Ultrasonic-knife conduction rod and ultrasonic knife

An ultrasonic knife and transmission rod technology, applied in the field of ultrasonic surgical knives, can solve the problems of sacrificing the resonance phase tolerance, increasing the input ultrasonic wave of the knife rod, and unstable sound wave conduction, achieving reasonable sound gain, realizing acoustic characteristics, and good vibration shape. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are part of the embodiments of the present invention, not all of them.

[0037] Elements / components with the same or similar numbers used in the drawings and embodiments are used to represent the same or similar parts. And the drawings are only schematic, and the elements therein need not be in proportion.

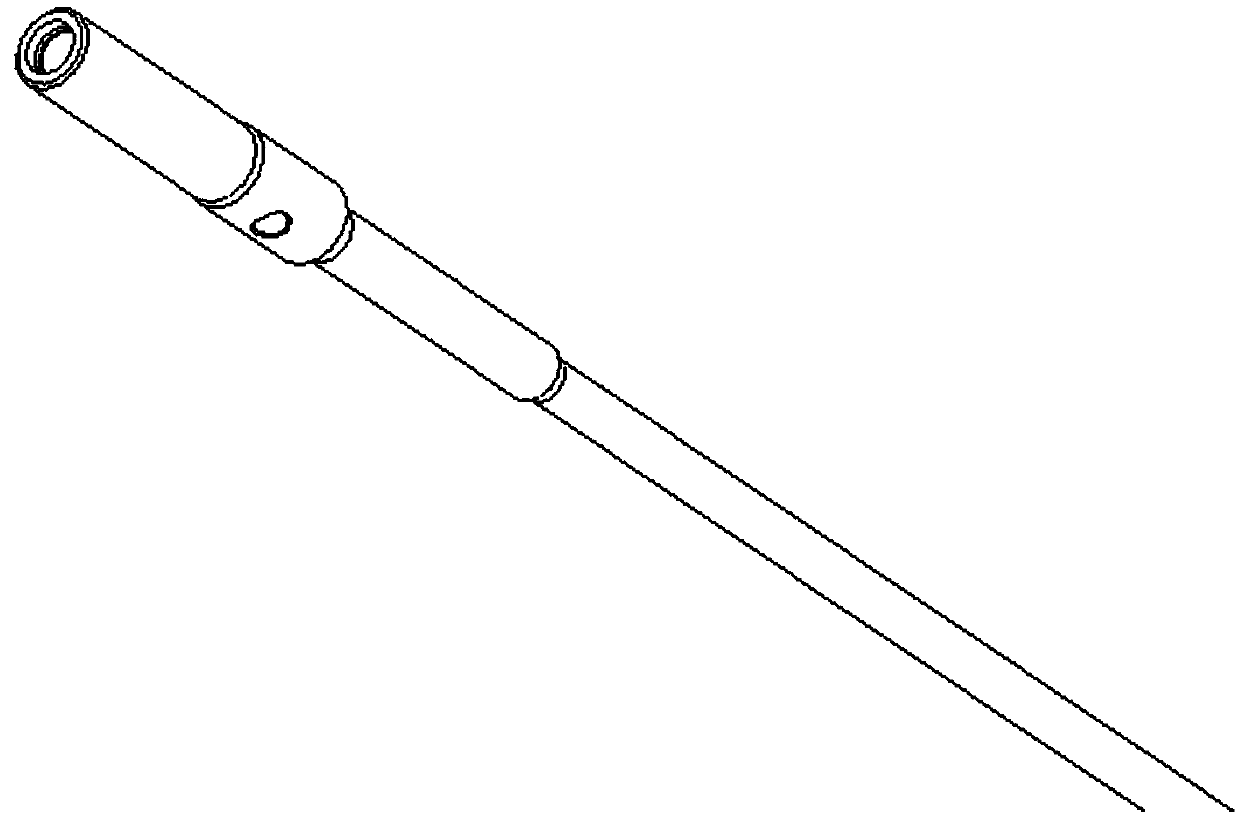

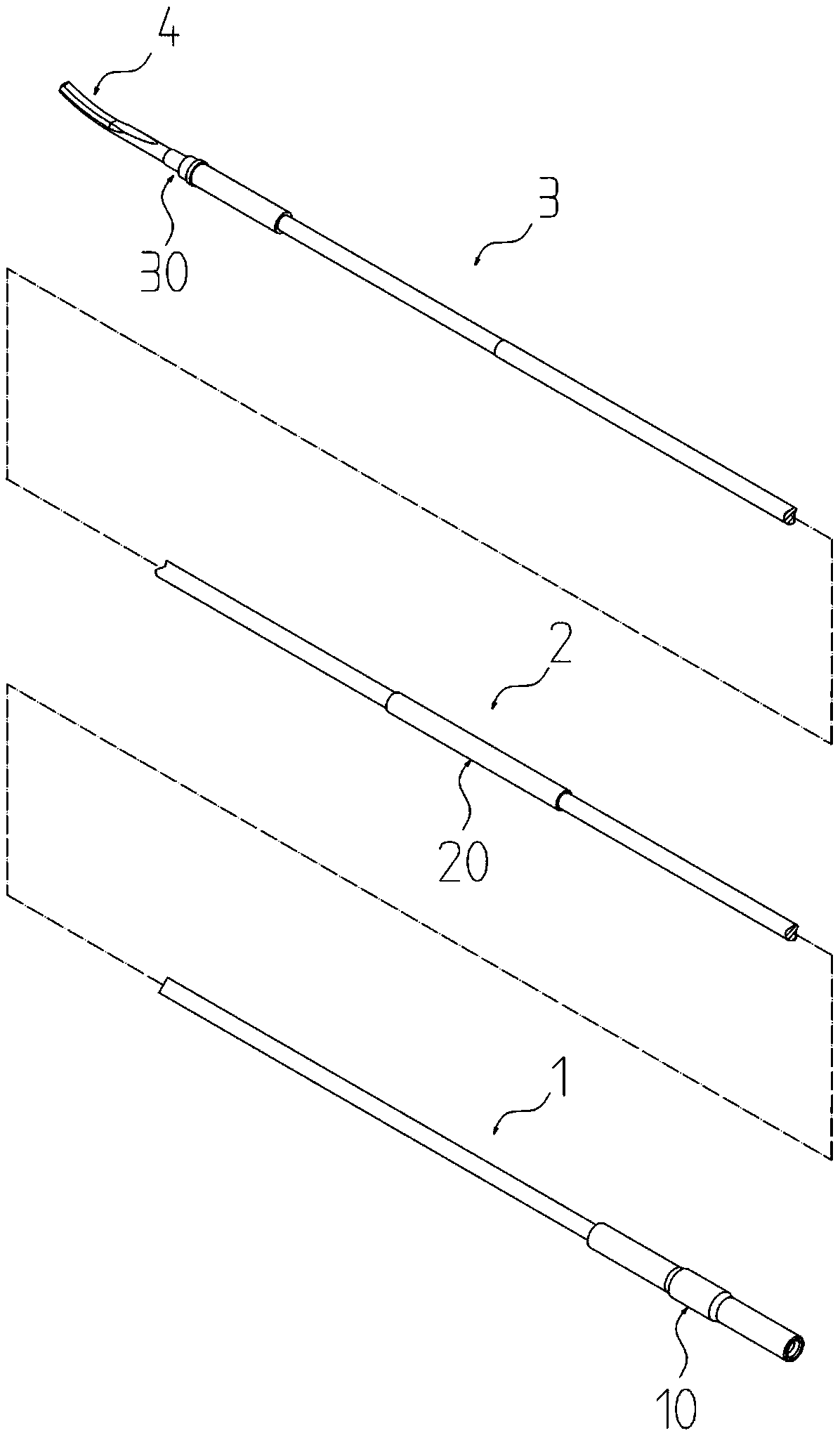

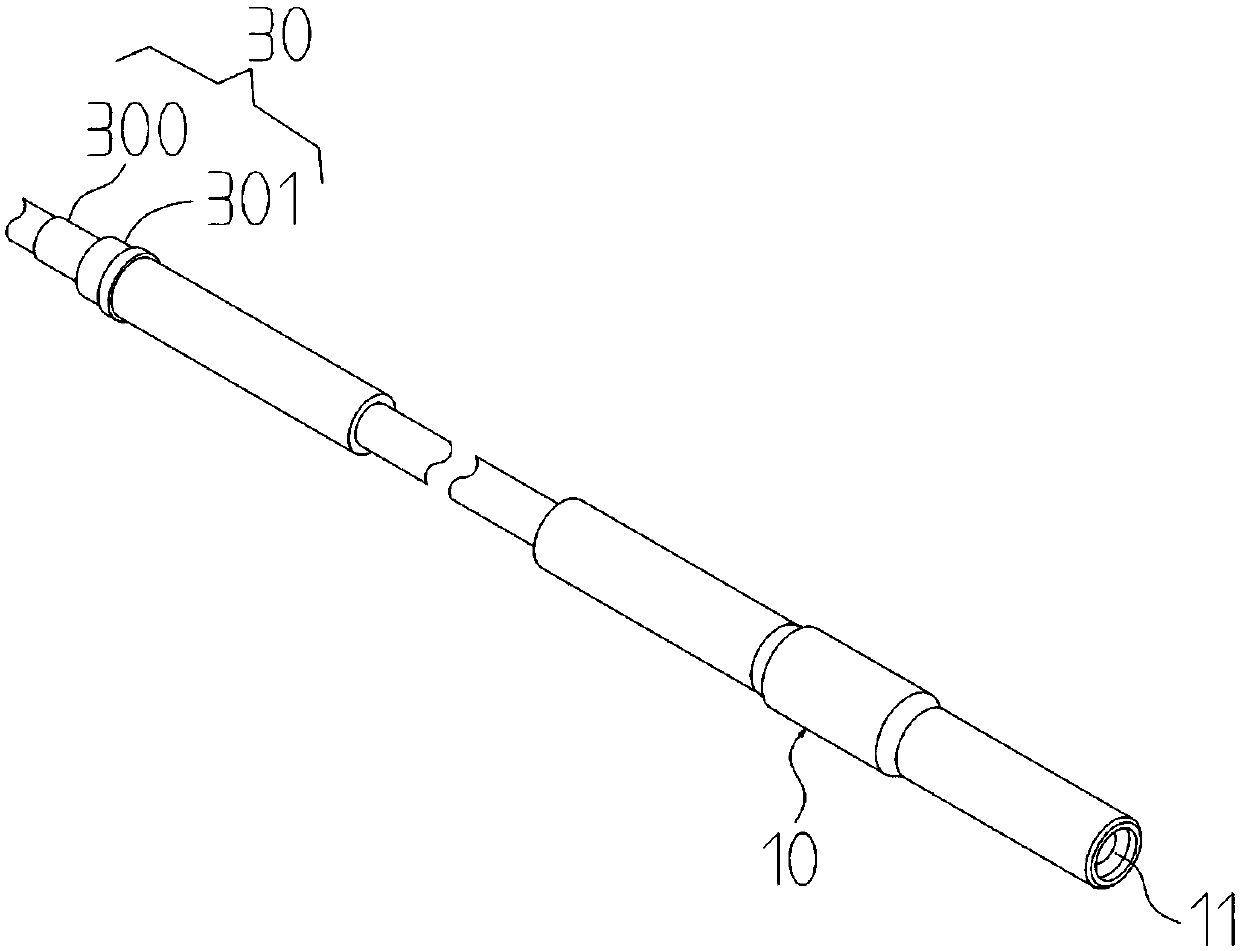

[0038] figure 2 Illustrates an exploded structural schematic diagram of the entire ultrasonic knife conductive rod according to an embodiment of the present invention. Such as figure 2 As shown, the conductive rod of the ultrasonic knife of the embodiment of the present invention includes a proximal rod 1, a middle rod 2 and a distal rod 3 that are connected in sequence. One end of the proximal rod 1 is connected to the ultrasonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com