Lubricating oil for fully automatic pumping lubrication system equipment and preparation method thereof

A lubricating system, fully automatic technology, applied in the field of lubricating oil, can solve problems such as inability to truly lubricate and protect mechanical equipment joints, inapplicability of fully automatic pumping lubrication systems, poor adhesion of engine oil or hydraulic oil, etc., which is not easy to achieve Effects of dripping, improvement of low-temperature fluidity, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

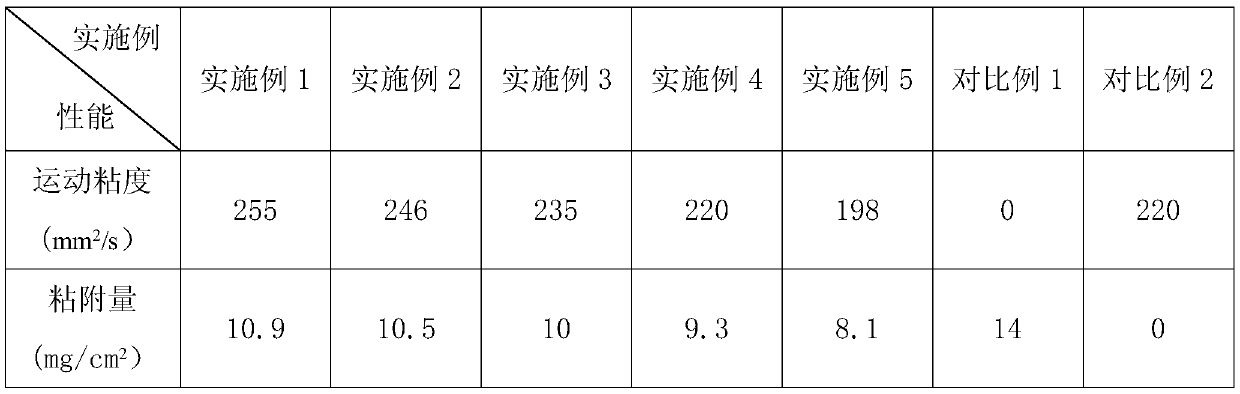

Embodiment 1

[0032] In Example 1, the lubricating oil comprises the following components by weight: 68.9% high-viscosity base oil, 15.9% low-temperature low-viscosity base oil, 4.7% 12-hydroxystearic acid, 3.7% polyisobutylene adhesive, 2.6% Lithium hydroxide (solution), 0.4% liquid polymer phenol antioxidant, 3.7% crystal antiwear agent and 0.1% oil-soluble red toner.

[0033] The preparation method step of lubricating oil is as follows:

[0034] Step 1: Weigh the following components by weight percentage: 42.3% high-viscosity base oil, 26.6% high-viscosity base oil, 15.9% low-temperature low-viscosity base oil, 4.7% 12-hydroxystearic acid, 3.7% polyisobutylene adhesive , 0.4% liquid polymer phenol antioxidant, 2.6% lithium hydroxide solution, 3.7% crystal antiwear agent and 0.1% oil-soluble red toner;

[0035] Step 2: Add the above-mentioned weighed 12-hydroxystearic acid and 42.3% high-viscosity base oil in the first heating container;

[0036] Step 3: heat up to 95°C, and stir at con...

Embodiment 2

[0045] In Example 2, the lubricating oil comprises the following components by weight: 66.7% high-viscosity base oil, 18.5% low-temperature low-viscosity base oil, 4.5% 12-hydroxystearic acid, 3.6% polyisobutylene adhesive, 2.6% Lithium hydroxide (solution), 0.4% liquid polymer phenol antioxidant, 3.6% crystal antiwear agent and 0.1% oil-soluble red toner.

[0046] The preparation method is basically the same as in Example 1.

Embodiment 3

[0047] In Example 3, the lubricating oil comprises the following components by weight: 65.1% high-viscosity base oil, 20.5% low-temperature low-viscosity base oil, 4.4% 12-hydroxystearic acid, 3.5% polyisobutylene adhesive, 2.5% Lithium hydroxide (solution), 0.4% liquid polymer phenol antioxidant, 3.5% crystal antiwear agent and 0.1% oil-soluble red toner.

[0048] The preparation method is basically the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com