Adjustable operation platform for production of computer integrated chips

An integrated chip and console technology, applied in the direction of worktables, manufacturing tools, etc., can solve the problems that the console cannot be disassembled and replaced, and the practical performance is not enough, so as to achieve the effect of ensuring installation efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

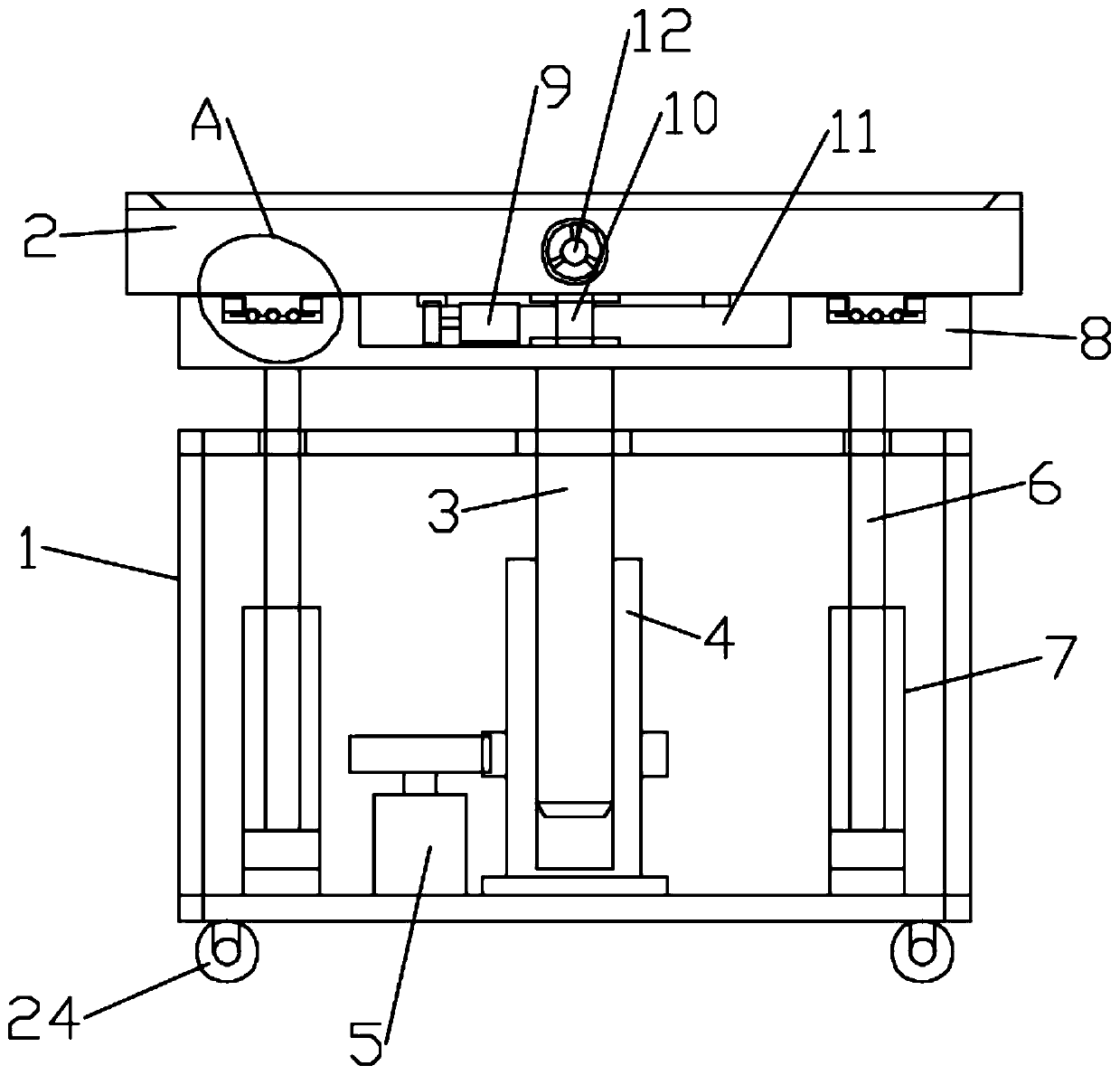

[0029] Such as Figure 1-5 As shown, in one embodiment provided by the present invention, an adjustable operating platform for computer integrated chip production includes a bottom box 1 and a height-adjustable support base 8 installed above the bottom box 1 , the support The turret on the seat 8 is provided with a support platform 2, and an operating platform 13 is installed on the support platform 2 in a detachable manner;

[0030] Specifically, in the embodiment provided by the present invention, the four corners of the bottom surface of the bottom box 1 are provided with supporting casters 24, so as to facilitate the movement of the whole device; , the top plate of the bottom box 1 is provided with a rotary screw 3 for rotation, and the rotary screw sleeve 4 is sleeved on the rotary screw 3 in the bottom box 1 through a threaded connection; the support seat 8 is along the central axis The bottom surface is rotatably mounted on the top of the outer rotating screw 3 of the ...

Embodiment 2

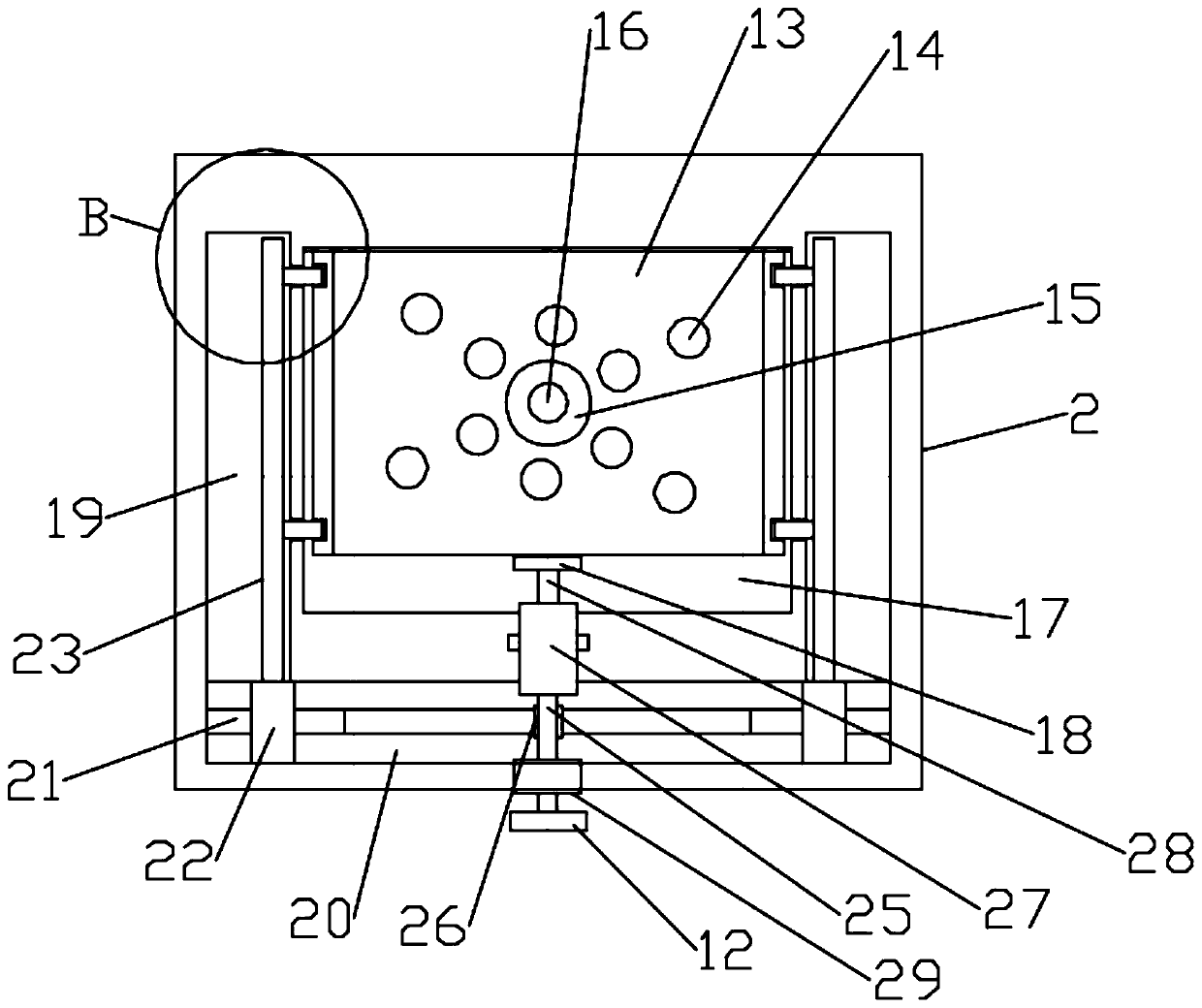

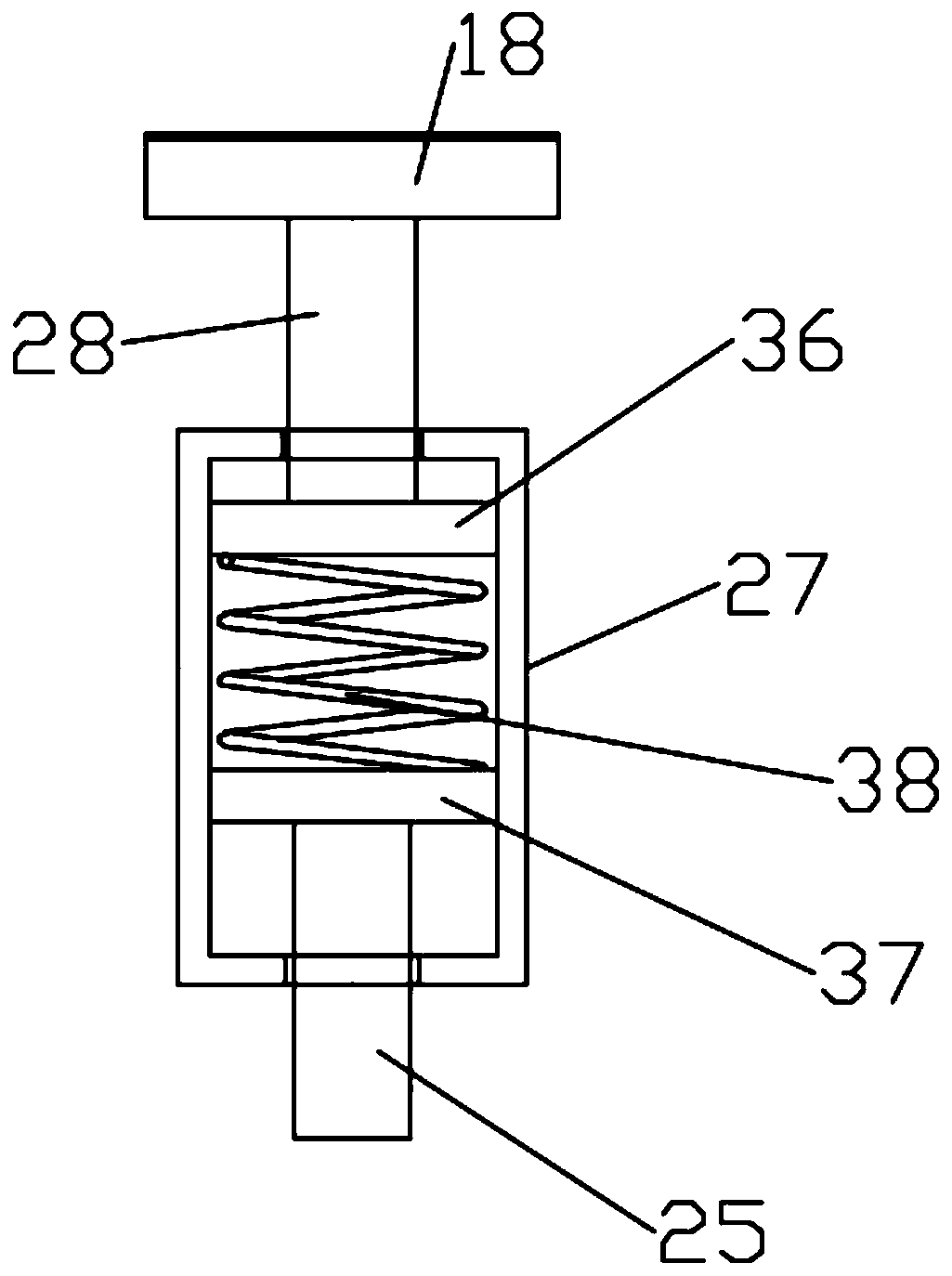

[0035] Such as figure 1 , figure 2 , image 3 and Figure 5 As shown, the difference from Embodiment 1 is that in the embodiment provided by the present invention, the top surface of the support table 2 has a mounting groove 17 for accommodating the operating table 13, and both sides of the mounting groove 17 have support cavity 19, and the top surface of the support table 2 also has an adjustment cavity 20 whose two ends communicate with the ends of the two support cavities 19 respectively, and an adjustment screw 21 is installed in the adjustment cavity 20, and the adjustment screw 21 is two The outer threads of the end outer rings have opposite directions of rotation, and the two adjusting screw sleeves 22 horizontally slid in the adjustment cavity 20 are respectively sleeved on the outer rings at both ends of the adjustment screw rod 21 through threaded connection. Both the adjusting screw sleeves 22 are fixedly equipped with adjusting pressing plates 23, and the two a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com