Flocking chamber of flocking machine

A technology of flocking machine and flocking room, applied in the field of flocking room, can solve the problem of igniting fluff and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

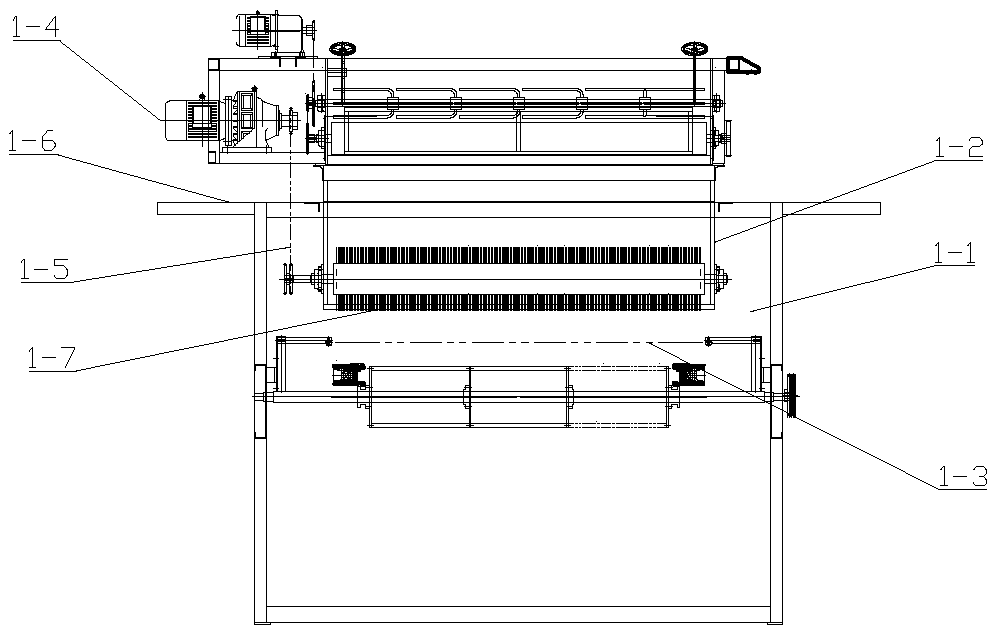

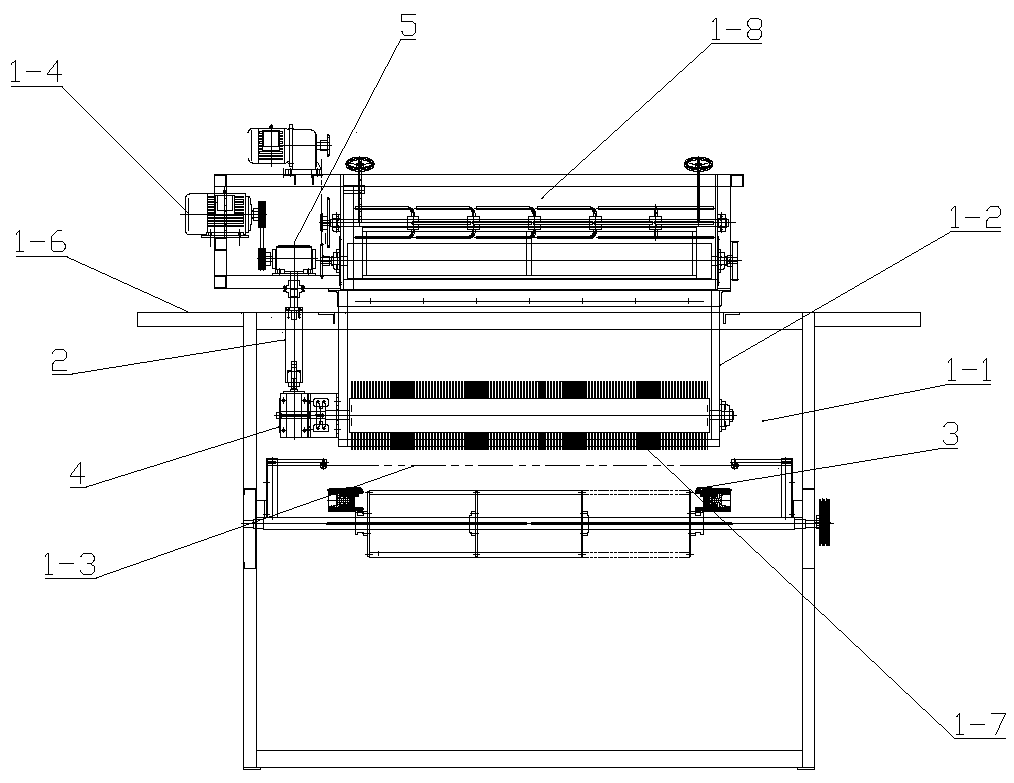

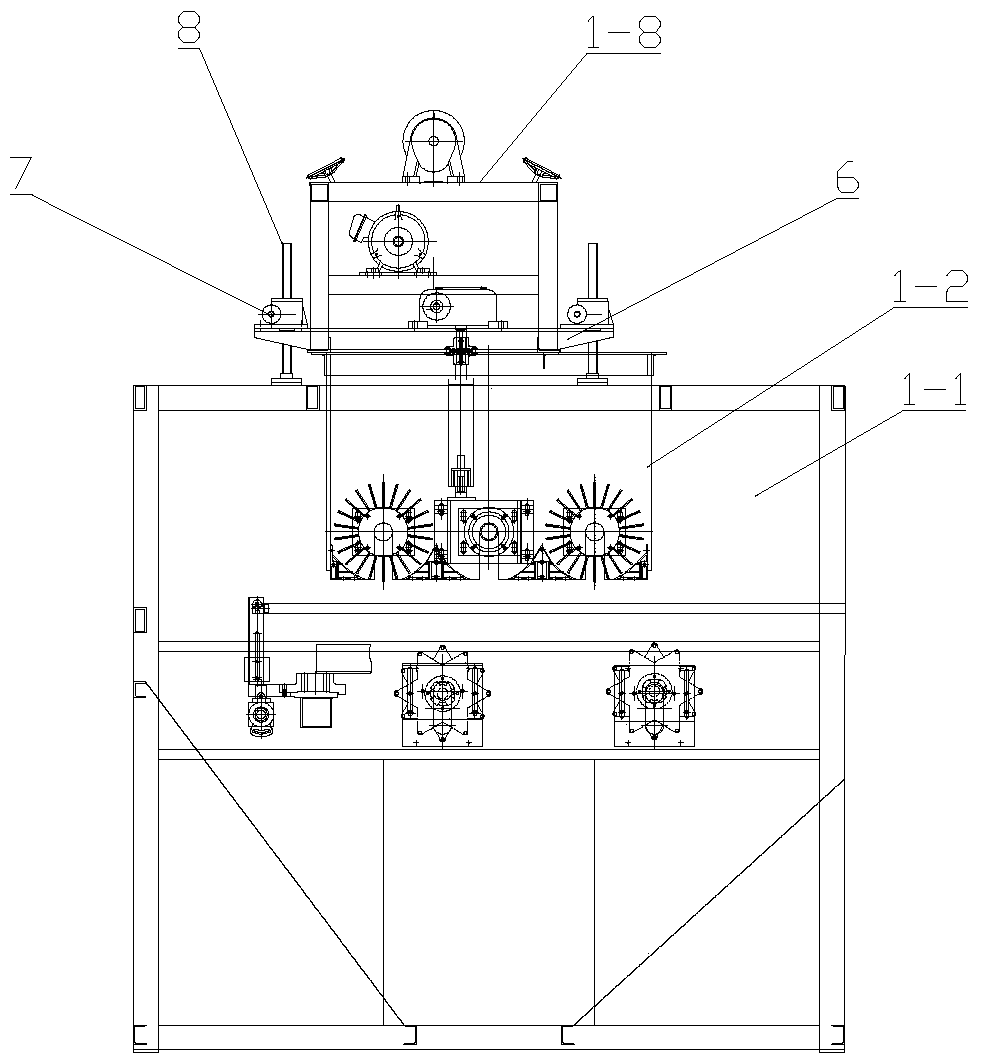

[0016] like figure 2 , image 3 The flocking chamber of the shown flocking machine comprises a brush bucket 1-2, and a brush roller 1-7 is installed in the brush bucket 1-2; Inside the fluff chamber 1-1; the brush motor 1-4, the brush motor 1-4 is located outside the fluff chamber 1-1, the brush motor 1-4 is connected with the brush roller 1-7 through the insulated drive shaft 2, and the insulated drive Axle 2 passes through the housing frame 1-6 of the fluff chamber 1-1.

[0017] Specifically, it includes a metering bucket 1-8 at the top, and metering components are installed in the metering bucket 1-8 for measuring fluff, and a brush bucket 1-2 is connected below the metering bucket 1-8, and the measured fluff Fall into the brush bucket 1-2, and then enter the fluff chamber 1-1 through the brush on the brush roller 1-7. The brush bucket 1-2 is partly located in the fluff chamber 1-1, and partly located in the fluff chamber 1. Above -1, the fluff chamber 1-1 is located be...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap