Roller assembly and side approaching machine

A technology of rollers and components, which is applied in the field of the structure of side-by-side machines, can solve the problems such as the rollers cannot be disassembled, and achieve the effect of avoiding production accidents and avoiding detachment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] In the following, the present invention will be further described in conjunction with the drawings and specific implementations. It should be noted that, provided that there is no conflict, the following embodiments or technical features can be combined to form new embodiments. .

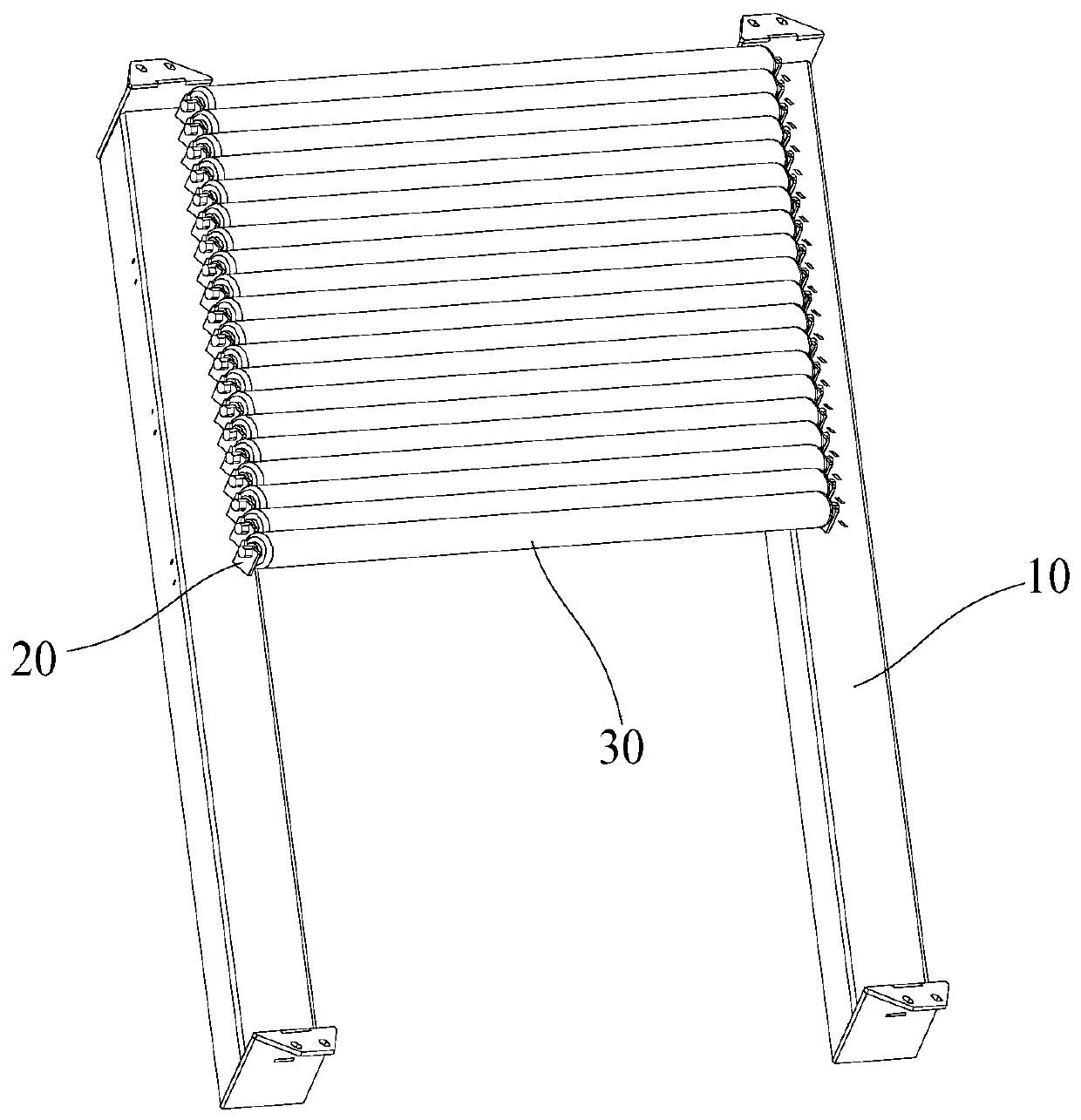

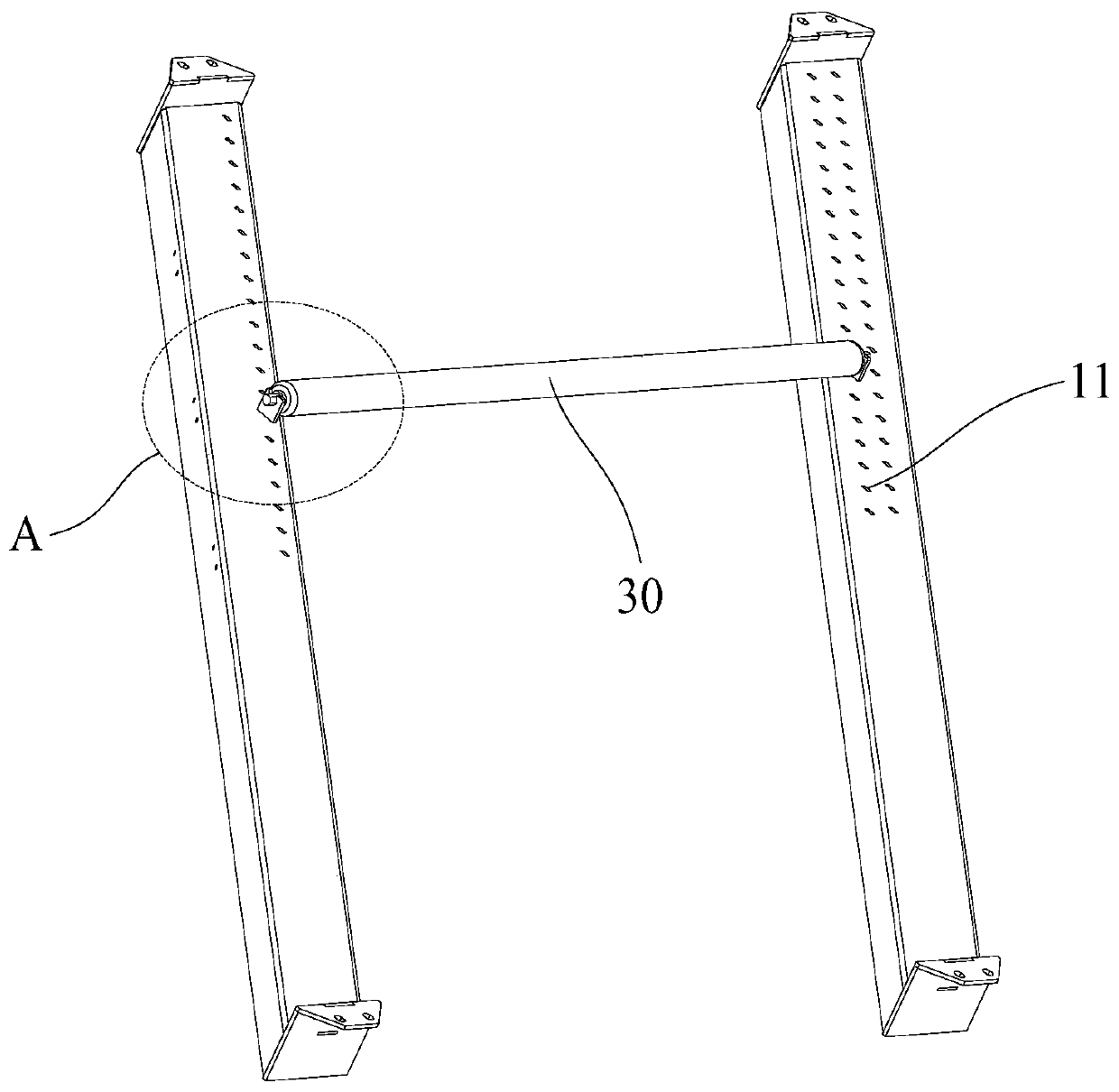

[0028] See Figure 1 to Figure 4 The embodiment of the present invention provides a roller assembly 1. The roller assembly 1 includes two support rods 10, a number of clamping seats 20, and a number of rollers 30. Each support rod 10 is provided with a number of The card seat 20 is provided with a card slot 21 on the side of the card seat 20 away from the support rod 10. The roller 30 can be detachably installed in the card slot 21 to facilitate later maintenance of the side machine. The roller 30 can be removed from the card slot 21 at any time Come down.

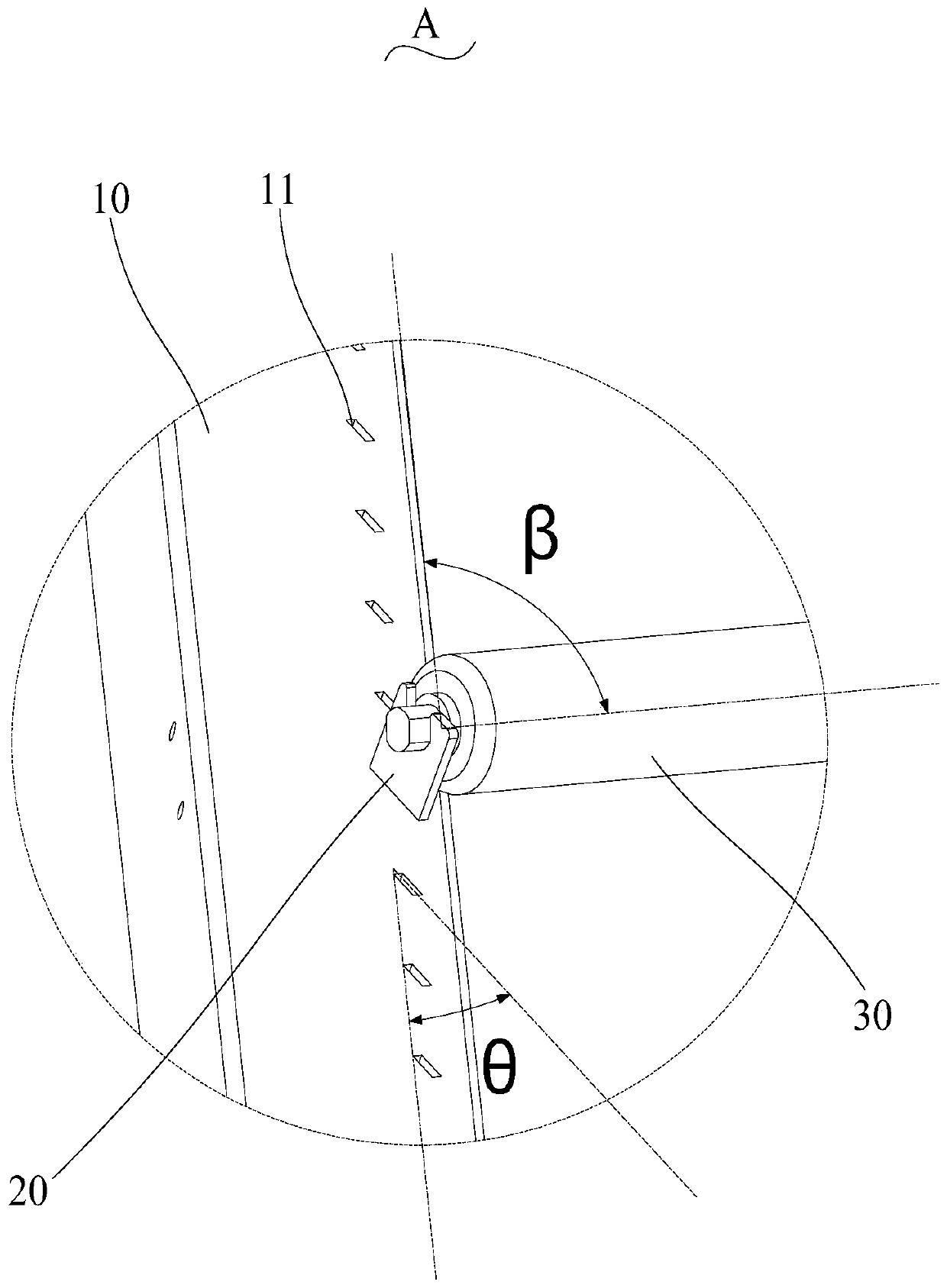

[0029] See further Figure 5 to Figure 7 The card slot 21 includes two parallel groove side surfaces 211 and a groove bottom surface 212 co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap