Suction device

A technology of adsorption device and adsorption part, which is applied in the direction of transportation and packaging, load hanging components, chucks, etc., can solve the problems of workpiece falling off and position deviation, and achieve the effect of preventing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

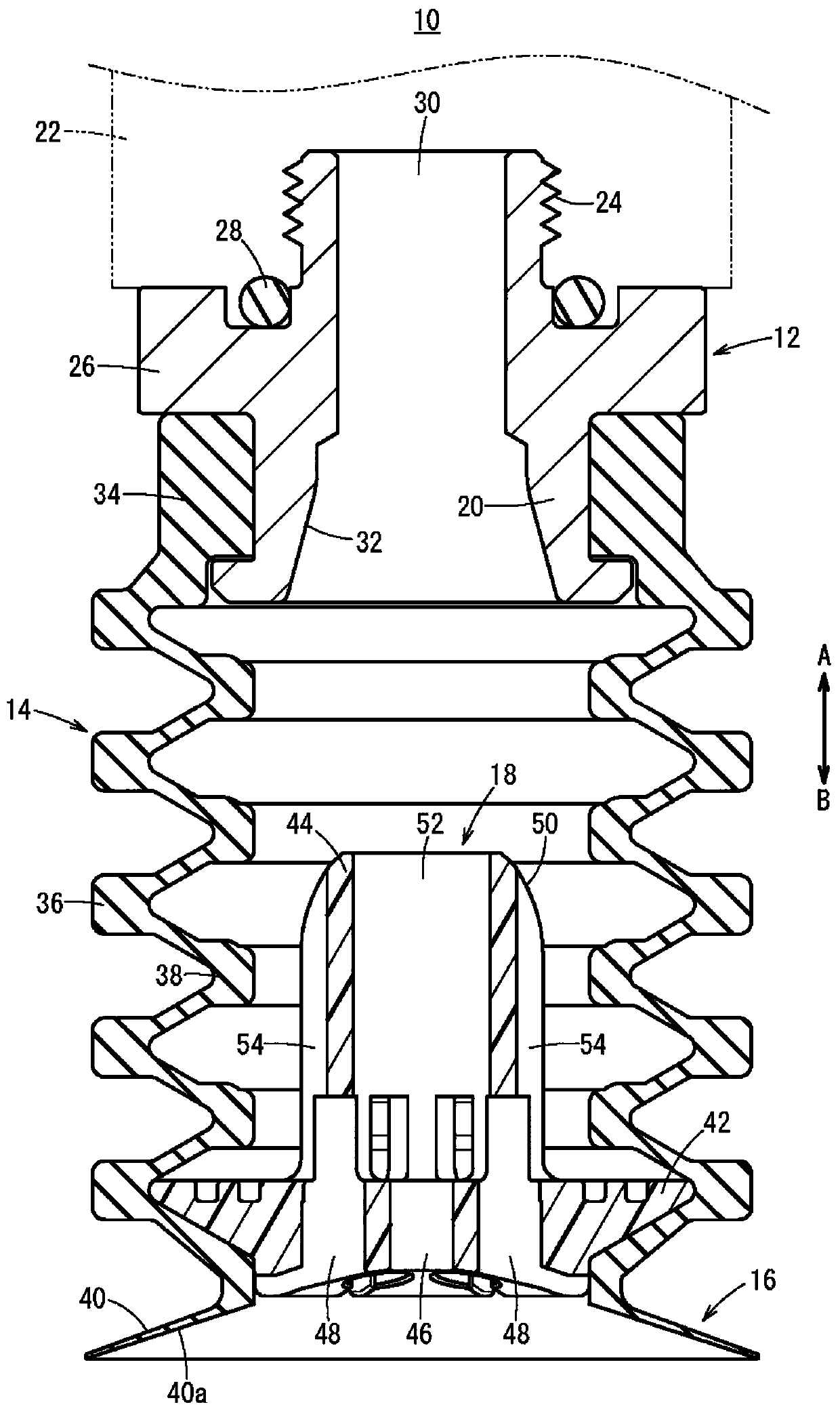

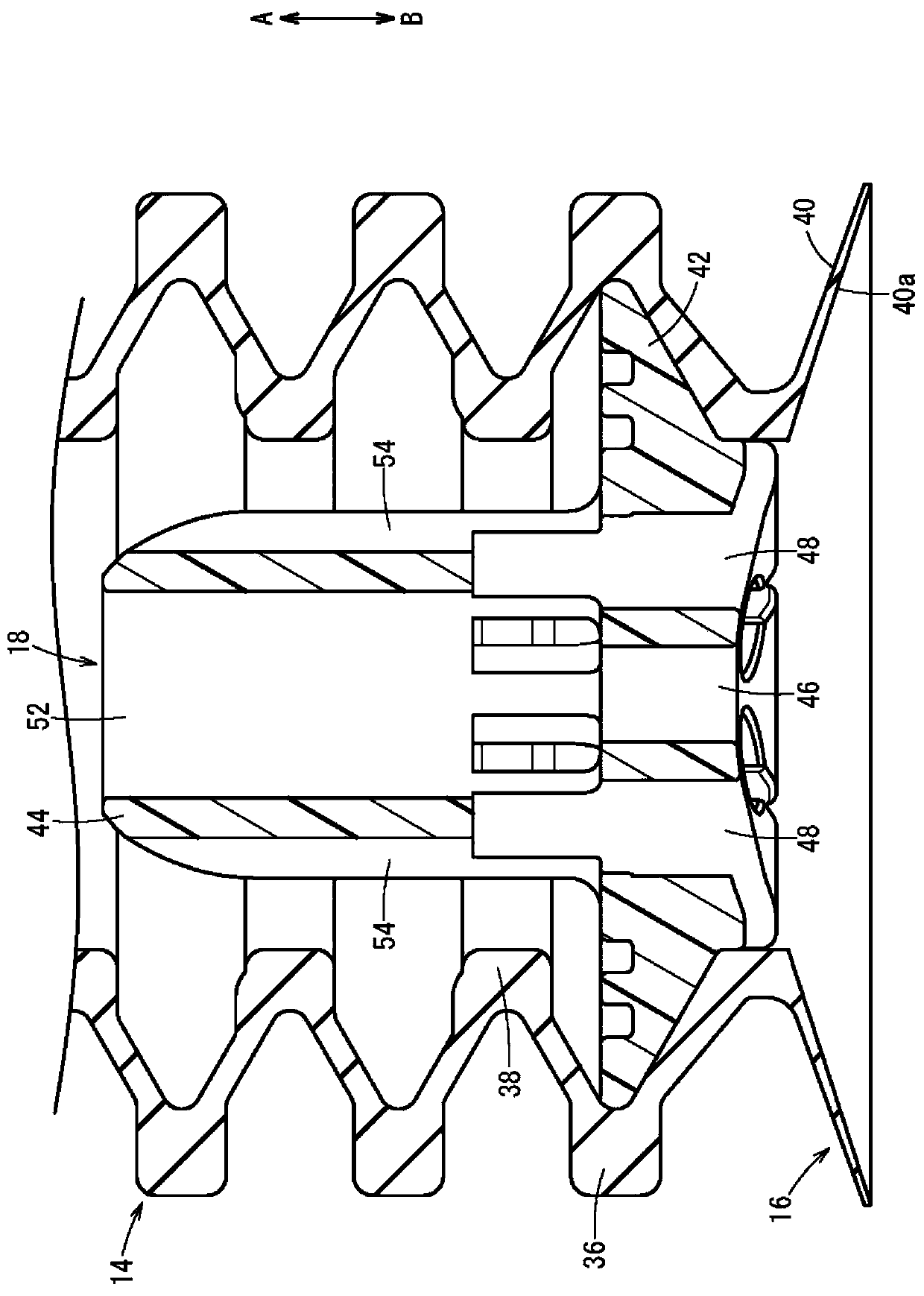

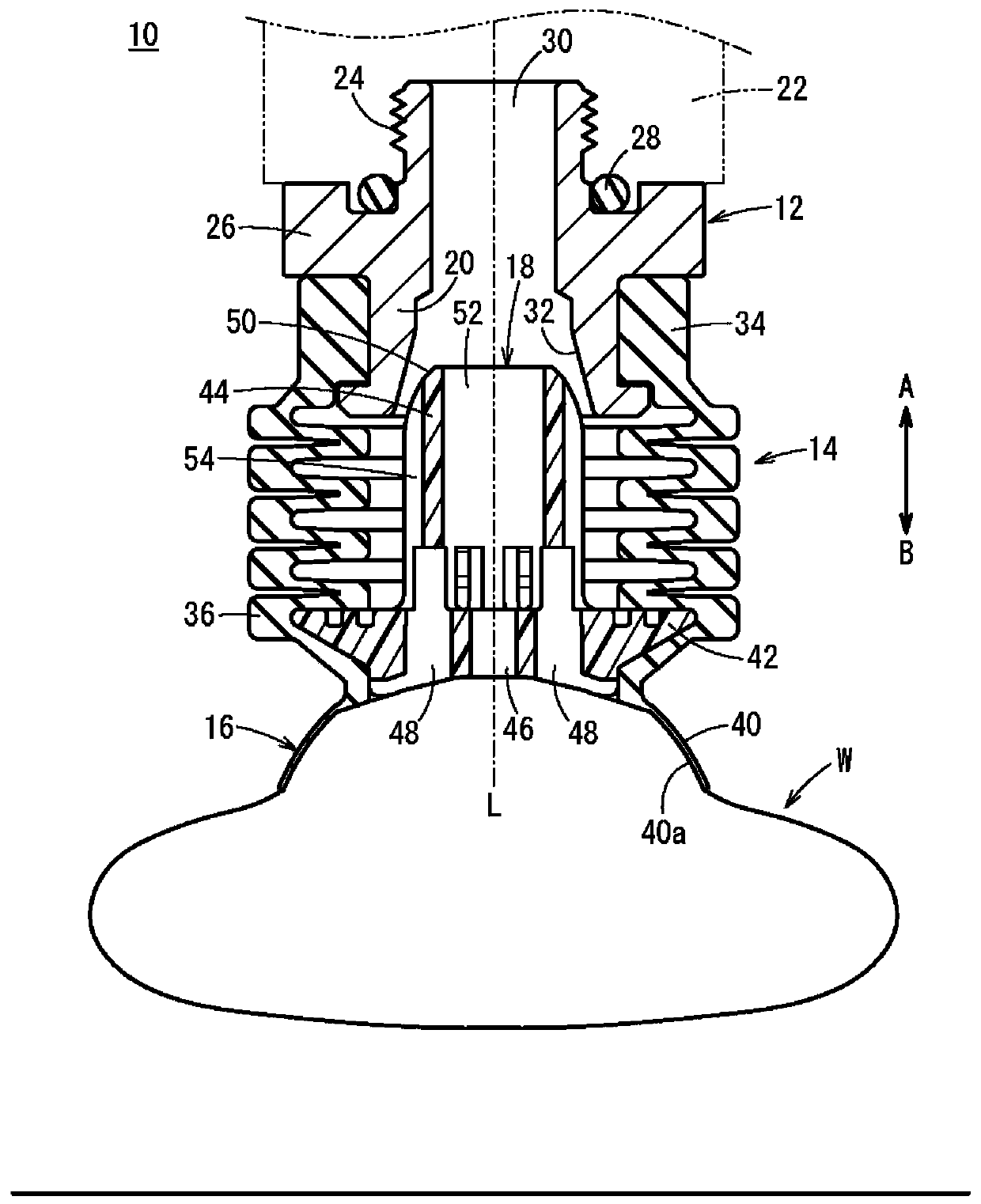

[0019] Such as Figure 1 ~ Figure 4 As shown, the suction device 10 includes: an adapter (main body) 12 connected to a negative pressure supply device (not shown) through piping, a bellows 14 connected to the lower end of the adapter 12, and a bellows 14 formed on the bellows 14. A pad portion (adsorption portion) 16 at the lower end portion (front end), and an attachment (tilting member) 18 accommodated inside the bellows 14 and the pad portion 16 .

[0020] The adapter 12 is formed, for example, in a cylindrical shape made of a metal material, and has a connecting portion 20 connected to the bellows 14 at its lower end, and a threaded portion 24 connected to a joint 22 at its upper end. In addition, a flange portion 26 protruding in a direction perpendicular to the axial direction (directions of arrows A and B) is formed between the coupling portion 20 and the threaded portion 24 in the adapter 12 .

[0021] In addition, a seal ring 28 is attached to the end surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com