Backlash measurement and adjustment method and device

A measurement method and technology of backlash, applied in the direction of measurement devices, transmission parts, belts/chains/gears, etc., can solve the problems of expensive and complicated test benches, and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0058] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the various embodiments of the present invention will be described in detail below with reference to the accompanying drawings. However, a person of ordinary skill in the art can understand that, in each embodiment of the present invention, many technical details are proposed for the reader to better understand the present application. However, even without these technical details and various changes and modifications based on the following embodiments, the technical solutions required by the claims of this application can be realized.

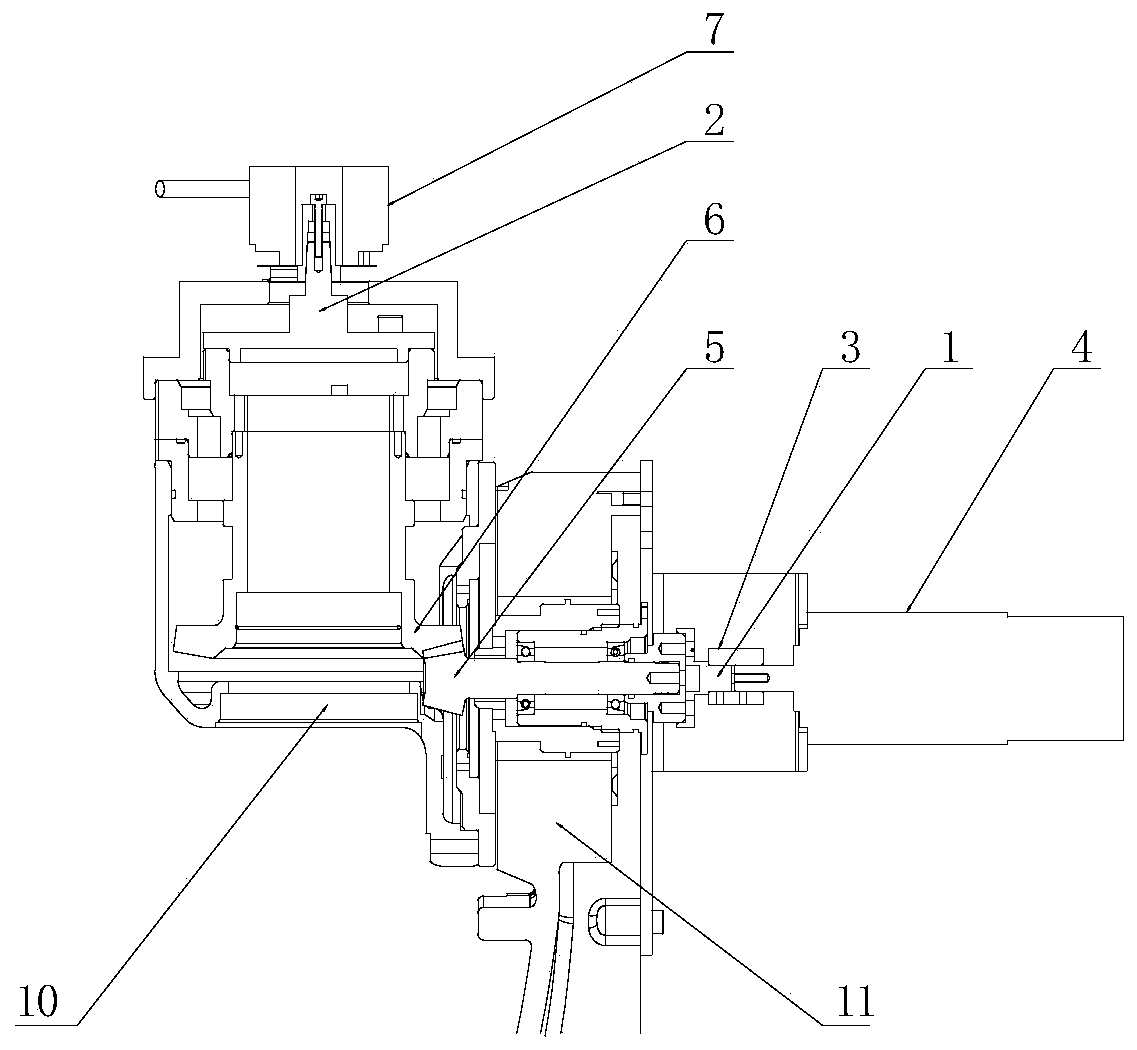

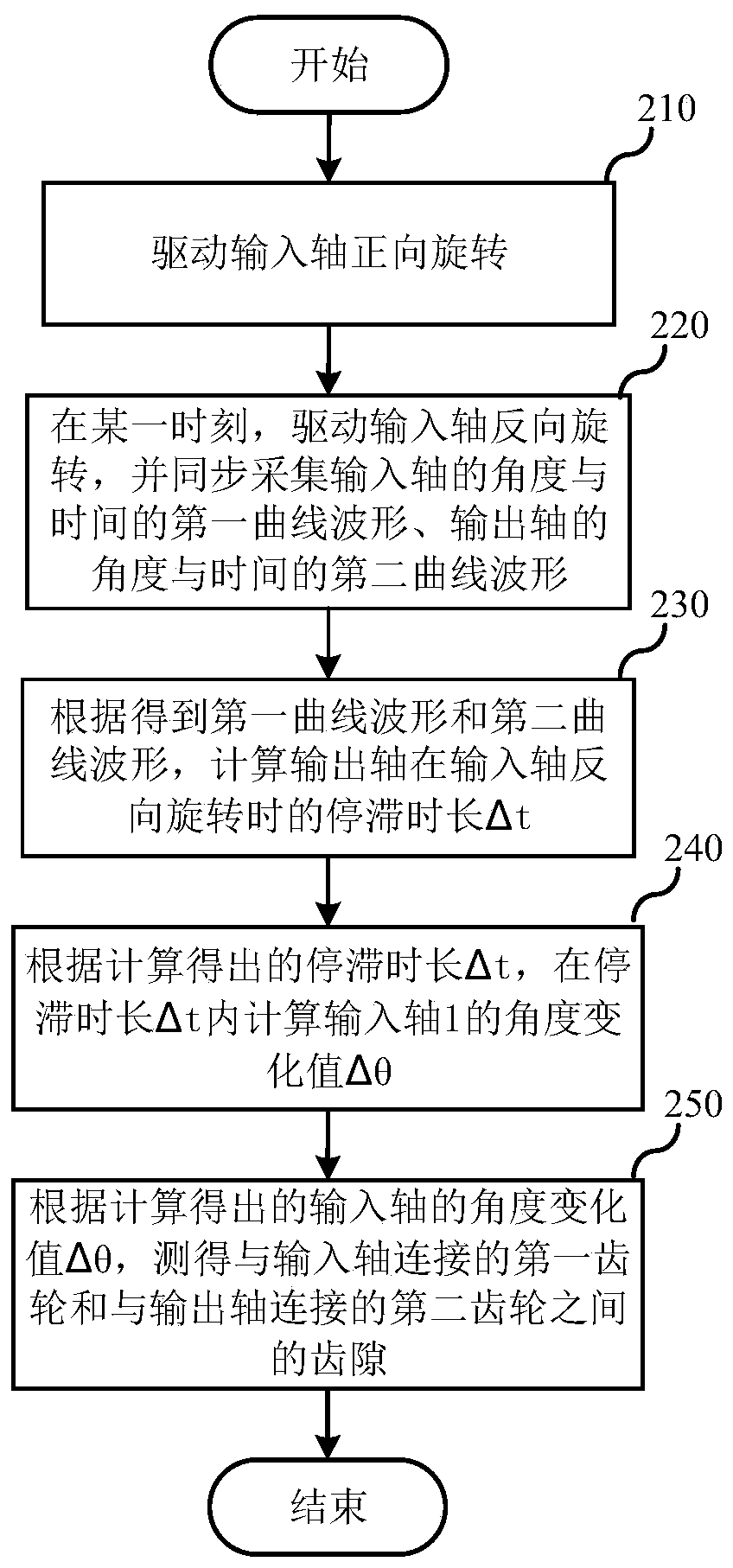

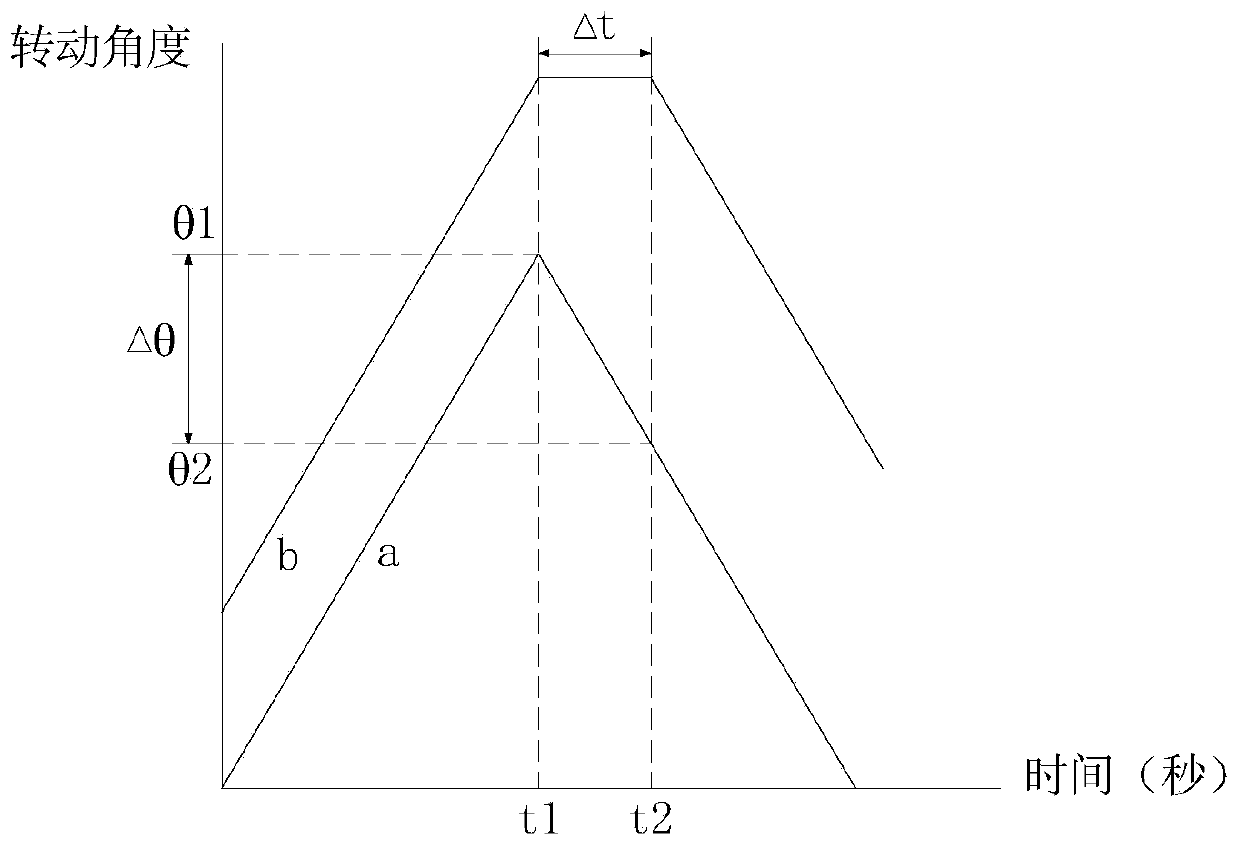

[0059] The first embodiment of the present invention relates to a backlash measurement method, which can be used for example figure 1 Of course, the robot shown can also be used in other precision transmission mechanisms. by figure 1 It is not difficult to see that the first transmission gear 5 is arranged in the robot arm 11, and the sec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap