Construction method for steel ladle beam supporting structure

A construction method and beam support technology, applied in the direction of pillars, columns, pier columns, etc., can solve the problems that the joints between the main section steel and the support section steel cannot be filled, it is difficult to control the uniformity of concrete materials, and the difference in concrete height and density. Achieve the effect of improving construction efficiency, reducing construction difficulty and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

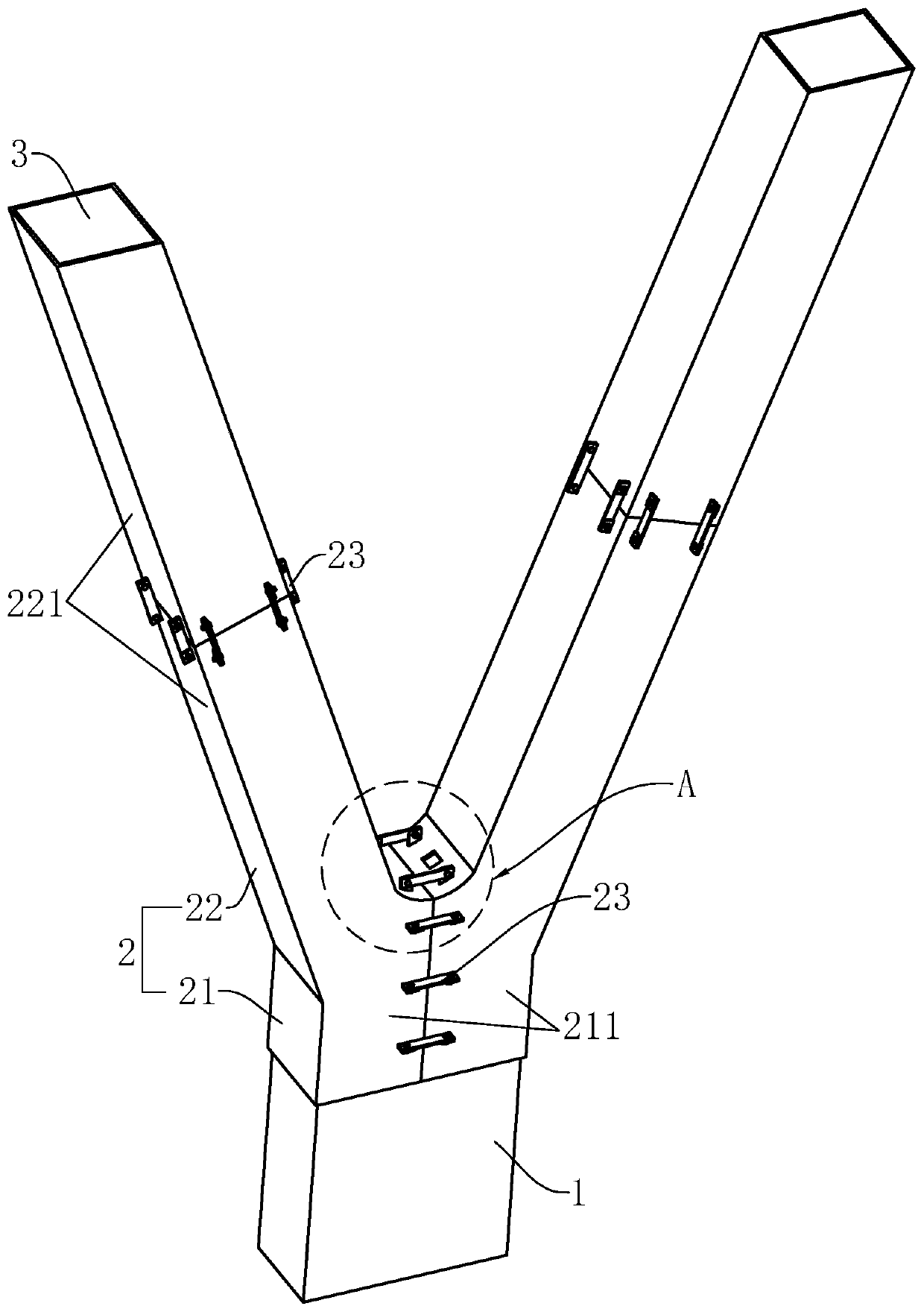

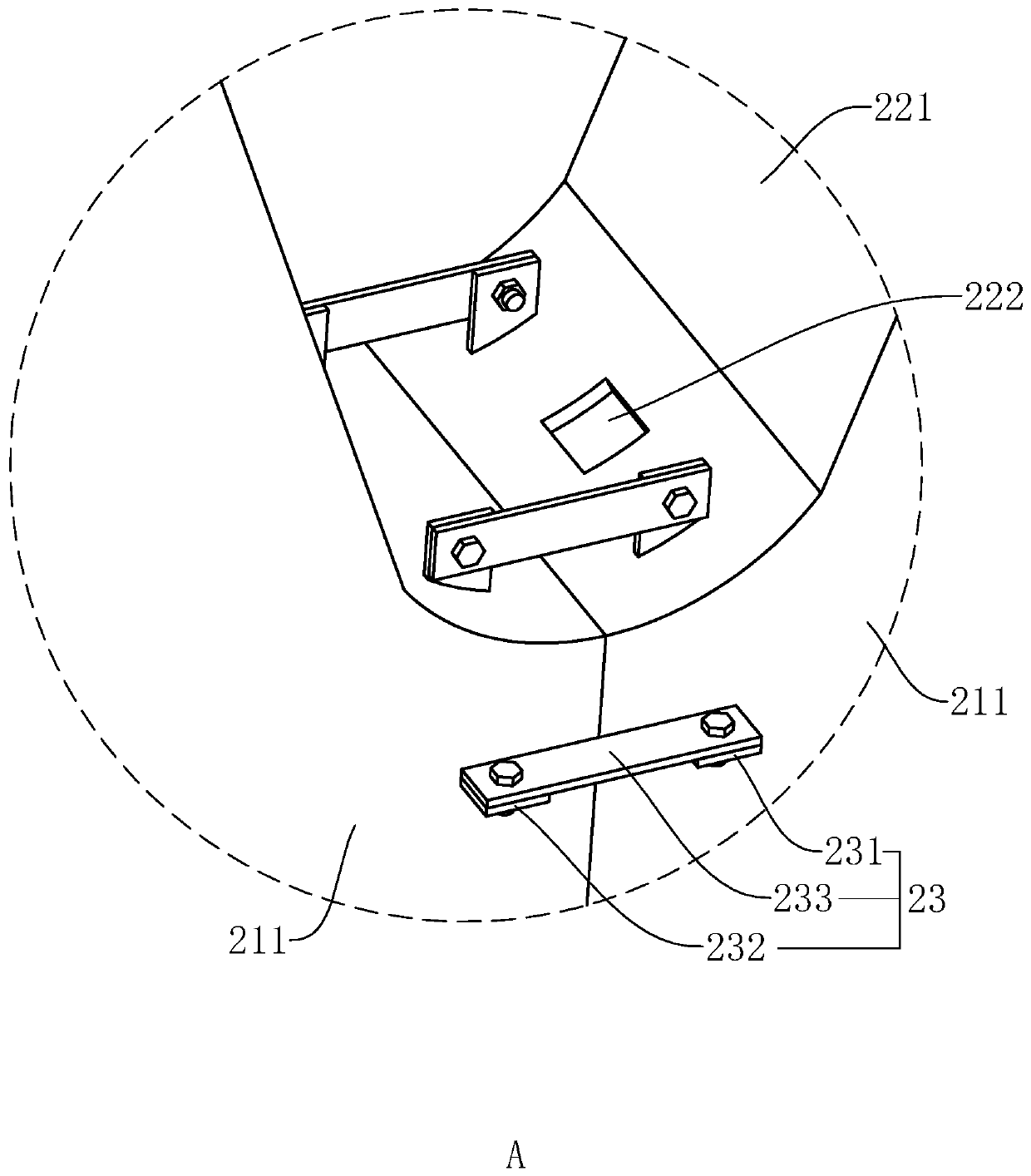

[0043] Such as figure 1As shown, this embodiment introduces a ladle column support structure, which includes a main concrete structural column 1 and an outsourcing steel section 2. The main concrete structural column 1 is integrally connected above the ground, and above the main concrete structural column 1 is integrally connected with two The above supporting columns 3 are introduced in this embodiment by taking two supporting columns 3 as an example. The outsourcing section steel 2 includes main section steel 21 and support section steel 22 , the main section steel 21 is wrapped on the outside of the main concrete structural column 1 , and the support section steel 22 is wrapped on the outside of the support column 3 . The ladle column support structure of this structure uses a main concrete structural column 1 to support multiple support columns 3, and sets the main section steel 21 to wrap the main concrete structural column 1, and sets the support section steel 22 to wrap...

Embodiment 2

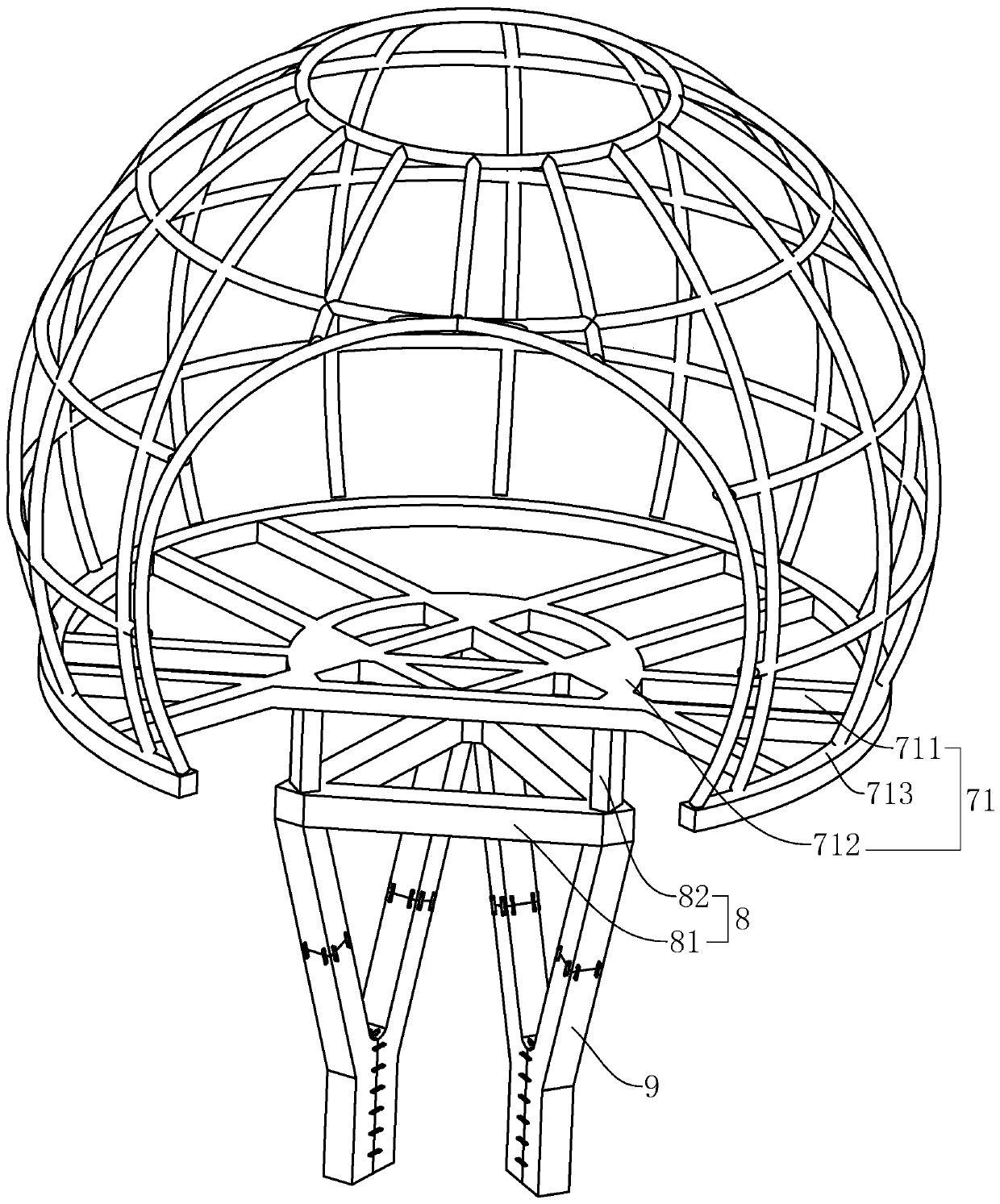

[0052] Such as image 3 As shown, this embodiment introduces a lecture hall structure, including a ladle column support structure 9, a viewing platform 8 and a lecture hall 7, the viewing platform 8 is located above the ladle column support structure 9, and the lecture hall 7 is located on the viewing platform 8, the structure of the ladle column support structure 9 is as described in Embodiment 1. The ladle column support structure 9 includes two, and the two ladle column support structures 9 are used to stably support the viewing platform 8, and the occupied support space Smaller, viewing platform 8 can provide viewing space and the number of floors, while lecture hall 7 is the main viewing point.

[0053] Such as image 3 As shown, structurally, the lecture hall 7 includes a bottom support structure 71 and a top support structure 72, and the bottom support structure 71 includes criss-cross second support beams 711 and arc-shaped third support beams 712 and fourth support b...

Embodiment 3

[0056] This embodiment introduces a construction method of a steel clad beam support structure, including the following steps.

[0057] S1. Binding steel bars, installing the main section steel 21 and the support section steel 22, the specific steps are as follows.

[0058] S11. Combine figure 1 and Figure 4 As shown, at first the reinforcement of the main concrete structural column 1 is bound, and the formwork is supported, and the lower part of the main concrete structural column 1 is poured with concrete;

[0059] S12, demoulding, binding the reinforcing bar of support column 3;

[0060] S13. Dividing the parting surface of the main section steel 21 along the vertical direction into a plurality of main section steel splices 211, the main section steel splices 211 are welded together with the lower end of the support section steel 22, and the support section steel 22 is respectively socketed on different supports On the outer side of the steel bar of column 3, the main s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com