A kind of immersion type cleaning method for quartz furnace tube

A technology for quartz furnaces and furnace tubes, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of easily damaged quartz furnace tubes, achieve small movement range, reduce the risk of damage, Simple action mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

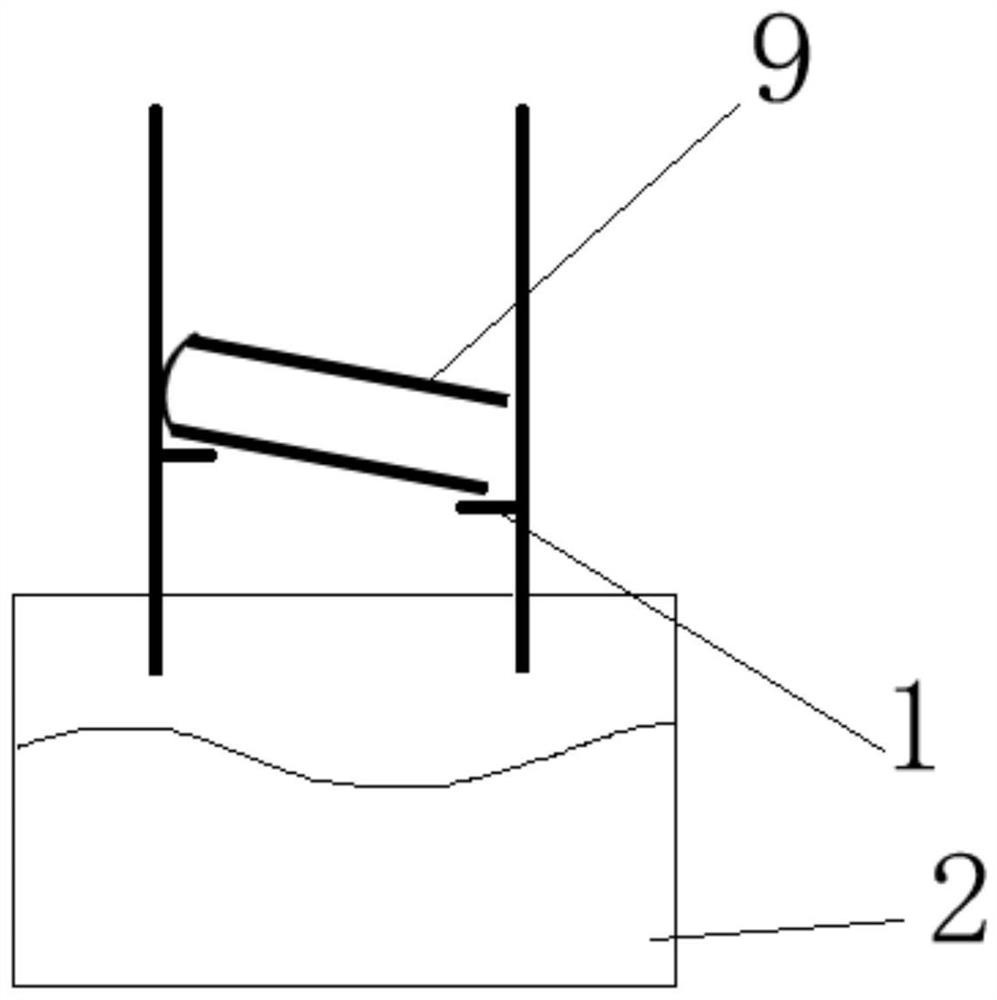

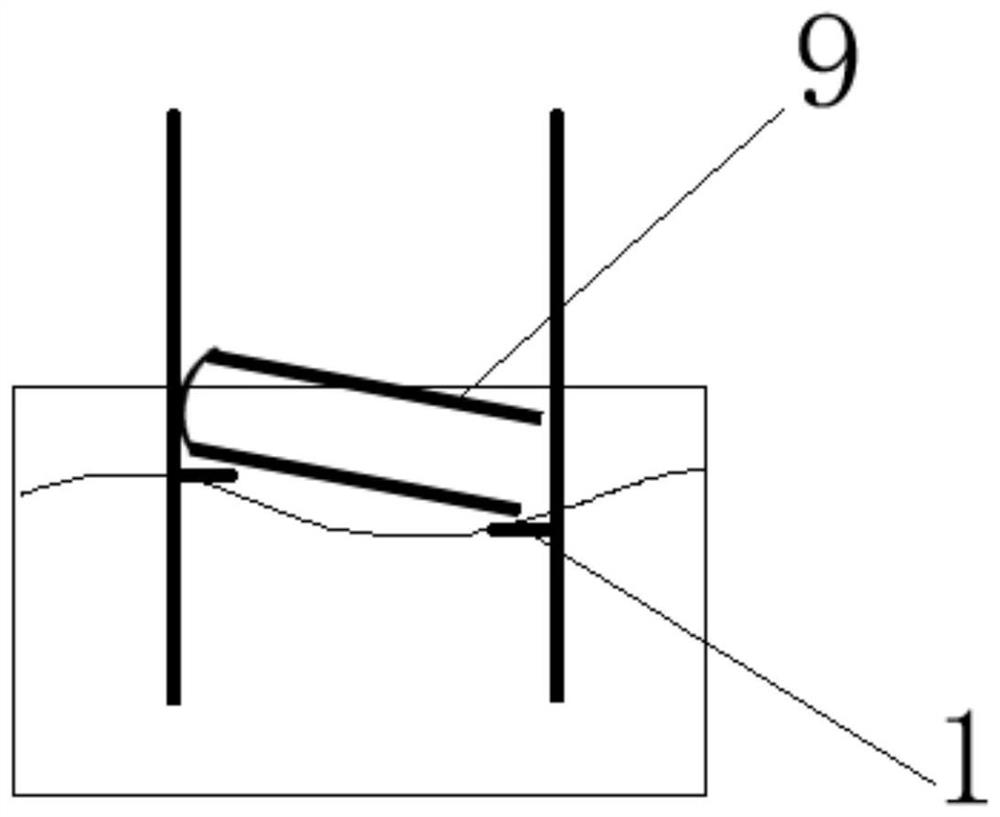

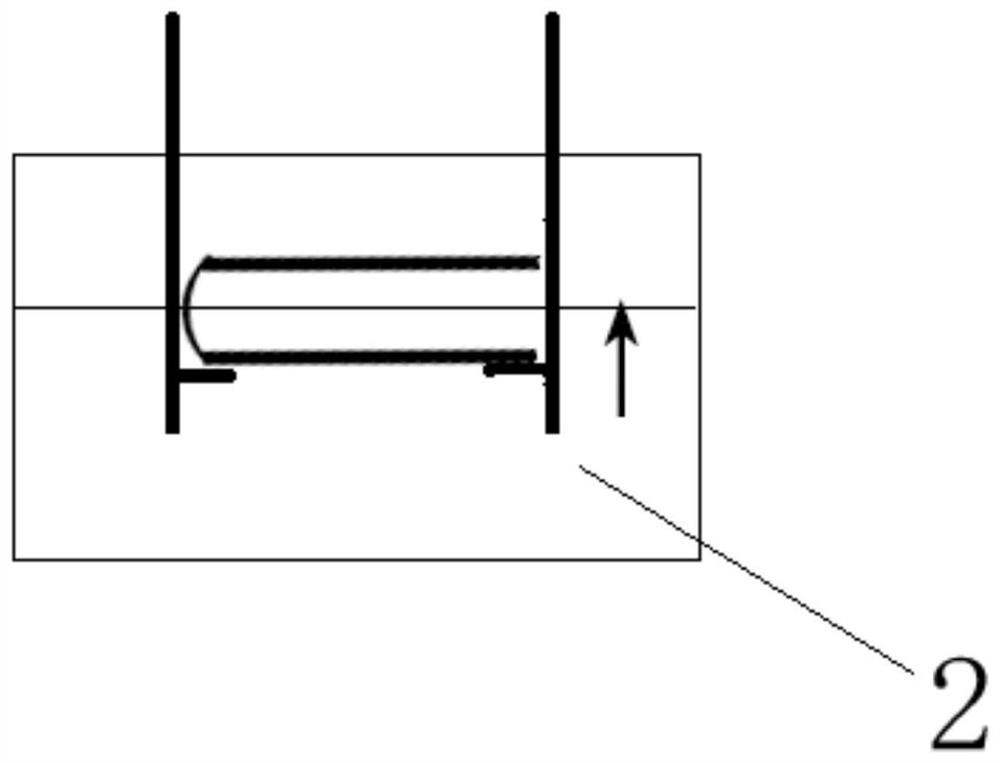

[0039] This embodiment provides a quartz furnace tube immersion cleaning method, comprising the following steps:

[0040] S1: Place the quartz furnace tube to be cleaned on the fixed arms located on both sides of the quartz furnace tube with a height difference, and make the opening of the quartz furnace tube face down. The angle between the central axis of the quartz furnace tube and the horizontal plane is 20 -30°, such as: 20°, 25°, 30°; in order to protect the quartz furnace tube, the fixed arm is provided with a corrosion-resistant silicone rubber pad;

[0041] S2: Make the quartz furnace tube move relative to the cleaning tank filled with cleaning liquid, make the quartz furnace tube close to the cleaning liquid in the cleaning tank, and adjust the fixed arms on both sides when the inner wall of the quartz furnace tube is in contact with the liquid surface of the cleaning liquid. Position, so that the opening of the quartz furnace tube gradually faces upwards. When the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com