Novel cam divider

A cam divider, a new type of technology, applied to belts/chains/gears, mechanical equipment, transmission devices, etc., can solve the problems of inconvenient processing, production and use, easy wear and tear of indexing cams, and inability to adjust the position of output shafts. Simple, solve the effect of assembly production, convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, the present invention will be described in more detail with reference to the accompanying drawings. This embodiment is only a description of the best implementation mode of the present invention, and does not limit the scope of the present invention in any way.

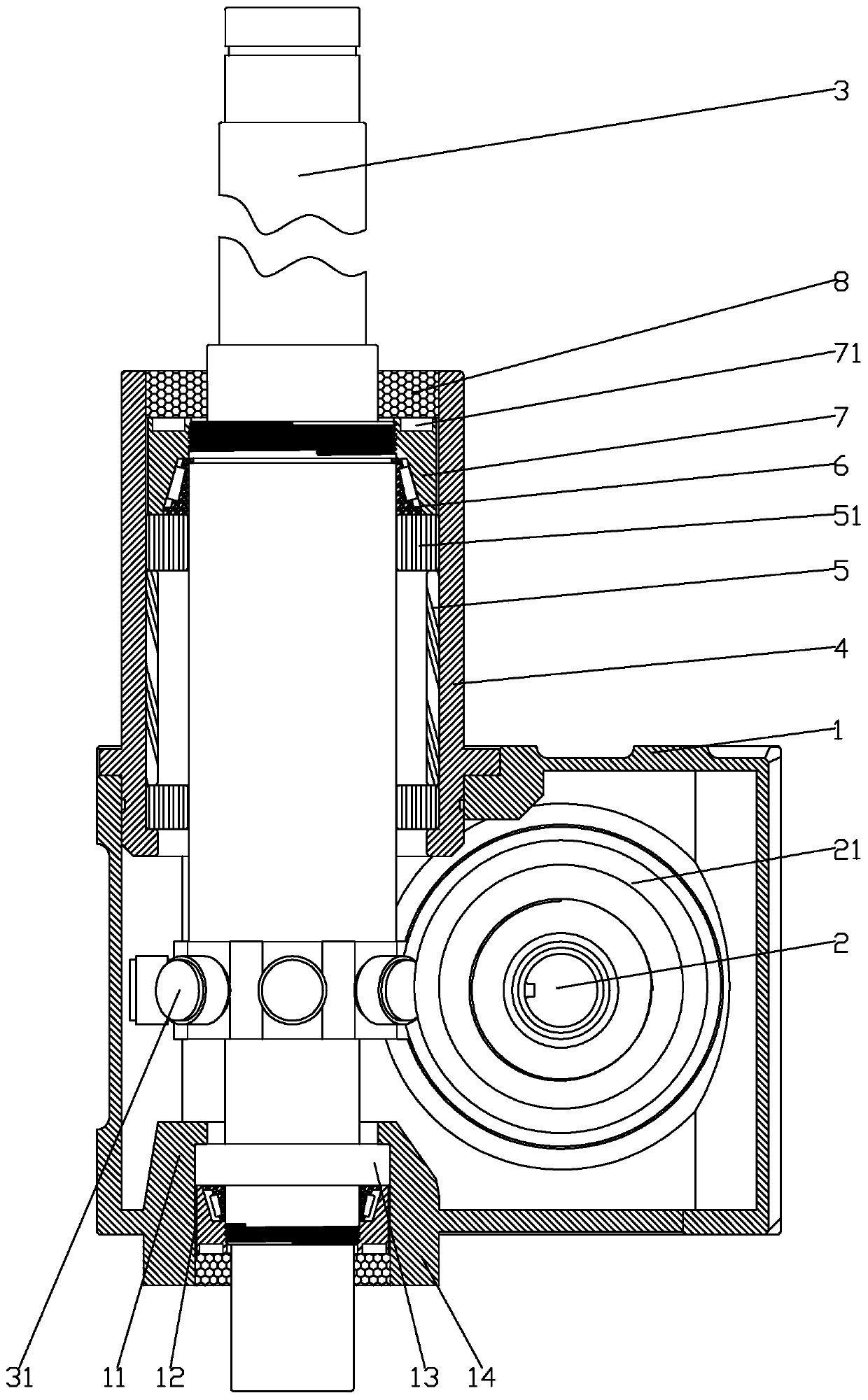

[0016] Such as figure 1 As shown, a new type of cam divider includes a housing 1, the housing 1 is provided with an input shaft 2 arranged horizontally and an output shaft 3 vertically arranged on one side of the input shaft 2, and the outer circumference of the input shaft 2 is sleeved with The indexing cam 21, the outer circumference of the output shaft 3 is sleeved with the output turret 31 matching the indexing cam 21, the auxiliary sleeve 4 is connected and fixed on one side of the housing 1, and the other side is provided with a fixed base 11, One end of the output shaft 3 passes through the auxiliary sleeve 4, and the other end passes through the fixed base 11. The auxiliary sleeve 4 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com