Foundation pit supporting composite retaining wall and construction method thereof

A composite retaining wall and foundation pit support technology, which can be used in infrastructure engineering, excavation, artificial islands, etc., can solve the problems of a large number of concrete piles, increased construction costs, and long construction period of concrete piles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

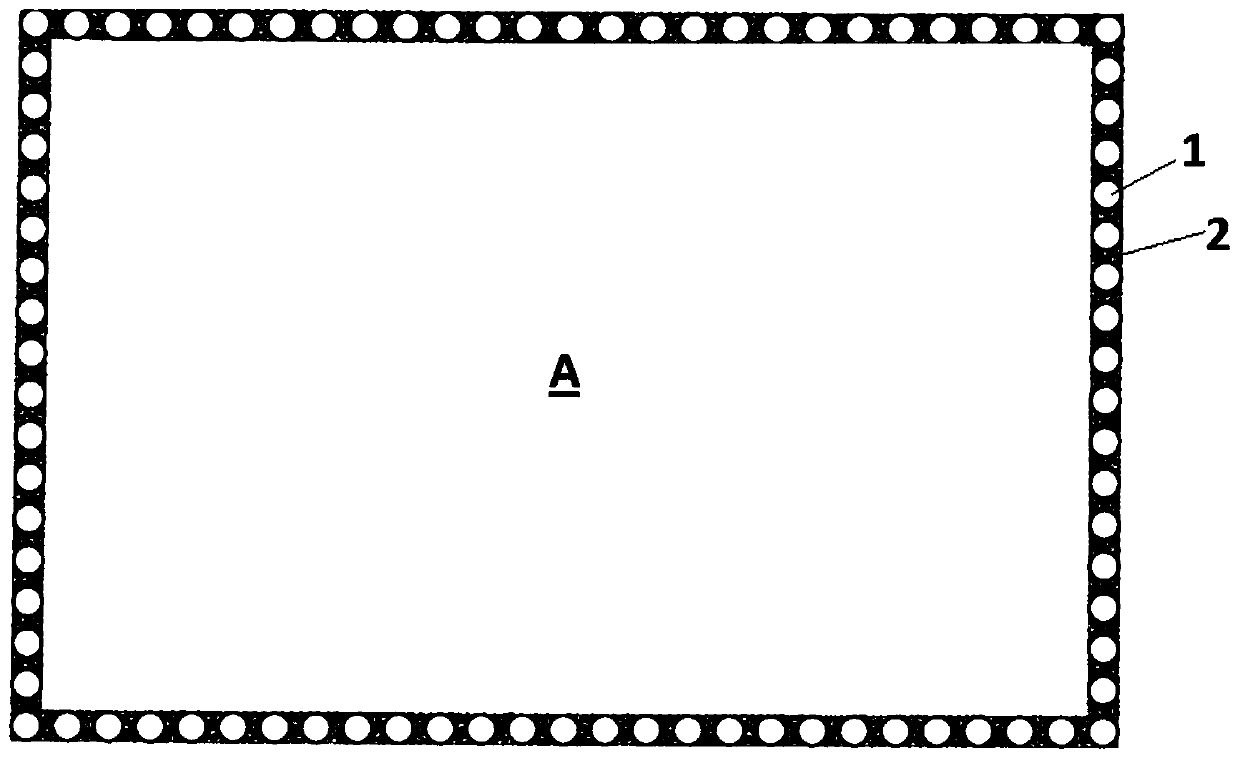

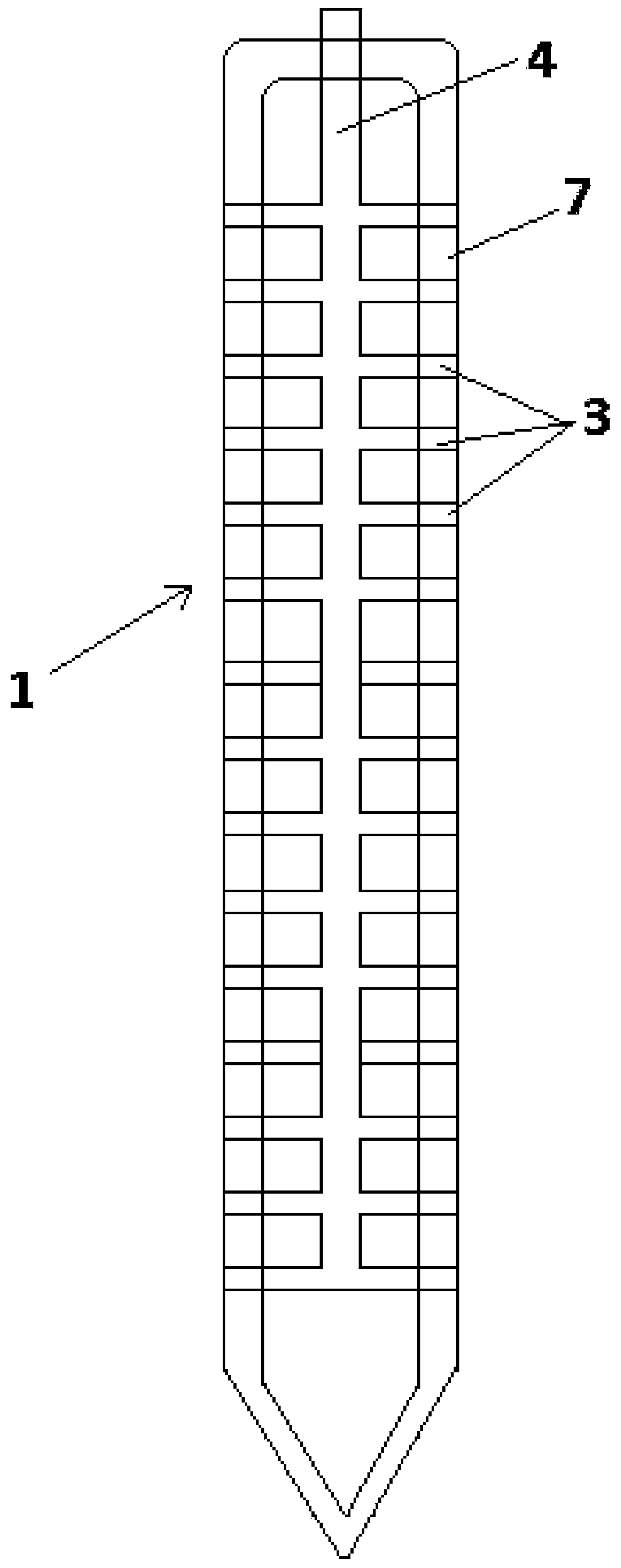

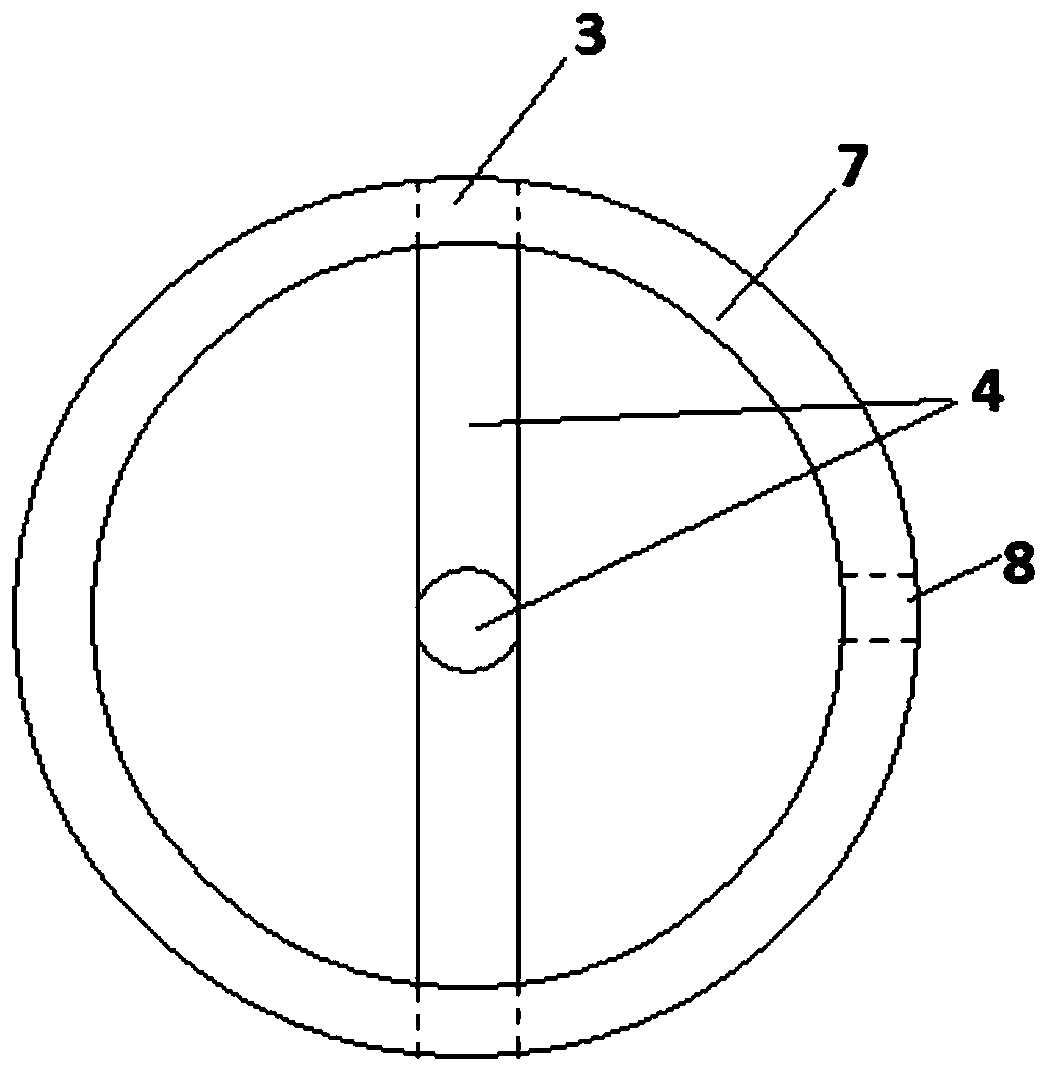

[0037] Such as figure 1 As shown, the foundation pit support composite retaining wall provided in this embodiment includes: several tubular piles 1 with hollow structures arranged in the circumferential direction; the connecting structure 2 is connected with two adjacent tubular piles 1 to form A circumferentially closed retaining wall; wherein, at least one of the pipe walls at the lower part of the pipe pile is provided with a water pump facing the inner side of the foundation pit A and communicating with the inner soil body of the foundation pit and the hollow structure structure, and the pumping structure is suitable for introducing groundwater inside the foundation pit into the hollow structure of the pipe pile. The connection structure 2 may be a cement-soil retaining wall part, located between two adjacent pipe piles, and connected with the pipe piles; Corresponding grouting structure. Such as figure 2 As shown, the pipe pile can be open at the upper end and sealed ...

Embodiment 2

[0043] The present invention also provides a construction method for foundation pit supporting composite retaining wall, such as Figure 6 - Figure 8 As shown, it includes: a. Using a piling device to insert several pipe piles with a hollow structure into the soil at the pile positions arranged in the circumferential direction until a predetermined depth, wherein, such as Figure 6 As shown, the pipe wall of the pipe pile is provided with a grouting structure corresponding to the part of the cement-soil retaining wall; at least one pipe wall at the lower part of the pipe pile 1 is provided with a , and a pumping structure connected with the inner soil body of the foundation pit A and the hollow structure, suitable for introducing groundwater located inside the foundation pit into the hollow structure of the pipe pile; b. using grouting The equipment injects cement slurry 12 into the soil through the grouting structure to form a cement-soil structure connected to the pipe pil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com