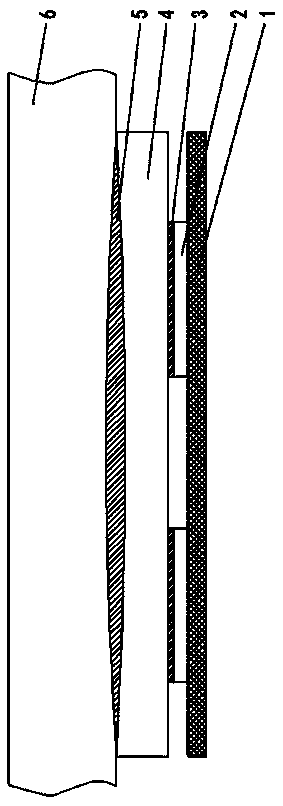

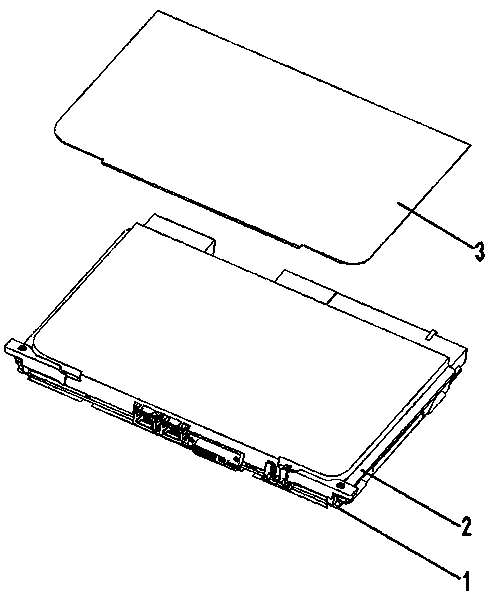

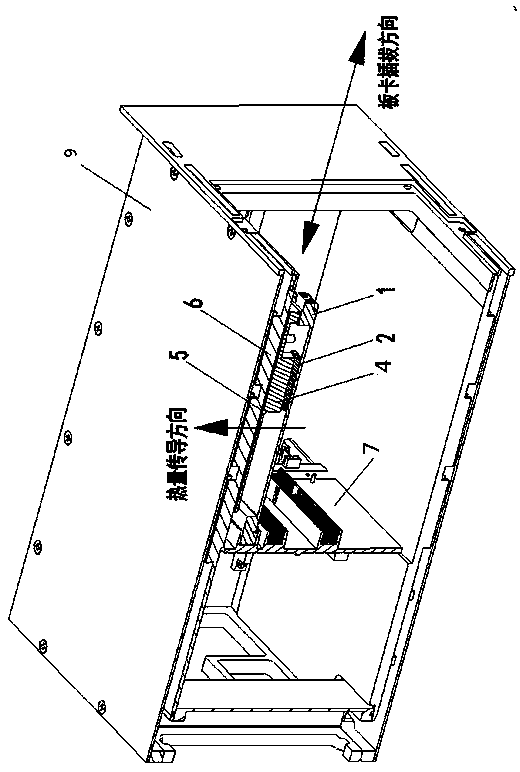

[0036] A heat dissipation method for a pluggable board card using a heat conduction film, the specific method is as follows:

[0037] Use non-woven cloth soaked in organic cleaning agent to wipe and clean the upper surface of heating element 2 and the lower surface of cold plate 4 to ensure that there are no impurities on the contact surface of heating element 2 and cold plate 4; wherein the heating element is CPU and other Heating components; the organic cleaning agent is absolute ethanol or acetone.

[0038] Use a clean scraper to evenly coat the upper surface of the heating element 2 with the thermally conductive silicone grease 3, and place the cold plate 4 on the upper surface of the heating element 2; the thickness of the thermally conductive silicone grease 3 is 0.05mm-0.1mm.

[0039] Wipe and clean the upper surface of the cold plate 4 with a non-woven cloth soaked in an organic cleaning agent to ensure that there is no impurity on the contact surface between the cold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com