Spinning yarn arrangement device

A sorting device and hollow shaft technology, which is applied in the direction of thin material handling, transportation and packaging, and delivery of filamentous materials, etc. It can solve the problems of affecting the winding efficiency, yarn knotting or breaking, and the inability to pull out the yarn. , to achieve the effect of pulling the yarn easily and improving the winding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

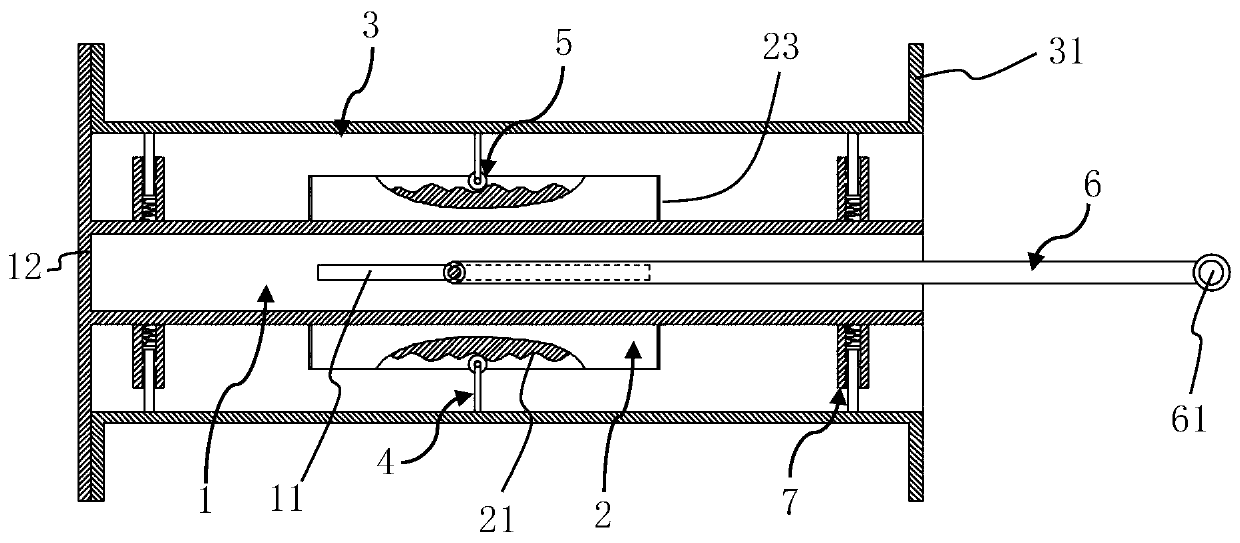

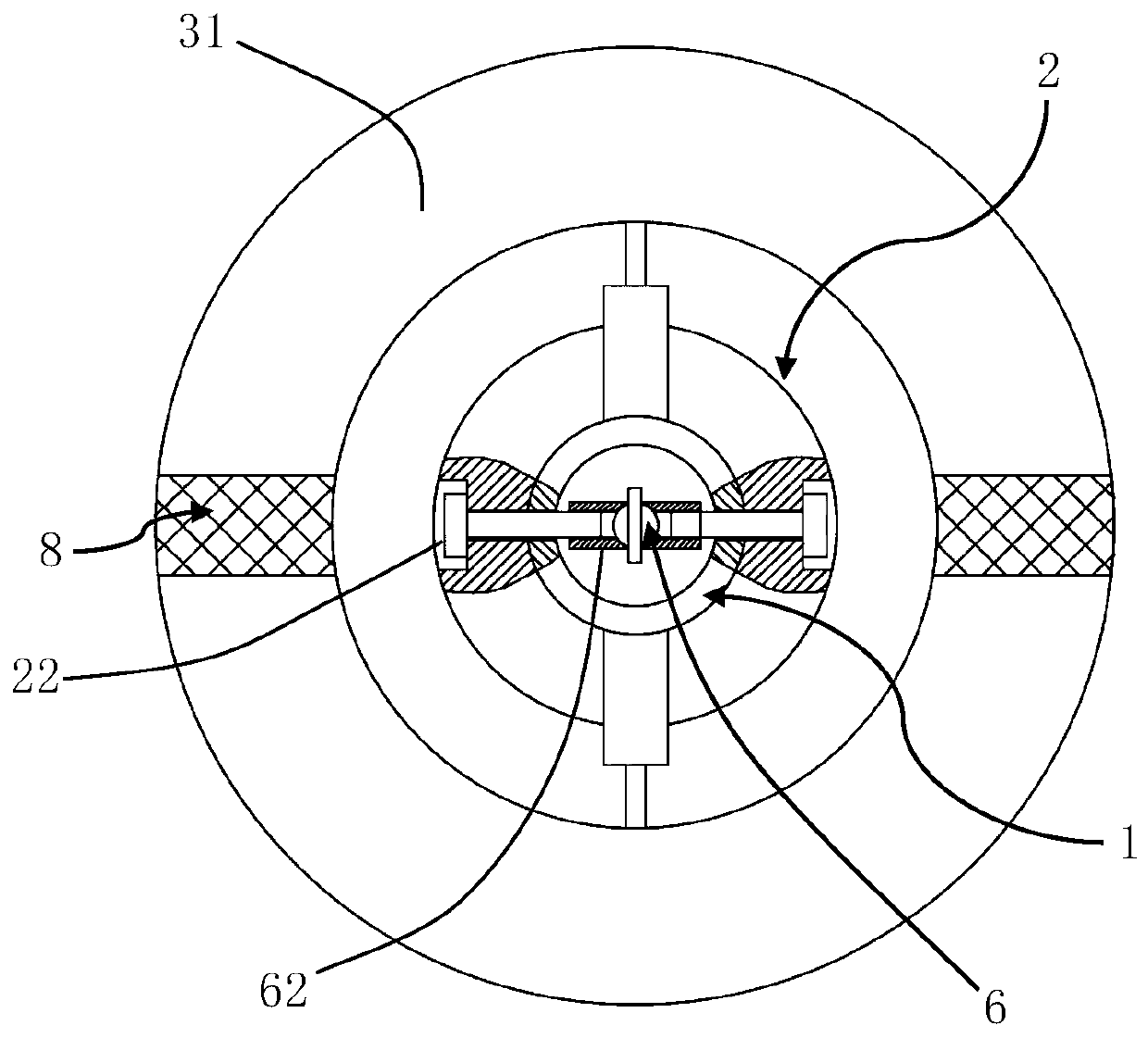

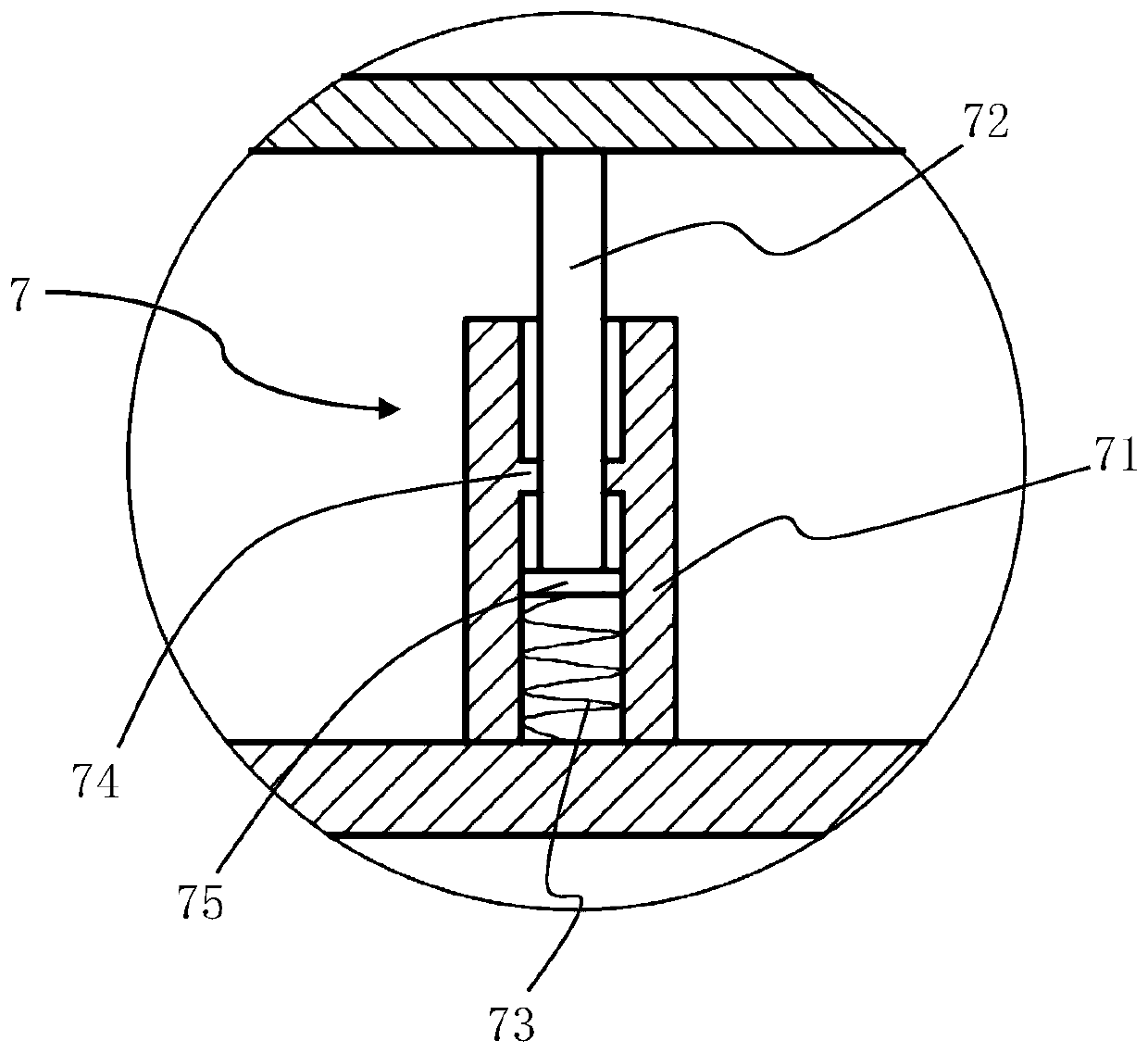

[0025] Such as figure 1 , figure 2 and image 3 As shown, this embodiment discloses a spinning finishing device, which includes a hollow shaft 1 and a sleeve coaxially arranged from the inside to the outside. A wave-shaped contact surface 21 is provided in the direction; the above-mentioned casing includes two supporting plates 3 uniformly distributed on the circumference, the supporting plates 3 are arc-shaped, and a connecting rod 4 is arranged on the inner periphery of the supporting plate 3, and the connecting rod 4 The end away from the support plate 3 is rotatably connected with a roller 5, and the roller...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap