Suction nozzle device for welding head of chip mounting equipment

A technology of equipment and welding head, which is applied in the field of suction nozzle device of the welding head of SMT equipment, which can solve the problems of disassembly and assembly affecting the efficiency of inspection, affecting the processing efficiency, and shutting down.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

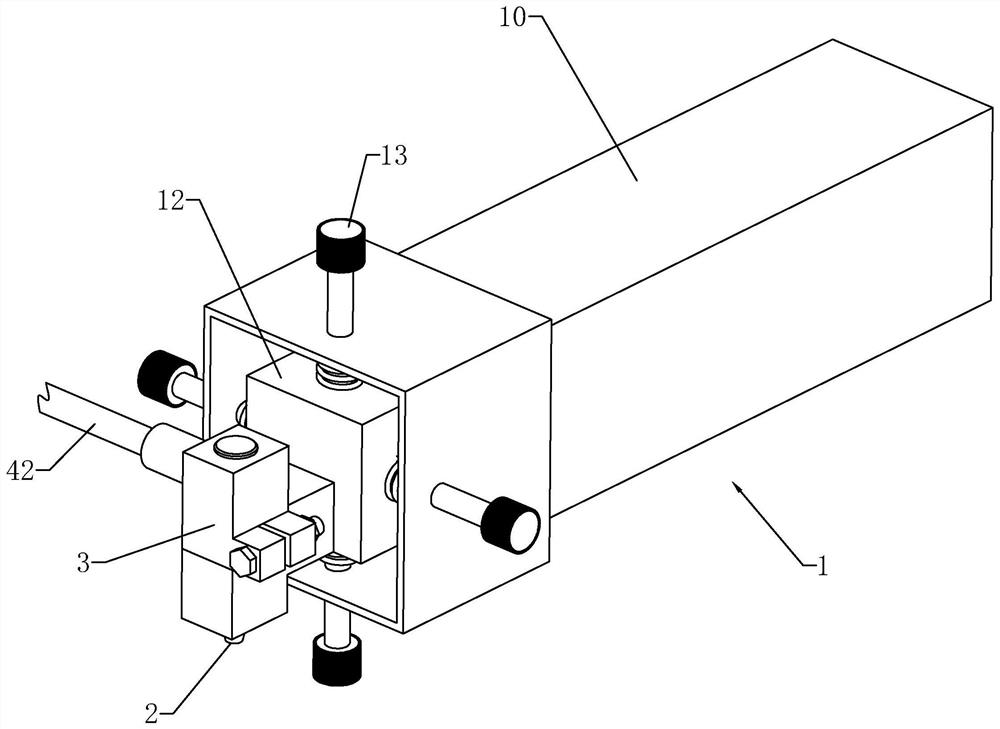

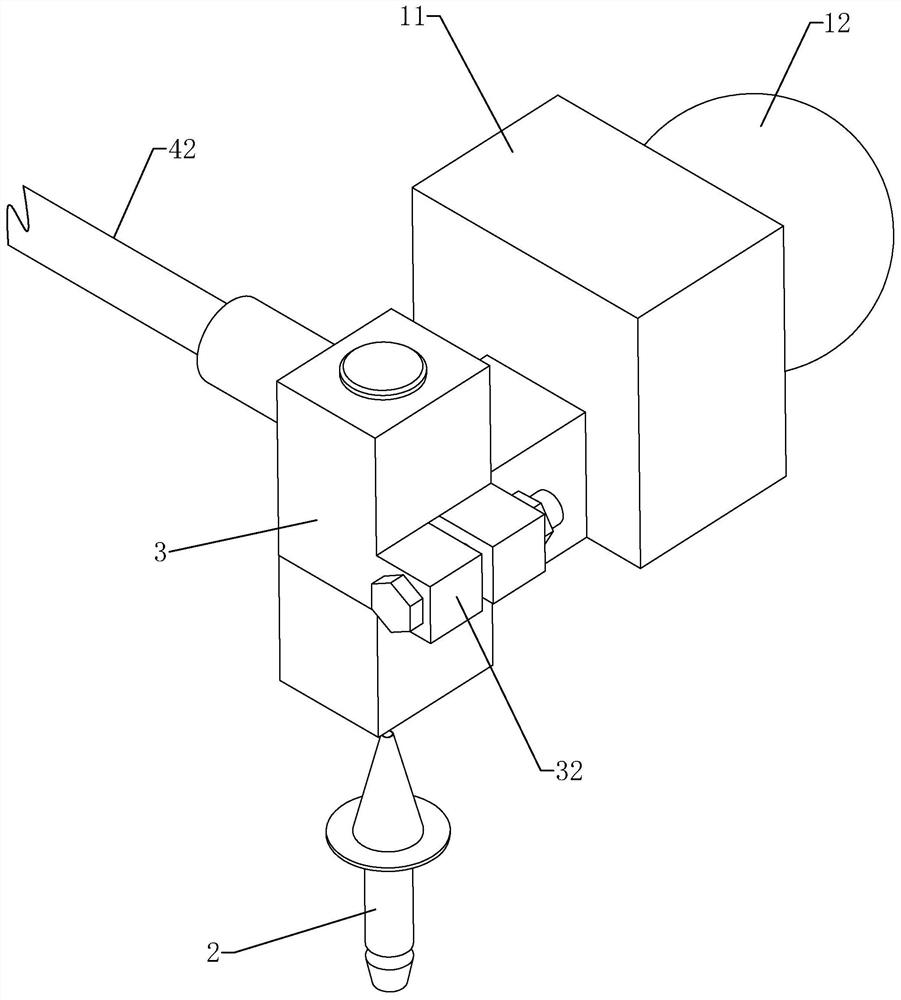

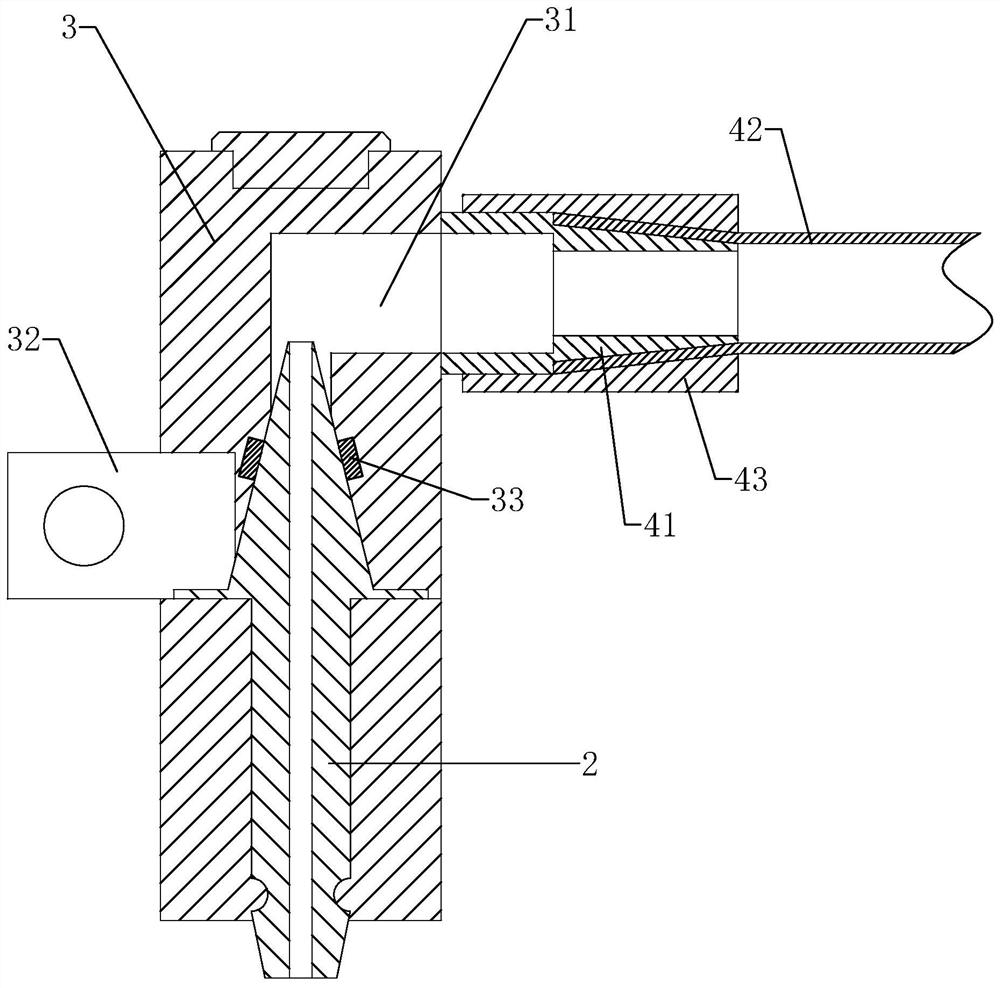

[0023] Example: Reference Figure 1-3 , a nozzle device for a soldering head of a patch device, comprising a connecting arm 1, a nozzle rod 2 fixed to a fixed block 3 and vertically inserted into the fixed block 3. The fixed block 3 is provided with an L-shaped cavity 31 , and the upper end of the nozzle rod 2 is plugged into the vertical section of the cavity 31 . The horizontal section corresponding to the cavity 31 on the fixed block 3 is concentrically welded with a connecting pipe 41. The connecting pipe 41 includes a tapered section and a threaded section. The air pipe 42 is sleeved on the fixed section. The sleeve 43 is used to fix the air tube 42 on the connecting tube 41 . The sealing sleeve 43 is sleeved on the air pipe 42 , and then the sealing sleeve 43 is screwed on the connecting pipe 41 , and the air pipe 42 is clamped between the sealing sleeve 43 and the connecting pipe 41 .

[0024] refer to Figure 1-3 , a sealing ring 33 is provided between the suction n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com