Agricultural chemical fertilizer bag-breaking and mixing device

A technology for mixing devices and agricultural chemical fertilizers, applied in mixers, transportation and packaging, chemical instruments and methods, etc., can solve the problems of complicated bag breaking process and inconvenient removal of packaging bags, so as to avoid mutual impact and wide applicability , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

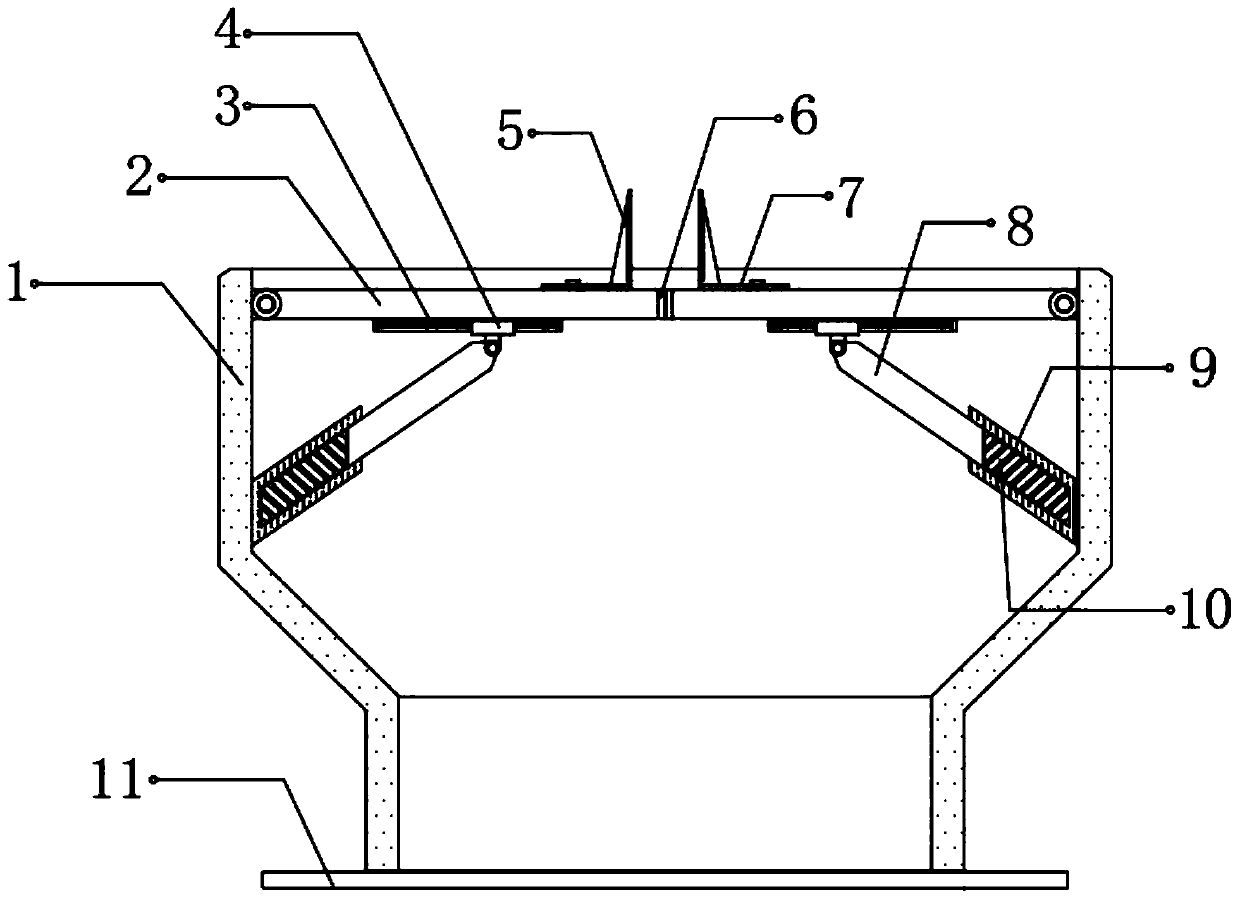

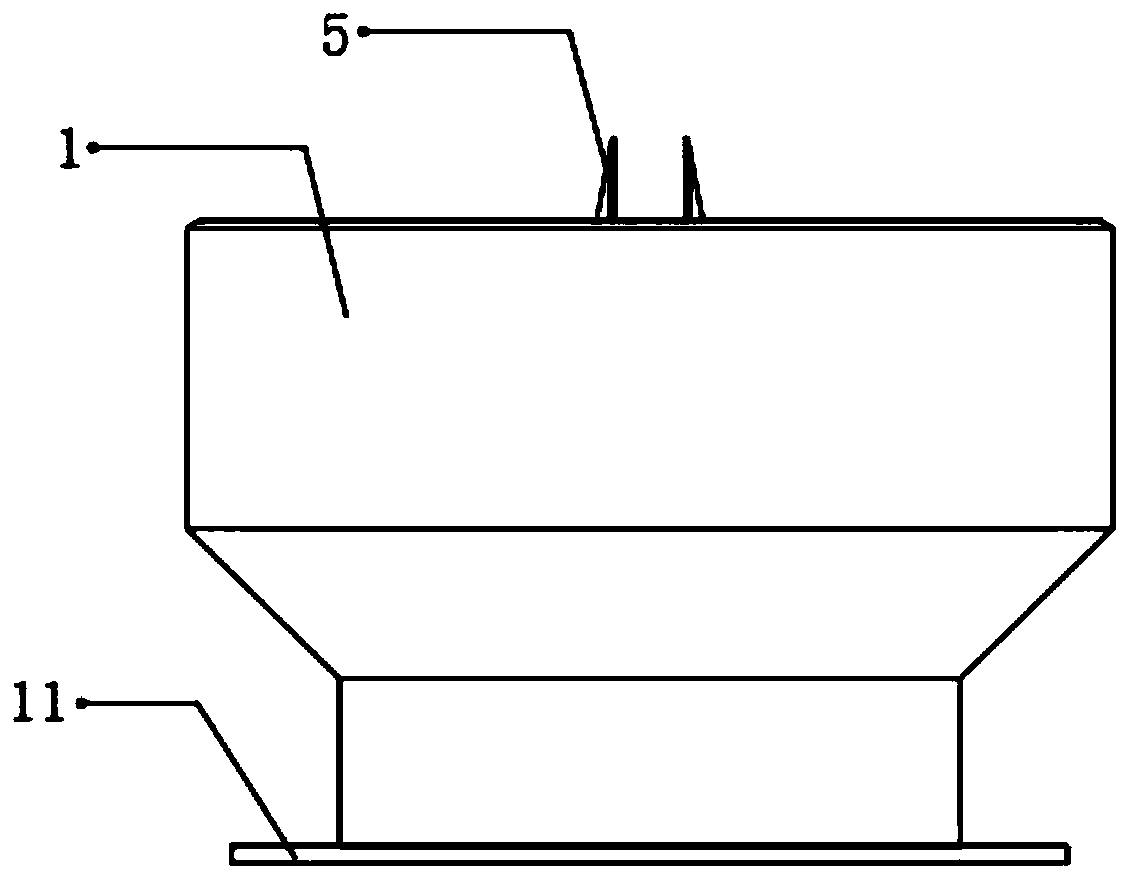

[0025] refer to Figure 1-2 , an agricultural chemical fertilizer bag-breaking mixing device, comprising an upper hopper 1 and a first base 11, the first base 11 is welded to the outer wall at the bottom of the upper hopper 1, the top of the inner wall on both sides of the upper hopper 1 is hinged with a flap 2, and the two The adjacent ends of the two flaps 2 are bonded with rubber pads 6, the bottoms of the two flaps 2 are slidingly connected with inserting rods 8, and the middle parts of the inner walls on both sides of the upper hopper 1 are welded with inserting sockets 9, and the two inserting rods 9 are welded. The rods 8 are respectively inserted into the insides of the two inserting sleeves 9, and the insides of the two inserting sleeves 9 are provided with springs 10. The bottom ends of the two inserting rods 8 are in contact with the tops of the two springs 10 respectively, and the two turning Blades 5 are fixedly connected to the top of one side of the plate 2, the...

Embodiment 2

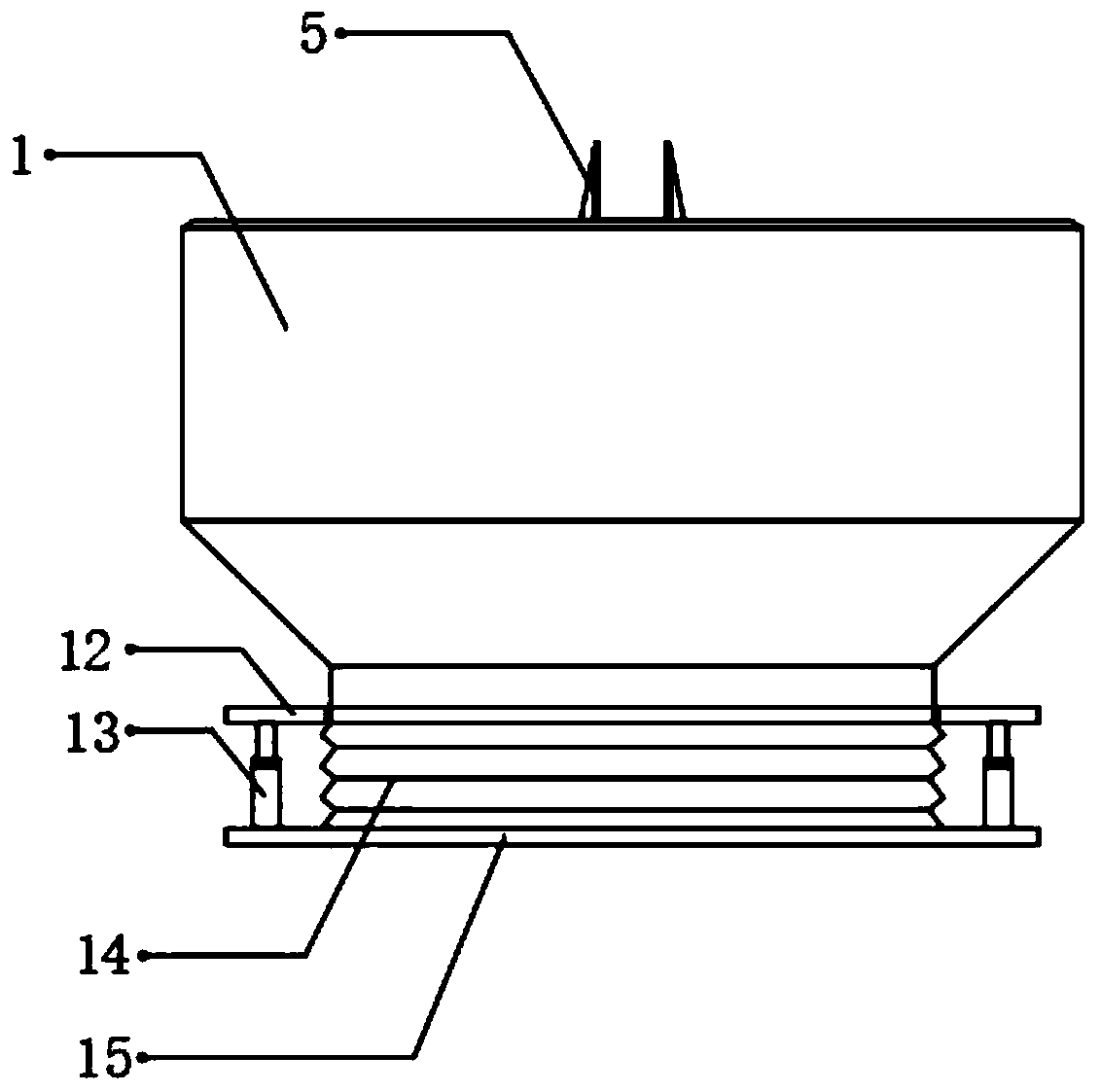

[0031] refer to image 3 , an agricultural chemical fertilizer bag-breaking mixing device. Compared with Embodiment 1, the bottom of the upper hopper 1 is set as a bellows 14, and the outer wall of the bottom of the bellows 14 is fixedly connected with a second base 15. The second base 15 Both sides of the top are fixedly connected with electric push rods 13, and the tops of the two electric push rods 13 are fixedly connected with connecting pieces 12, and the two connecting pieces 12 are respectively welded on both sides of the outer wall of the bottom of the upper hopper 1.

[0032] Working principle: The loading hopper 1 is installed on the feeding place of the mixing device through the second base 15. Since the bellows 14 can be freely expanded and contracted within a certain range, the expansion and contraction of the electric push rod 13 can be controlled to control the expansion of the loading hopper 1. The height is adjusted to give the unit a wide range of applicabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com